Hollow porous carbon nanofiber with tin oxide loaded on inner tube wall as well as preparation method and application of hollow porous carbon nanofiber

A technology of nanofibers and tin oxide, applied in the manufacture of hollow filaments, fiber chemical characteristics, negative electrodes, etc., can solve the problems of easy expansion of tin oxide, unstable interface, hindering practical application, etc. The effect of life and service efficiency, enhanced adsorption and storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

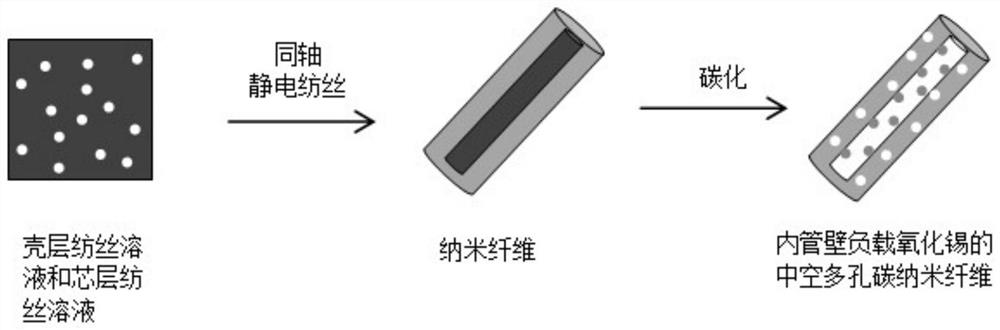

[0041] Such as figure 1As shown, the preparation method of the hollow porous carbon nanofibers with tin oxide on the inner wall of the present embodiment comprises the following steps:

[0042] (1) Mix 1.4g polyacrylonitrile (PAN), 0.5g polymethylmethacrylate (PMMA) and 0.2g polyvinylpyrrolidone (PVP) and add them to 17.6g of N,N-dimethylformamide , stirred for 6h and ultrasonically treated for 4h to prepare the shell spinning solution.

[0043] (2), 2.2g polyvinylpyrrolidone and 0.2g stannous chloride dihydrate (SnCl 2 2H 2 O) After mixing, add 1 g of ethanol and 17.6 g of N,N-dimethylformamide into a mixed solvent, stir for 6 h and ultrasonically treat for 4 h to prepare a core layer spinning solution.

[0044] (3) The prepared shell spinning solution and the core spinning solution were respectively injected into a 5mL syringe with a coaxial needle of 16G / 21G, and coaxial electrospinning was carried out at a spinning voltage of 20kV to obtain carbon fibers Precursor; whe...

