High-strength polyolefin composite pipe and preparation method thereof

A polyolefin and composite pipe technology, applied in the field of polyolefin pipes, can solve the problems of reduced performance and poor use effect, and achieve the effects of high tensile strength, excellent anti-penetration performance, and improved strength and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

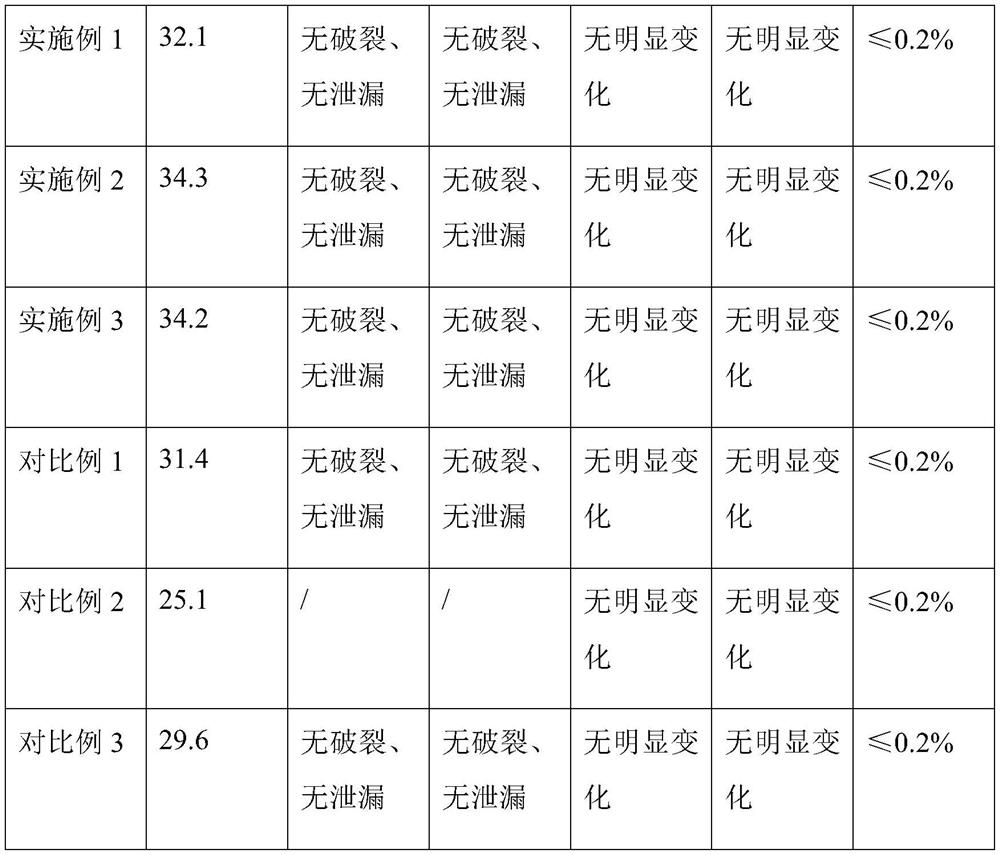

Embodiment 1

[0035] A method for preparing a high-strength polyolefin composite pipe, comprising the following steps:

[0036] (1) Take nickel hydroxide and germanium dioxide, dissolve them in deionized water, add sodium hydroxide, adjust the pH to 11, react at a constant temperature for 60 hours under sealed conditions, and the reaction temperature is 210 ° C, cool naturally after the reaction, transfer the sample and filter , washed with deionized water, and dried in vacuum at 100°C for 5 hours to obtain a reinforcing material; the molar ratio of germanium and nickel is 2:3;

[0037] (2) Take reinforcing material and ethanol, ultrasonically disperse for 10min, add 3-aminopropyltriethoxysilane, stir and react at 25°C for 5h, centrifuge and wash, vacuum dry, transfer to tetrahydrofuran solvent, ultrasonically disperse for 15min, add Trimellitic anhydride, stirred and reacted at 25°C for 7 hours, collected by centrifugation, washed with deionized water, and dried in vacuum to obtain carboxy...

Embodiment 2

[0045] A method for preparing a high-strength polyolefin composite pipe, comprising the following steps:

[0046] (1) Take nickel hydroxide and germanium dioxide, dissolve them in deionized water, add sodium hydroxide, adjust the pH to 11, react at a constant temperature for 65 hours under sealed conditions, and the reaction temperature is 205 ° C, cool naturally after the reaction, transfer the sample and filter , washed with deionized water, and dried in vacuum at 103°C for 4.5 hours to obtain a reinforcing material; the molar ratio of germanium and nickel is 2:3;

[0047] (2) Take reinforcing material and ethanol, ultrasonically disperse for 15min, add 3-aminopropyltriethoxysilane, stir and react at 28°C for 4.5h, centrifuge and wash, vacuum dry, transfer to tetrahydrofuran solvent, ultrasonically disperse for 18min, Add trimellitic anhydride, stir and react at 25°C for 7.5 hours, collect by centrifugation, wash with deionized water, and dry in vacuum to obtain carboxylated...

Embodiment 3

[0055] A method for preparing a high-strength polyolefin composite pipe, comprising the following steps:

[0056] (1) Take nickel hydroxide and germanium dioxide, dissolve them in deionized water, add sodium hydroxide, adjust the pH to 12, react at a constant temperature for 70 hours under sealed conditions, and the reaction temperature is 200 ° C, cool naturally after the reaction, transfer the sample and filter , washed with deionized water, and dried in vacuum at 105°C for 4 hours to obtain a reinforcing material; the molar ratio of germanium and nickel is 2:3;

[0057] (2) Take reinforcing material and ethanol, ultrasonically disperse for 20min, add 3-aminopropyltriethoxysilane, stir and react at 30°C for 4h, centrifuge and wash, vacuum dry, transfer to tetrahydrofuran solvent, ultrasonically disperse for 20min, add Trimellitic anhydride, stirred and reacted at 25°C for 8 hours, collected by centrifugation, washed with deionized water, and dried in vacuum to obtain carboxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com