Temperature-resistant, acid-resistant and salt-resistant acid liquid thickening agent and preparation method thereof

An acid thickener, temperature-resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as fast reaction speed, poor acid stability and temperature resistance, mud sand and emulsion blockage, etc. Achieve good solubility and acid resistance, improve shear resistance, and enhance thickening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method of temperature-resistant, acid-resistant and salt-resistant type acid liquid thickener in the first aspect, described method comprises the following steps:

[0027] (1) Dissolving non-ionic water-soluble monomers and cationic monomers in water to obtain a first mixed solution; in the present invention, the water is preferably deionized water; in some specific embodiments, the step (1 ) For example: at room temperature (for example, room temperature 20~30°C), add the non-ionic water-soluble monomer and cationic monomer into deionized water respectively, and then stir for 15 minutes at a speed of 300r / min until the non-ionic water-soluble The monomer and the cationic monomer are all dissolved in deionized water to obtain the first mixed solution.

[0028] (2) Dissolving the salt-resistant monomer, temperature-resistant monomer, hydrophobic monomer, penetrant and co-solvent in the first mixed liquid to obtain the ...

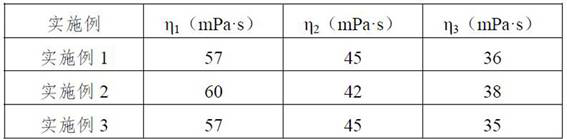

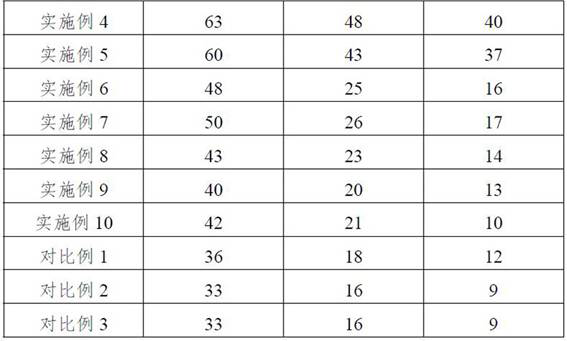

Embodiment 1

[0051] The raw materials for preparing the temperature-resistant, acid-resistant and salt-resistant type acid thickener are:

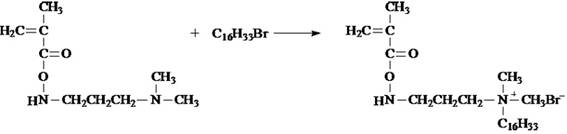

[0052] Non-ionic water-soluble monomer acrylamide 150g, cationic monomer acryloyloxyethyltrimethylammonium chloride 200g, salt-resistant monomer tert-butylacrylamidesulfonic acid 1.09g, salt-resistant monomer 6-amino-5- Bromopyridine-3-sodium sulfonate 0.66g, temperature-resistant monomer vinylbenzenesulfonic acid 0.58g, temperature-resistant monomer 4,4'-dihydrazinostilbene-2,2'-disulfonic acid 0.12g, Hydrophobic monomer butyl acrylate 1.17g, hydrophobic monomer methacryloxyethyl dimethyl n-hexadecyl ammonium bromide 2.33g, penetrant isooctyl alcohol polyoxyethylene ether (JC-3) 1.05g, Chain extender polyethylene glycol diacrylate (polyethylene glycol diacrylate with an average molecular weight of 400) 0.035g, co-solvent nonylphenol polyoxyethylene ether (nonylphenol polyoxyethylene ether TX-10) 3.5g, azo initiator azobisisobutylamidine hydrochloride...

Embodiment 2

[0060] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0061] The nonionic water-soluble monomer is 150 g of N-methylolacrylamide, and the cationic monomer methacryloyloxyethyltrimethylammonium chloride is 200 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com