Ruthenium-iron bimetallic catalyst and preparation method and application thereof

A bimetallic catalyst and reaction technology, used in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as high operating conditions, quality impact, equipment corrosion, etc. , to achieve the effect of improving conversion rate and selectivity, optimizing selective adsorption, and solving corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a kind of preparation method of ruthenium-iron bimetallic catalyst, comprises the steps:

[0045] Mixing ruthenium carbonyl, activated carbon and the first solvent, performing the first thermal decomposition reaction to prepare ruthenium carbonyl carbon;

[0046] Mixing the carbonyl ruthenium carbon, carbonyl iron and a second solvent, and performing a second thermal decomposition reaction to prepare the ruthenium-iron bimetallic catalyst.

[0047] In some examples, the ruthenium carbonyl is selected from at least one of ruthenium pentacarbonyl and triruthenium dodecacarbonyl. Further, ruthenium carbonyl is triruthenium dodecacarbonyl.

[0048] In some examples, the iron carbonyl is selected from at least one of iron pentacarbonyl and triiron dodecacarbonyl. Further, the iron carbonyl is triiron dodecacarbonyl.

[0049] In some examples, in the ruthenium-iron bimetallic catalyst, the mass percentage of ruthenium is 4%-6%, and the mass percentag...

Embodiment 1

[0064] Add 15mL of acetone and 0.1g of ruthenium dodecacarbonyltriruthenium (0.33mmol) into a 50mL three-necked flask, dissolve and add 1.8g of dry activated carbon, stir at 40°C under argon for 1h, then remove under reduced pressure and collect the acetone , to obtain black powder carbonyl ruthenium carbon.

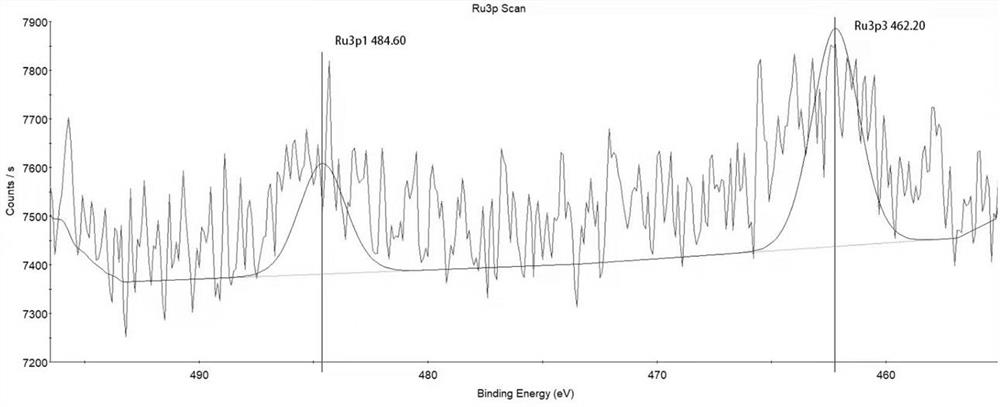

[0065] In another 50mL three-necked flask, add 15g octadecylamine (0.056mol), triiron dodecacarbonyl (0.60mmol) methanol solution containing 0.1g iron (mass concentration 95%) and the aforementioned ruthenium carbonyl carbon, under argon Stir at 60°C for 1 hour to remove methanol, then raise the temperature to 130°C and keep it for 1 hour, and finally raise the temperature to 220°C and keep it for 0.5 hours. C Catalyst 1. Its XPS spectrum is as figure 1 shown.

Embodiment 2

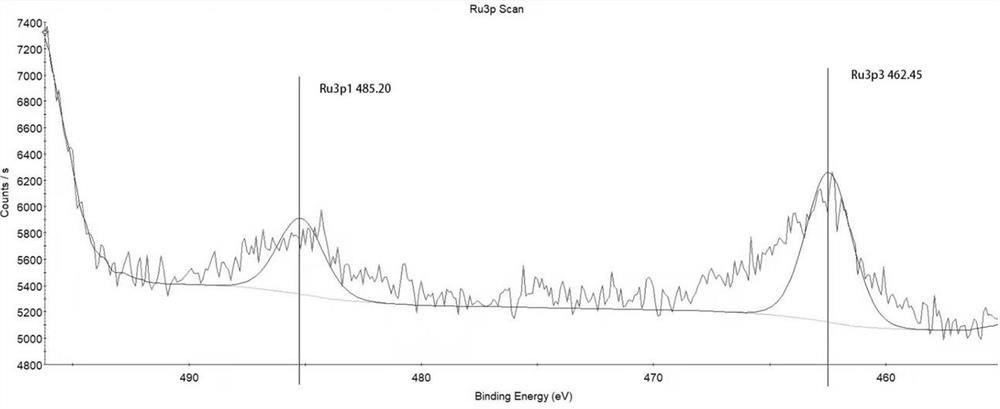

[0067] Add 15 mL of acetone and 0.1 g of ruthenium dodecacarbonyl triruthenium (0.33 mmol) into a 50 mL three-neck flask, dissolve and add 1.88 g of dry activated carbon, stir at 40°C under argon for 1 h, then remove under reduced pressure and collect the acetone , to obtain black powder carbonyl ruthenium carbon.

[0068] In another 50mL three-necked flask, add 15g of octadecylamine (0.056mol), 0.02g of iron-containing triiron dodecacarbonyl (0.12mmol) methanol solution (mass concentration 95%) and the aforementioned ruthenium carbonyl carbon, under argon Stir at 60°C for 1 hour to remove methanol, then raise the temperature to 130°C and keep it for 1 hour, and finally raise the temperature to 220°C and keep it for 0.5 hours. C Catalyst 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com