Zero-discharge sewage treatment process for industrial parks

A technology for industrial parks and sewage treatment, applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of single function of water treatment agent, waste of resources, high cost, etc., to achieve treatment Good effect, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 As shown, a treatment agent for zero-discharge sewage treatment in industrial parks is made of the following materials in parts by weight: 20 parts of polyaluminum chloride; 5 parts of lime; 20 parts of flocculant; 30 parts of adsorbate ; 25 parts of bentonite, the flocculant is powdered alum, and the particle size of the powdered alum is not more than 0.3mm, and the adsorbate is a mixture of woody activated carbon and activated alumina.

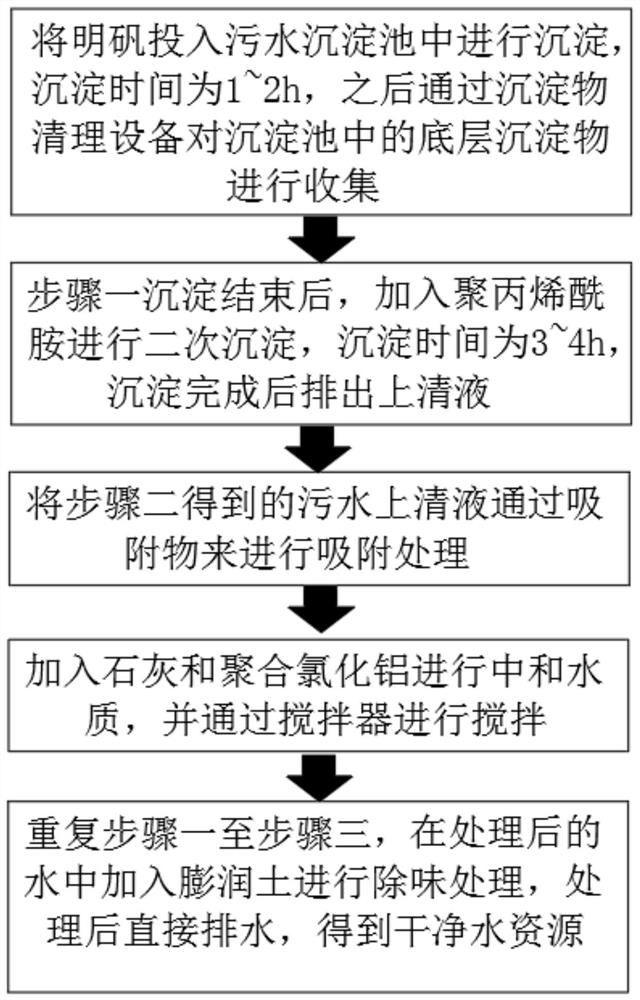

[0046] A zero-discharge sewage treatment process for industrial parks, characterized in that: the process steps are as follows:

[0047] Step 1, put alum into the sewage sedimentation tank for sedimentation, the sedimentation time is 1-2h, and then collect the bottom sediment in the sedimentation tank by sediment cleaning equipment;

[0048] Step 2. After the precipitation in step 1 is completed, add polyacrylamide for secondary precipitation. The precipitation time is 3 to 4 hours. After the precipitation is complet...

Embodiment 2

[0054] Embodiment 2 is a further improvement to Embodiment 1.

