Pig brain proliferation promoting peptide-brain phospholipid co-production method

A pig brain and phospholipid technology, which is applied to the preparation methods of peptides, chemical instruments and methods, edible phospholipid compositions, etc., can solve the problems of complicated preparation process, influence on product quality, metal ion pollution, etc., and achieves simple preparation process and low cost. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] Wherein the preparation steps of porcine brain proliferation-promoting peptide are,

[0066](d) ultrafiltration is carried out by successively passing the filtrate I in step (c) through a cellulose membrane with a molecular weight of 5000Da~6000Da and a cellulose membrane with a molecular weight of 950Da~1500Da; the inlet pressure in the ultrafiltration process is 2.81Bar~3.05 Bar, the reflux pressure in the ultrafiltration process is 0.53Bar~0.67Bar.

[0067] (e) vacuum drying and dehydrating the ultrafiltered substance in step (d) to obtain extract I, which is porcine brain proliferation-promoting peptide.

[0068] Wherein the more specific preparation steps of porcine brain proliferation-promoting peptide are,

[0069] (d1) ultrafiltration of the filtrate I in step (c) through a cellulose membrane with a molecular weight of 5000Da~6000Da; continuous ultrafiltration until the volume of the filtrate I becomes 1 / 3.5~1 / 3 of the original, to obtain a retentate I and the...

Embodiment 1

[0122] The porcine brain proliferation-promoting peptide-brain phospholipid co-production method includes the following steps,

[0123] (a) select 100g porcine brain and 900ml physiological saline, mix the selected porcine brain and physiological saline in proportion and homogenize for 15min;

[0124] (b) 8U / mg trypsin was added to the homogenized mixture to carry out stirring enzymolysis, the stirring time was 25min, the pH value of the solution in the enzymolysis process was 6-8, the enzymolysis temperature was 45°C, and the enzymolysis time was 5h;

[0125] (c) Filtration I and filter residue I are obtained after the material after enzymolysis is filtered.

[0126] includes steps,

[0127] (f) filter residue I in step (c) is carried out freeze dehydration, get the cold acetone that temperature is -15 ℃~-2 ℃, the filter residue I after cold acetone and freeze dehydration is mixed, the volume consumption of cold acetone is freezing 2.5 times of filter residue 1 volume after...

Embodiment 2

[0136] The volume ratio of ethanol to ammonia water in the alkali ethanol solution is 100:0.5, and other steps and data are the same as in Example 1.

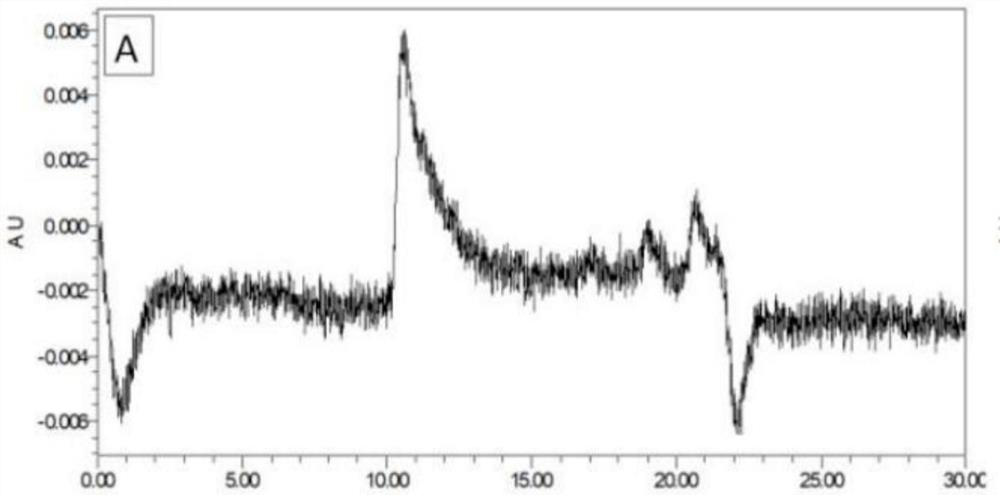

[0137] The contents of phosphatidylcholine (PC), phosphatidylinositol (PI) and phosphatidylethanolamine (PE) in the phospholipid extract of brain detected by HPLC are shown in Table 5;

[0138] Table 5: When the volume ratio of ethanol to ammonia water is 100:0.5, the content of components in the phospholipid extract in the brain

[0139]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com