Bright yellow antibacterial natural color bamboo paper pulp and paper product thereof

A technology of bamboo pulp and natural color, applied in the direction of non-woody plant/crop pulp, papermaking, paper machine, etc., can solve the problems of lignin loss, darkening, black liquor with bad smell, etc., and achieve low effective alkali content and low alkali consumption The effect of low energy consumption and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of bamboo pulp

[0035] Take bamboo chips with a dry raw material quality of 2000Kg, prepare lye with different concentrations through sodium hydroxide, and then heat to 90-95°C to obtain hot lye, and spray the hot lye on bamboo with a rotary nozzle with a flow rate of 20m 3 / hour (high spraying amount infiltration), during the spraying process, the alkali amount absorbed by the bamboo slices is sampled, and when the alkali amount absorbed by the bamboo slices is about 8% of the absolute dry weight of the bamboo slices (the high spraying amount infiltration reaching this value is measured) time), and then reduce the amount of alkali sprayed hot lye to 10m 3 Spray the bamboo chips with a low spray volume at a speed of 1 hour, and the infiltration time of the low spray volume spray is the predetermined total infiltration time minus the high spray infiltration time. The total soaking time of the two sprays is the total soaking time. After ...

Embodiment 2

[0046] Embodiment 2: the test of bamboo pulp antibacterial performance

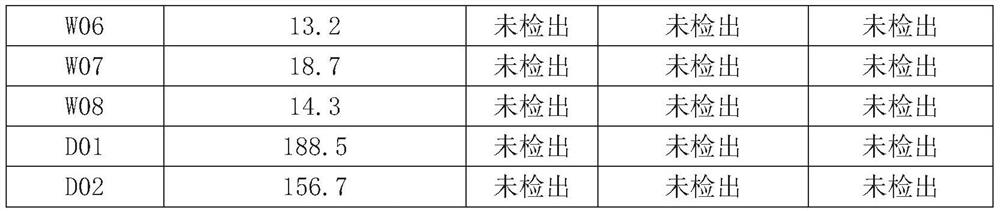

[0047] After the above-mentioned bamboo pulp is passed through the household paper production line to produce toilet paper, the sample toilet paper is numbered W01-W08 according to the bamboo pulp sample number M01-M08, and the natural color paper toilet paper produced by bamboo from two manufacturers in the market is used as a control. , No. D01 and D02, under the same conditions for antimicrobial performance measurement. According to GB / T20810-2018 Appendix C "Determination of microbial indicators" method. The measurement results are shown in Table 3 below.

[0048] Table 3 Antibacterial performance results of toilet paper

[0049]

[0050]

[0051] By testing the toilet paper prepared from the bamboo pulp in Example 1 and the toilet paper on the market, it was found that the microbiological indicators all met the standard requirements. The total number of bacterial colonies in the toilet paper...

Embodiment 3

[0052] Embodiment 3: the paper color test of bamboo pulp

[0053] The bamboo pulp prepared by gained embodiment 1 is copied into 80g / m Disc paper, the disc sheet number that bamboo pulp pulp M01-M08 prepares is Z01-Z08, and the natural color paper that market buys bamboo pulp preparation gets two samples K01 and K02, the lightness coordinate L*, the chromaticity coordinate a*, and the yellow light chromaticity b* are measured by the CHN spec gloss meter. The specific results are shown in Table 4 below.

[0054] Table 4 Paper Color Result Table

[0055] Numbering L* a* b* Z01 80.36 2.57 26.43 Z02 58.60 3.26 27.81 Z03 70.64 2.39 24.59 Z04 65.71 4.99 25.11 Z05 71.13 2.81 26.45 Z06 70.39 3.26 27.81 Z07 68.97 4.30 24.59 Z08 63.25 3.05 25.11 K01 76.64 -1.53 20.91 K02 85.44 0.82 27.81

[0056] By measurement, the color of the paper prepared from the pulp prepared in Example 1 is 63-72 in L*, 2-5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com