Preparation and application of anode carbon-based membrane material for lithium-sulfur battery

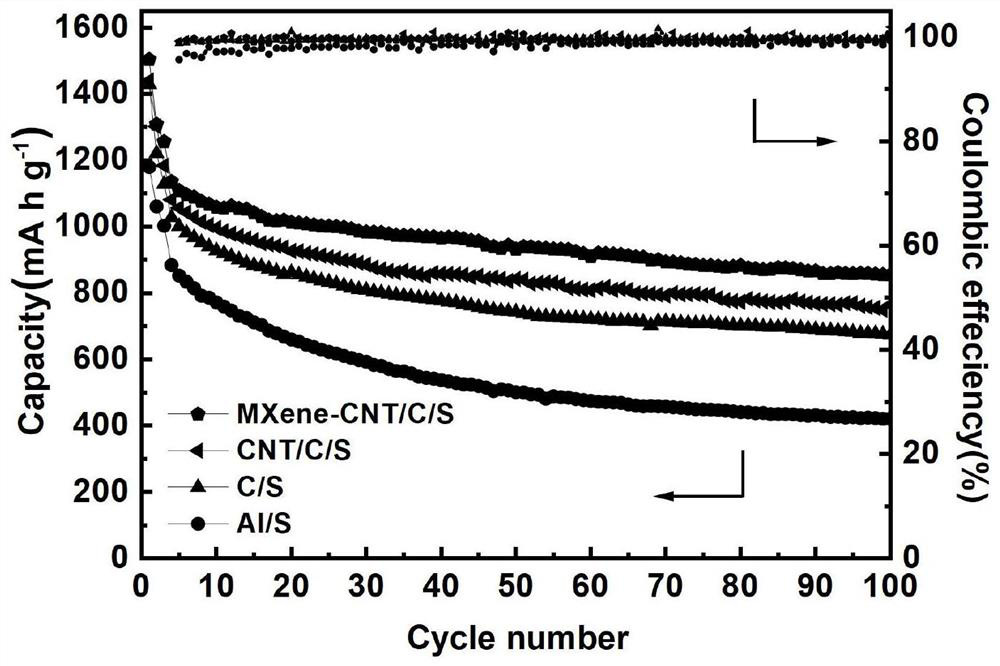

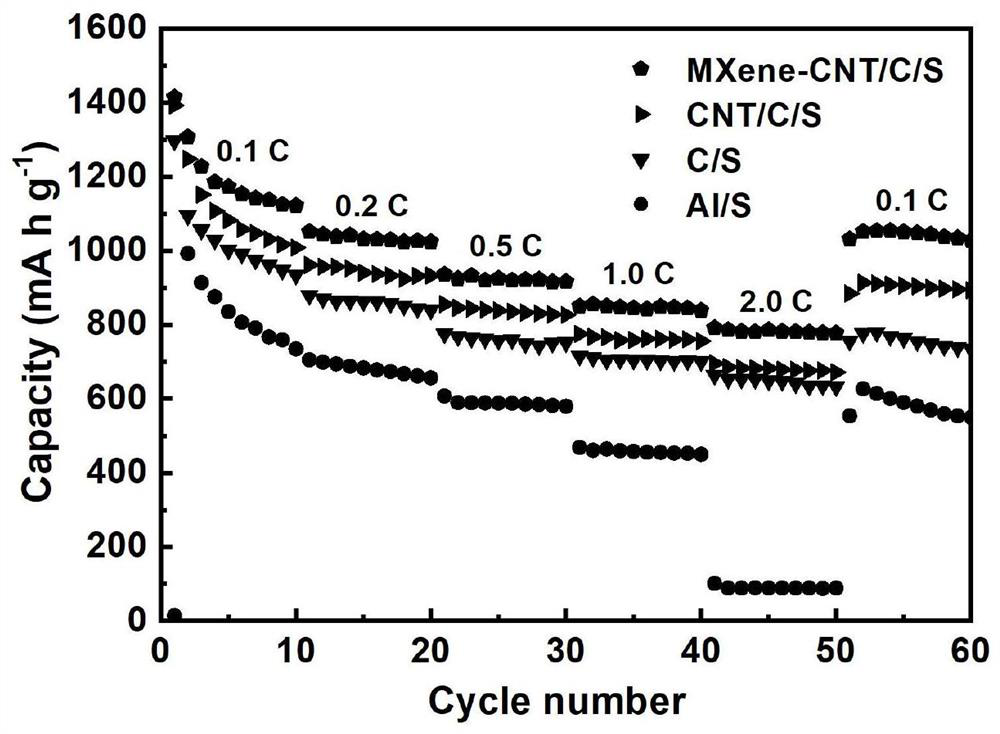

A lithium-sulfur battery and carbon-based film technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of capacity fading, low conductivity of elemental sulfur, unsatisfactory cycle life, etc., to improve charge and discharge capacity, suppress Shuttle effect, the effect of promoting the transfer of lithium ions and electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