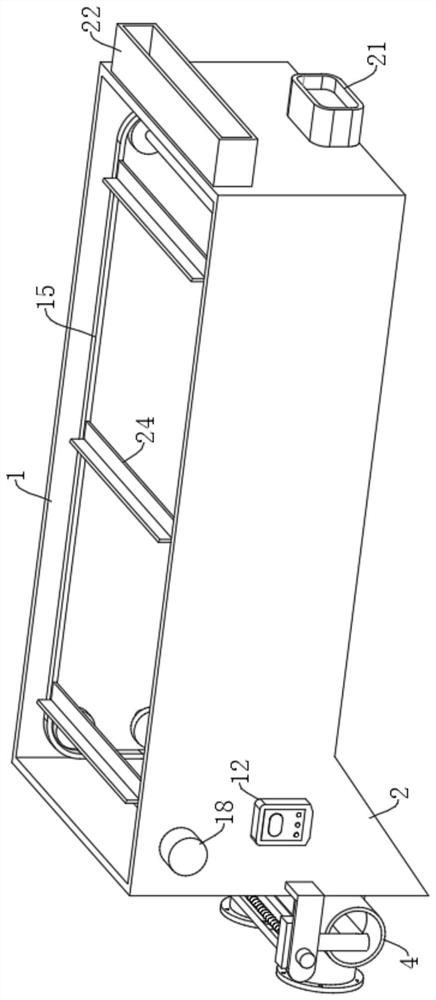

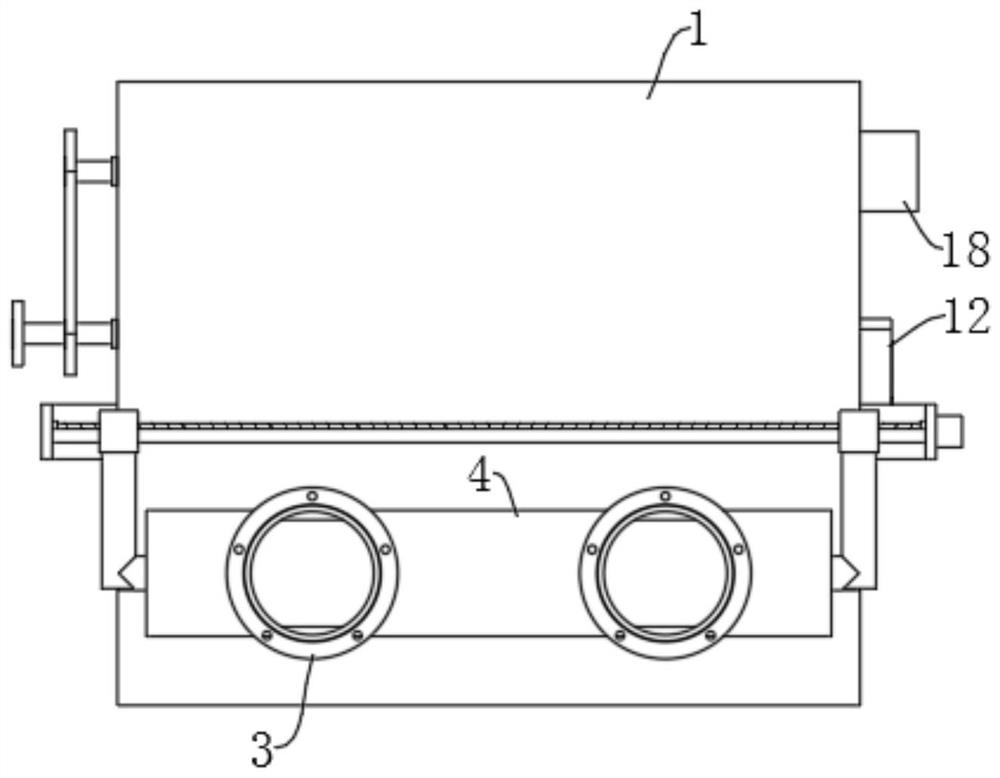

[0055] Such as figure 2 , 3 , 8, 9, 10, and 11 show a zero-discharge sewage treatment device for industrial parks. The treatment device is the sediment cleaning equipment in step 1, including a sedimentation tank 1 and a collection bucket 2. The collection bucket 2 is connected to the At the bottom end of the sedimentation tank 1, the collecting bucket 2 is connected with a sedimentation discharge mechanism, and a sedimentation cleaning mechanism is arranged in the sedimentation tank 1; the sedimentation discharge mechanism includes a set of pipelines 3, connecting pipes 4, a set of pistons 5, and a set of L-shaped connections. Rod 6, a group of movable blocks 7 and drive components, a group of pipes 3 are symmetrically distributed and their ends are all connected to the inside of the sedimentation tank 1, the connecting pipe 4 spans the two pipes 3, and the pipes 4 are connected to the two pipes 3, A group of ...

Embodiment 3

[0059] Embodiment 3 is a further improvement to Embodiment 1.

[0060] Such as Figure 4 , 5 , 6, 7, 9, 10, 11, the flocculant also includes polyacrylamide. The adsorbate consisted of 30% wood activated carbon and 70% activated alumina. The signal of the second motor 18 is connected to the controller 12, and the controller 12 can control the operation of the second motor 18, and the sedimentation tank 1 is provided with a scum cleaning mechanism. The scum cleaning mechanism comprises a plurality of L-shaped push pedals 24, and a plurality of L-shaped push pedals 24 are equidistantly distributed between two groups of chains 15, and the L-shaped push pedal 24 ends are fixedly connected with the chains 15 respectively. The number of L-shaped push plate 24 and scraper 17 is all set to three. The surface of L-shaped push plate 24 and scraper 17 is all coated with anti-rust paint layer. When the two groups of chains 15 run synchronously, a plurality of L-shaped push plates 24 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com