Hydrophilic cooling agent and application thereof

A hydrophilic and cooling agent technology, applied in the field of hydrophilic cooling agents, can solve problems such as affecting lighting, uneven lighting, and poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

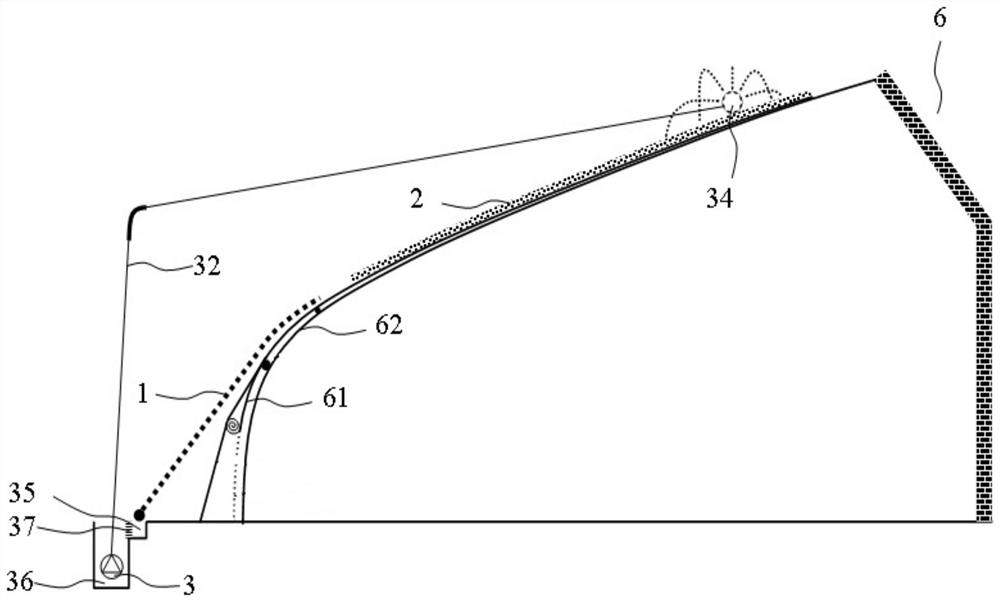

Image

Examples

Embodiment 1

[0145] This example is a hydrophilic cooling agent, which forms (weight) of: 2000 g of tackifier roster glyceryl, 8000 g of hydrophilic binder mica powder.

[0146] The preparation method of the above hydrophilic cooling agent is to heat the 2000G tackifier rosin glyceride, melt, mix well with 8000 g of hydrophilic material mica powder, and let it cool.

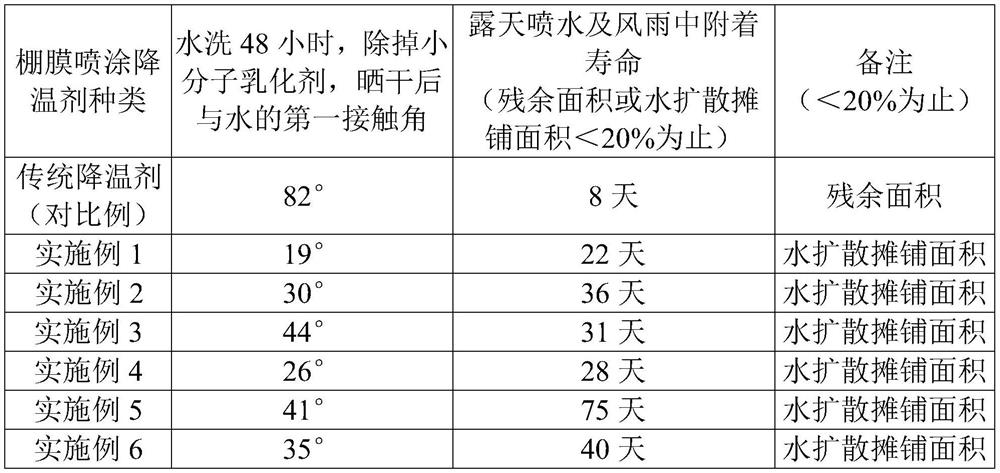

[0147] The hydrophilic cooling agent of the present embodiment is solid. When used, dissolved with 8000 g of solvent banana water, shake well, coated on the outer surface of the shed film, and then formed, formed a hydrophilic cooling agent layer. The first contact angle of the hydrophilic cooling agent layer and the water was measured = 19 °.

Embodiment 2

[0149] In this embodiment, a hydrophilic cooling agent is comprised of a plasticizer of 2500 g of a tackifier, 200 g to dissolve the tackifier, 6800 g of hydrophilic base, 100 g photocatalyst, 200g reversible Membrane, 30G crosslinking inhibitor, 100G crosslinking accelerator, 300g emulsifier, 40 g of sterilizing algae agent, 30 g of colorant, 50 g of infrared light reflective material, 10g photoluminescent material, 50g reversible thermochromic material, 1500g organic Solvent, 15000 g of water, 10g defoamer. Among them, the tackifier is a terpene resin, and the plasticizer that can dissolve the tackifier is diisooctyl oxide, the hydrophilic base is diatomaceous earth, and the photocatalyst is anatase-type titanium dioxide, reversible crosslinking. The film forming agent is a polyvinyl alcohol-boric acid composite system, and the crosslinking inhibitor is acetic acid. The crosslinking promoter is acetate. The emulsifier is a nonylphenol polyoxyethylene ether. The sterilizing algor...

Embodiment 3

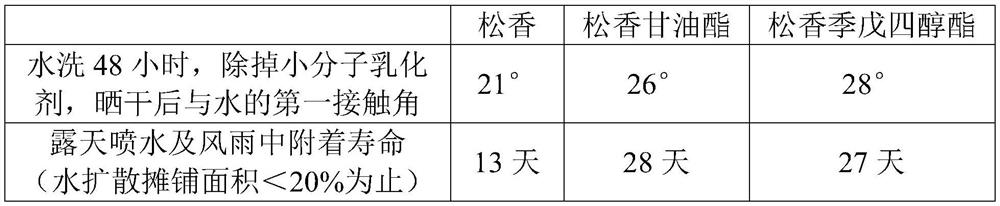

[0153] This example is a hydrophilic cooling agent, which composition (weight) is: 5000g tackifier pine, 25000 g of hydrophilic material hydrophilic silica sol (20% dry matter content, ie, water 20000g, containing hydrogen silica sol) Dry substance 5000g), 1000 g of water, 300 g of emulsifier nonylphenol polyoxyethylene ether.

[0154] The preparation method of the above hydrophilic cooling agent is: the 10000 g of water, 5000 g of tackifier, 300 g of emulsifier is heated and emulsified, drying cool, and then mixing with 25000 g of a hydrophilic silica sol.

[0155]The hydrophilic cooling agent of the present embodiment is an emulsion. When used, coated on the outer surface of the shed membrane, after drying, forming a hydrophilic cooling agent layer. Wash the emulsifier, then dry, measure the first contact angle of the hydrophilic cooling agent and the water = 44 °.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com