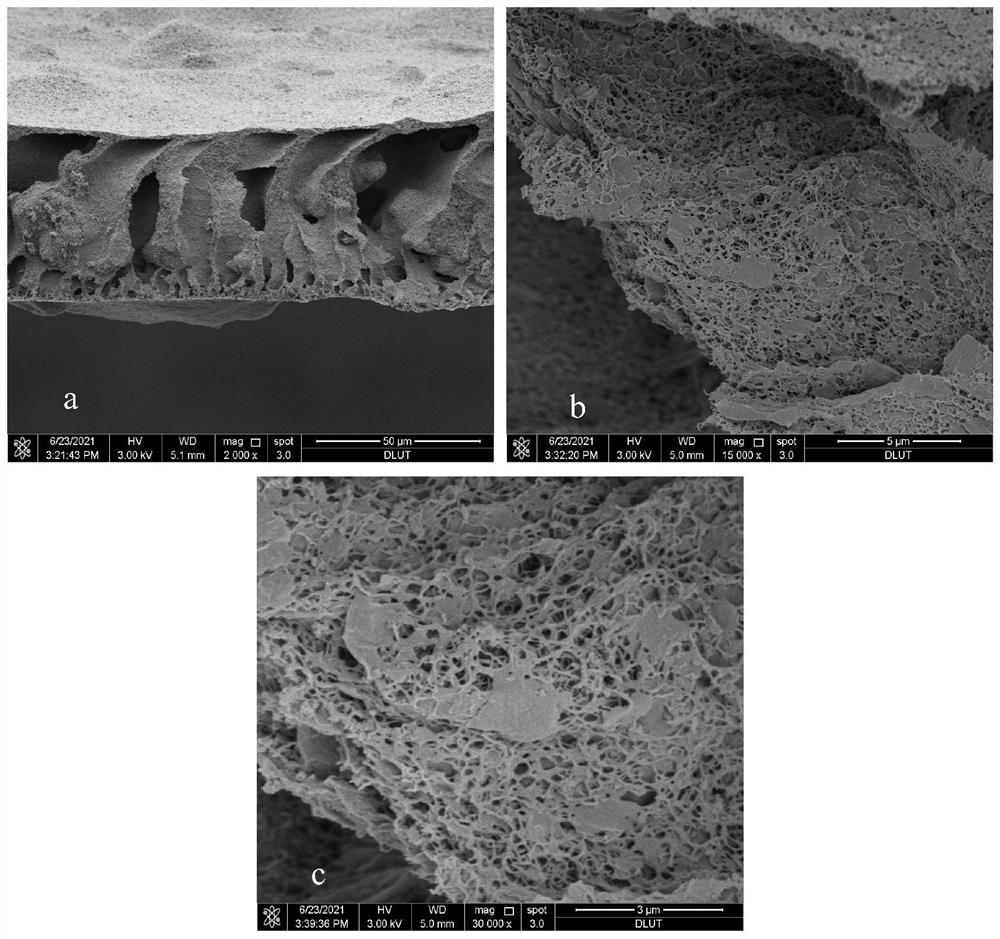

[0030] 1. Preparation of phase inversion MXene-CNT / C composite carbon-based membrane materials for lithium-sulfur batteries

[0031] 1) Add 20ml of 12M concentrated hydrochloric acid and 1.6g of lithium fluoride to the polytetrafluoroethylene reagent bottle, stir for 10 minutes, weigh 1.0g of titanium aluminum carbide powder and slowly add it to the reagent bottle, then magnetically stir the reagent bottle at 40°C After 40 hours, add water several times and centrifuge until the supernatant pH = 6, then collect the precipitate, then add deionized water to the precipitate, and sonicate for 2 hours under the protection of argon (ultrasonic power 240W), take the ultrasonic solution and centrifuge for 1 hour, collect The supernatant was freeze-dried for 3 days to obtain few-layer MXene;

[0032] 2) Add N,N-dimethylformamide, carbon nanotubes, few-layer MXene and polyacrylonitrile in sequence to a blue-capped silk-mouth bottle with a material mass ratio of 1:12:1:1. The silk bottle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap