Method for manufacturing conductive pattern by selectively activating insulating material by using laser

An insulating material and selective technology, applied in manufacturing tools, laser welding equipment, printed circuit manufacturing, etc., can solve the problems of high cost of substrates, heavy environmental burden, and changes, and achieve high pass rate and less overflow plating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The material of this example is an ordinary grade ABS plastic board, and the ABS material is a polymer of three monomers of acrylonitrile (Acrylonitrile), 1,3-butadiene (Butadiene), and styrene (Styrene).

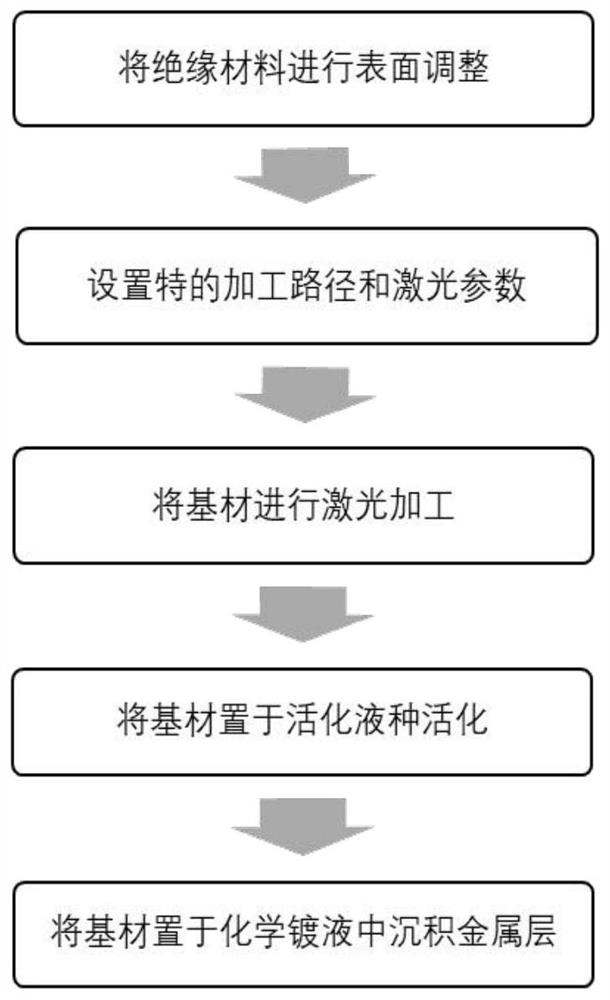

[0076] (1) Surface adjustment of the ABS base material.

[0077] The surface adjustment treatment process is preferably plasma treatment, the gas ratio is preferably: nitrogen / oxygen / carbon tetrafluoride = 1 / 8 / 2, the temperature is 30-70 degrees Celsius, and the treatment time is 1-3 minutes. The hydrophilicity of the treated ABS substrate increases, but the adsorption of colloidal palladium is weakened.

[0078] (2) Set the processing path and laser parameters.

[0079] In this embodiment, the DirectLaser 600P ultraviolet picosecond laser machine produced by Dezhong (Tianjin) Technology Development Co., Ltd. is preferably used to carry out the laser processing test. The power is preferably 40-90%. The corresponding pit diameters after single pulse or pulse train p...

Embodiment 2

[0097] The material of this example uses PC (40%)+ABS plastic alloy.

[0098] (1) Coat the PC (40%)+ABS material surface with a coating.

[0099] The type of coating is preferably silicone resin, and the solid content of the prepared solution is 2%-6%. Coating by dipping, time 3-10s, room temperature.

[0100] Use Dyne to test surface tension. The surface tension of the material was 36 before coating and dropped to 32 after coating. Observation and comparison under a microscope shows that there are micropits invisible to the naked eye on the surface of the substrate before coating, and the micropits are filled after coating.

[0101] (2) Set the processing path and laser parameters.

[0102] In this embodiment, the DirectLaser U5 ultraviolet nanosecond laser machine produced by Dezhong (Tianjin) Technology Development Co., Ltd. is preferably used for laser processing. This device has a zoom beam expander system.

[0103] The initial beam expansion factor is 3 times, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com