Embodiment 2

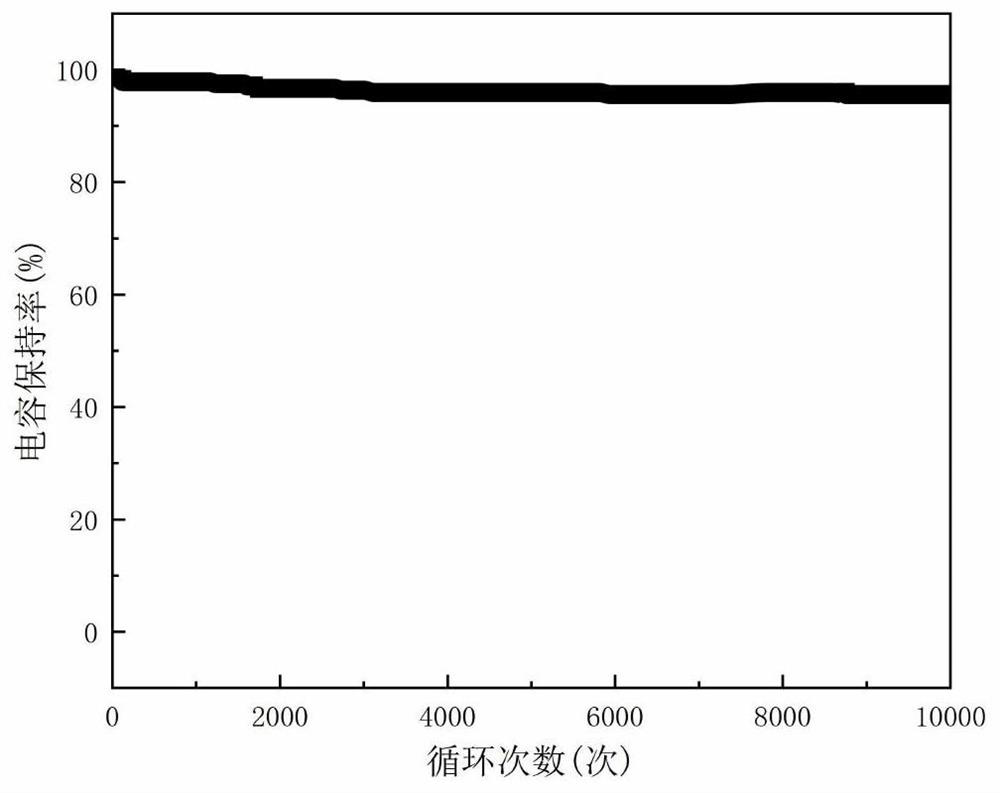

[0048] The amount of stannous chloride dihydrate in Example 1 was changed to 0.1 g, and the rest were the same as in Example 1, and the finally obtained material was denoted as HPCNF-2. The content of tin oxide in the pores of this component material is less and unevenly distributed, so the effect of tin oxide is less obvious, and the specific surface area is 25cm 2 / g, the specific capacitance is 1237.5F / g at a current density of 1A / g. This electrode material is assembled into a supercapacitor, such as image 3 As shown, after 10,000 charge-discharge cycles, the stability is better, reaching 90.6%.

Embodiment 3

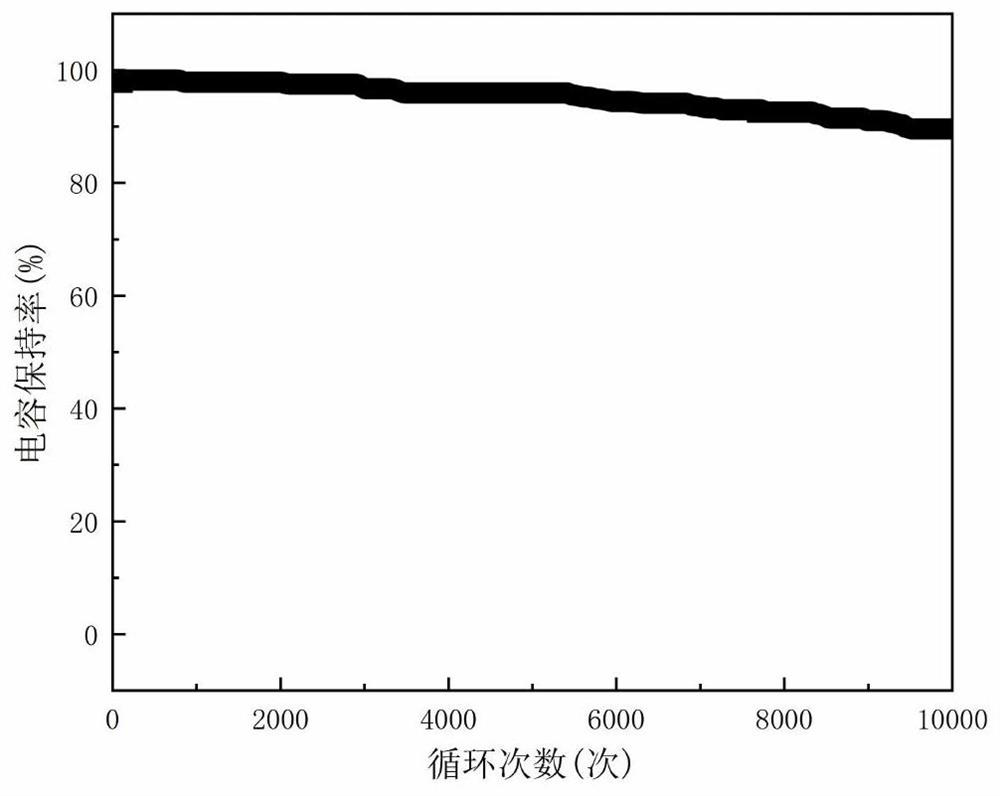

[0050] The amount of stannous chloride dihydrate in Example 1 was changed to 0.3g, all the others were the same as in Example 1, and the finally obtained material was denoted as HPCNF-3. There are more tin oxide distributed in the fiber hollow channel of this component material, but less effectively adheres to the tube wall, causing certain blockage to the hollow channel, and the specific surface area is 19.6cm 2 / g, the specific capacitance is 1024.2F / g at a current density of 1A / g. This electrode material is assembled into a supercapacitor, such as Figure 4 As shown, after 10,000 charge-discharge cycles, the stability is good at 88.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com