Copper-tungsten disulfide self-lubricating composite material with layered structure, preparation method and application

A technology of tungsten disulfide and layered structure, which is applied in the direction of lubricating composition, base material, petroleum industry, etc., and can solve the problems of small area and low orientation of the layered structure area of porous BN scaffolds and composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

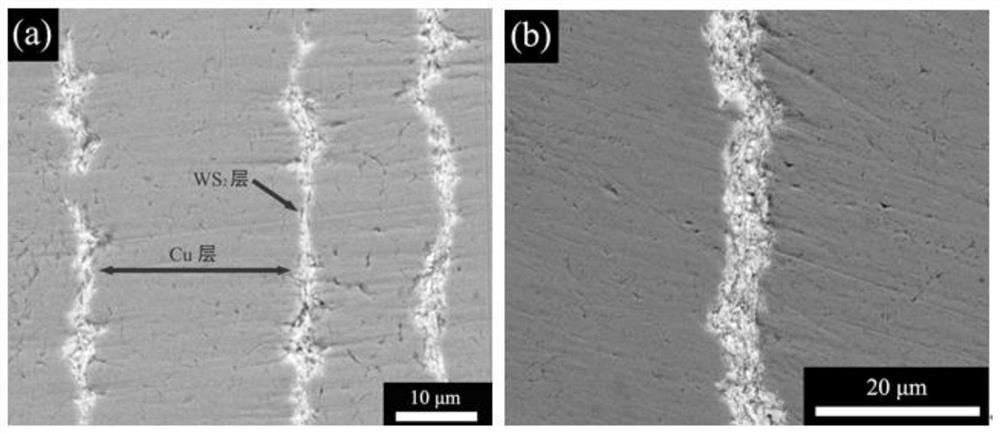

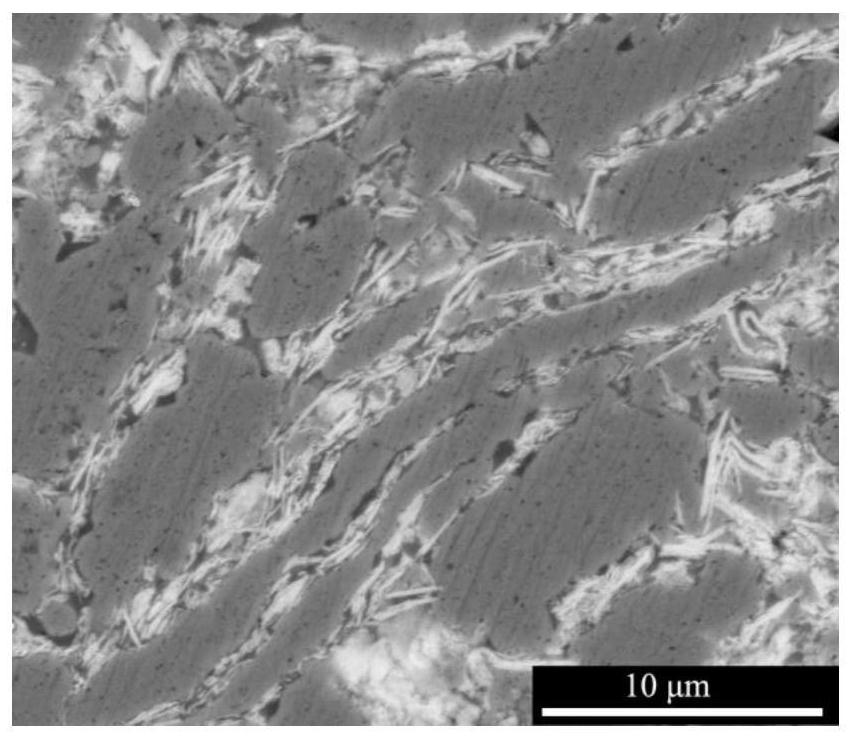

[0038] Add 24.4g WS to the mixing tank 2 Powder (average particle size is 5.0μm), 100g deionized water and 2.0g gelatin, after ball milling and mixing for 20h (ball milling speed: 100rpm, mass ratio of ball to material is 2:1) to obtain stable WS 2 Water-based slurry; pour the water-based slurry into a freezing mold containing a wedge-shaped mold, and then put it into a directional temperature field (the temperature at the bottom end is set to -30°C, and the temperature at the top end is 5°C) for directional solidification. The samples were placed in a vacuum freeze dryer for deicing. The dried green material is cut into 12×35×24mm 3 The cuboid was infiltrated into the organic copper paste with a mass fraction of 60% by the vacuum pressure method, and the porous WS infiltrated with the copper paste was infiltrated. 2 The green material was put into a hydrogen furnace for organic removal and copper powder reduction, and heated to 400°C at a heating rate of 5°C / min for 2 hours...

Embodiment 2

[0040] Add 15.5g WS to the mixing tank 2 Powder (average particle size is 5.0μm), 100g deionized water and 2.0g chitosan, after ball milling and mixing for 20h (ball milling speed: 100rpm, mass ratio of ball to material: 2:1) to obtain WS with stable performance 2 Water-based slurry; pour the slurry into a freezing mold containing a wedge-shaped mold, and then put it into a directional temperature field (the temperature at the bottom end is set to -40°C, and the temperature at the top end is 5°C) for directional solidification, and the obtained sample is placed in De-icing was carried out in a vacuum freeze dryer. The dried green material is cut into 12×35×24mm 3 The cuboid was infiltrated into the organic copper-tin alloy slurry with a mass fraction of 50% (tin content 10.0%) by the vacuum pressure method, and the porous WS infiltrated with copper-tin particles was infiltrated. 2 The green body material is put into a hydrogen furnace for organic removal and copper powder re...

Embodiment 3

[0042] Add 24.4g WS to the mixing tank 2 Powder (average particle size is 5.0μm), 100g deionized water and 2.0g polyvinyl alcohol, after ball milling for 20h (ball milling speed: 100rpm, mass ratio of balls: 2:1) to obtain stable WS 2 Water-based slurry; pour the slurry into a freezing mold containing a wedge-shaped mold, and then put it into a directional temperature field (the temperature at the bottom end is set to -30°C and the temperature at the top end is 5°C) for directional solidification, and the obtained sample is placed De-icing was carried out in a vacuum freeze dryer. The dried green material is cut into 12×35×24mm 3 The cuboid was infiltrated into the organic copper-nickel alloy slurry with a mass fraction of 70.0% (the nickel content was 15.0%) by the vacuum pressure method, and the porous WS infiltrated with copper-nickel particles was infiltrated. 2 The green material is put into a hydrogen furnace for organic removal and copper powder reduction, and heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com