Heusler alloy Fe2CoAl/C self-supporting composite material for lithium electrode as well as preparation method and application of Heusler alloy Fe2CoAl/C self-supporting composite material

A composite material, lithium electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of high cost and complicated methods, and achieve the effect of avoiding uneven deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

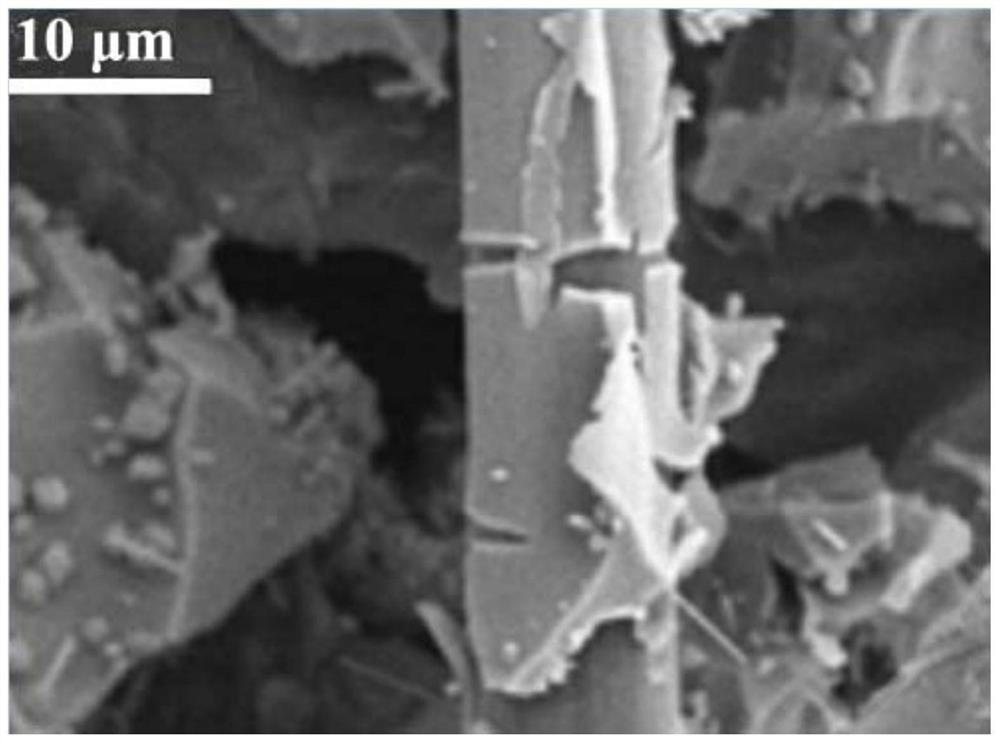

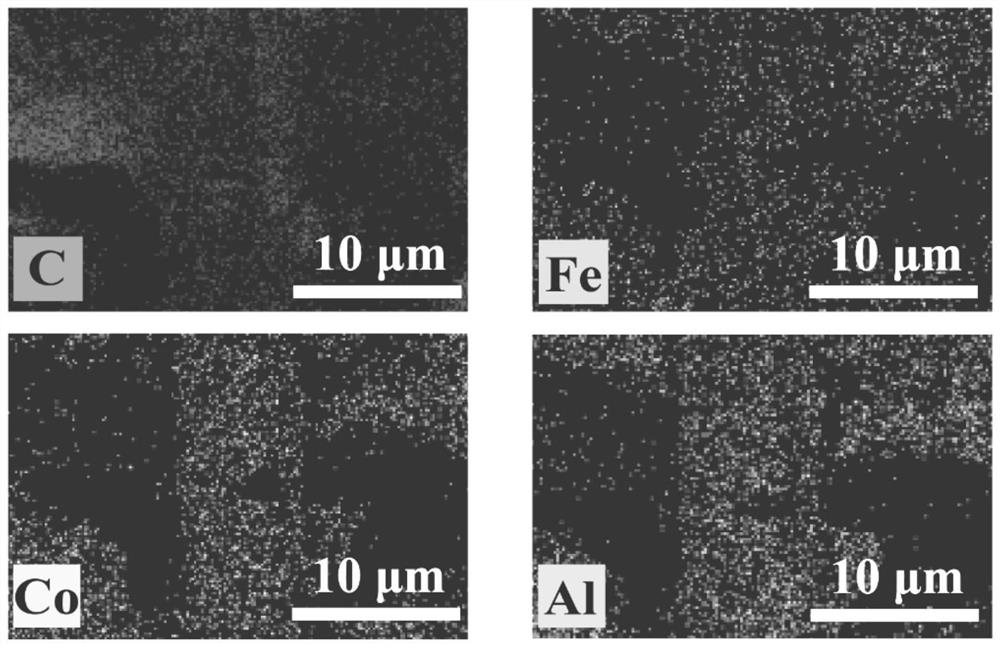

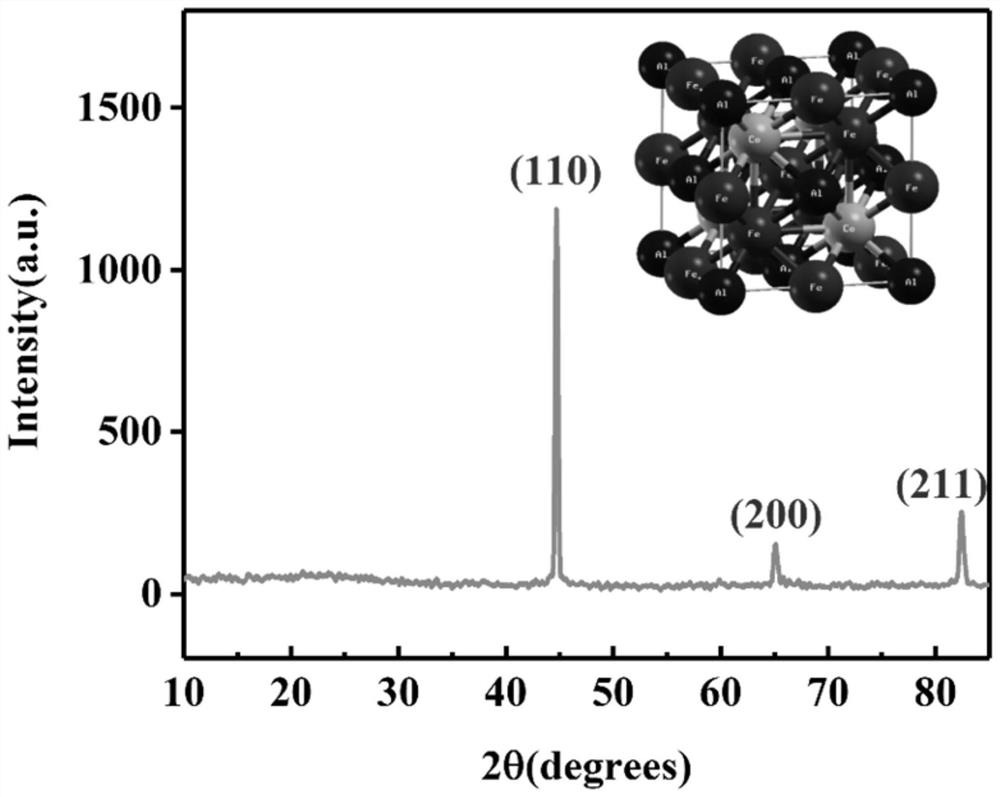

[0033] This embodiment provides a Heussler alloy Fe for lithium electrodes 2 The preparation method of CoAl / C self-supporting composite material specifically comprises the following steps:

[0034] Step 1: Dissolve 1.3129g of aluminum nitrate nonahydrate, 1.0185g of cobalt nitrate, and 2.8280g of ferric nitrate in 25ml of distilled water, and continue magnetic stirring for 3 hours to obtain a mixed solution;

[0035] Step 2: Weigh 2.22g of polyvinyl alcohol and add it to 20ml of distilled water, stir for 3 hours to obtain a polyvinyl alcohol solution with a mass concentration of 111g / L;

[0036] Step 3: Mix the two solutions obtained in Step 1 and Step 2 and continue to stir for 5 hours until they are evenly mixed, and then transfer the prepared mixed solution to a petri dish;

[0037] Step 4: Plasma treat the carbon paper for 10 minutes, soak the carbon paper in the mixed solution at room temperature for 2 minutes, put it in a 50°C oven and dry it for 15 minutes, and repeat ...

Embodiment 2

[0040] This embodiment provides a Heussler alloy Fe for lithium electrodes 2 The preparation method of CoAl / C self-supporting composite material specifically comprises the following steps:

