Strontium titanate/bismuth molybdate heterojunction nanofiber photocatalyst as well as preparation method and application thereof

A nanofiber and photocatalyst technology, applied in the field of photocatalytic materials, achieves the effects of simple operation, no pollution to the environment, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

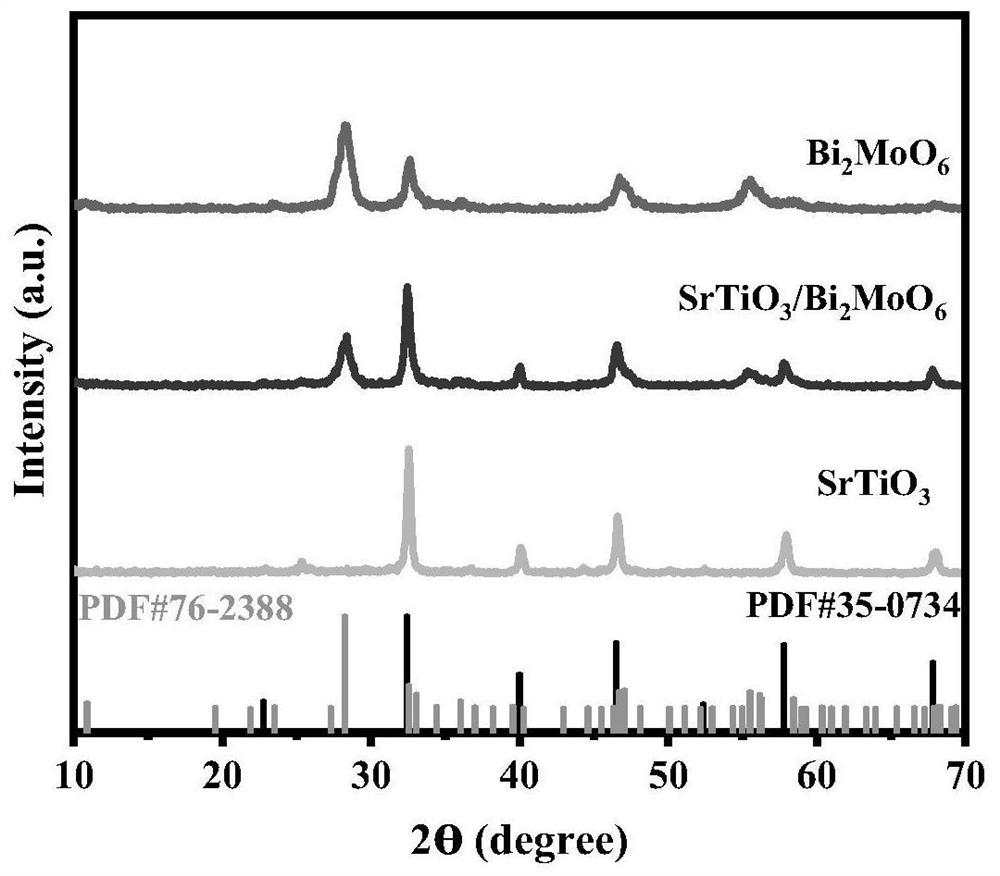

[0023] Embodiment 1 strontium titanate nanofiber photocatalyst

[0024] The preparation method is as follows

[0025] Mix 10mL DMF and 0.5mL nitric acid solution with a concentration of 65%, add 0.432g strontium carbonate and 1mL tetra-n-butyl titanate to the above mixed solution, and then add 0.8g PVP while stirring to obtain a precursor. Strontium carbonate / tetra-n-butyl titanate / PVP nanofibers are obtained by spinning;

[0026] Strontium carbonate / tetra-n-butyl titanate / PVP nanofibers were calcined under air conditions, the calcination temperature was 550°C, and the calcination time was 2 hours to obtain strontium titanate nanofiber photocatalysts, marked as SrTiO 3 .

Embodiment 2

[0027] Embodiment 2 bismuth molybdate nanosheet photocatalyst

[0028] The preparation method is as follows

[0029] Dissolve 0.1455g of bismuth nitrate pentahydrate and 0.036g of sodium molybdate into a mixed solution of 54mL of ethanol and 9mL of ethylene glycol, and use a hydrothermal method to prepare a bismuth molybdate nanosheet catalyst. The hydrothermal temperature is 160°C, and the hydrothermal time is 24h, the resulting photocatalyst was labeled as Bi 2 MoO 6 .

Embodiment 3

[0030] Example 3 Strontium titanate / bismuth molybdate heterojunction nanofiber photocatalyst

[0031] (1) The preparation method is as follows

[0032] Mix 10mL DMF and 0.5mL nitric acid solution with a concentration of 65%, add 0.432g strontium carbonate and 1mL tetra-n-butyl titanate to the above mixed solution, and then add 0.8g PVP while stirring to obtain a precursor. Strontium carbonate / tetra-n-butyl titanate / PVP nanofibers are obtained by spinning;

[0033] Calcining strontium carbonate / tetra-n-butyl titanate / PVP nanofibers under air conditions, the calcination temperature is 550°C, and the calcination time is 2 hours, to obtain strontium titanate nanofibers;

[0034] Dissolve 0.1455g of bismuth nitrate pentahydrate and 0.036g of sodium molybdate into a mixed solution of 54mL of ethanol and 9mL of ethylene glycol, then add 0.03g of strontium titanate nanofibers, and grow molybdenum on the surface of strontium titanate nanofibers by hydrothermal method The strontium ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com