[0041] Step 1: Dissolve 1.0667g of aluminum chloride, 1.0387g of cobalt chloride, and 2.5953g of ferric chloride in 40ml of distilled water, and continue magnetic stirring for 4 hours to obtain a mixed solution;

[0042] Step 2: Weigh 2 g of polyvinyl alcohol and add it to 50 ml of distilled water, stir for 3.5 hours to obtain a polyvinyl alcohol solution with a mass concentration of 40 g / L;

[0043] Step 3: Mix the two solutions obtained in Step 1 and Step 2 and continue to stir for 8 hours until they are evenly mixed, and then transfer the prepared mixed solution to a petri dish;

[0044] Step 4: Plasma treat the carbon paper for 12 minutes, soak the carbon paper in the mixed solution for 1 minute at room temperature, put it in a 30°C oven and dry it for 20 minutes, and repeat the opera...

Embodiment 3

[0047] This embodiment provides a Heussler alloy Fe for lithium electrodes 2 The preparation method of CoAl / C self-supporting composite material specifically comprises the following steps:

[0048] Step 1: Dissolve 0.8554g of aluminum sulfate, 1.4058g of cobalt sulfate, and 1.9993g of ferric sulfate in 25ml of distilled water, and continue magnetic stirring for 5 hours to obtain a mixed solution;

[0049] Step 2: Weigh 4 g of polyvinyl alcohol and add it to 30 ml of distilled water, stir for 5 hours to obtain a polyvinyl alcohol solution with a mass concentration of 133 g / L;

[0050] Step 3: Mix the two solutions obtained in Step 1 and Step 2 and continue to stir for 10 h until the mixture is uniform, and transfer the prepared mixed solution to a petri dish;

[0051] Step 4: Plasma treat the carbon paper for 15 minutes, soak the carbon paper in the mixed solution at room temperature for 5 minutes, put it in a 60°C oven and dry it for 10 minutes, and repeat the operation once;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com