Whitening and spot-fading compound preparation with fructus phyllanthi fresh fruit pulp as main raw material and preparation method of whitening and spot-fading compound preparation

A technology of olive fresh fruit and compound preparation, applied in the field of whitening and lightening skin care, can solve the problems of reducing the intrinsic quality and function of Yunnan olive products, destroying nutrients and active ingredients, and complex extraction process, achieving better effect and simple preparation process. , the effect of improving economic benefits and comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of skin care lotion with Yunnan olive fresh fruit pulp as main raw material and its preparation method, through the following steps:

[0046](1) Raw materials are prepared according to the following mass percentages: 10% green thorn fruit oil, 70.7% Yunnan olive fresh fruit pulp, 0.2% sodium hyaluronate, 4% glycerin, 1% cetyl alcohol, 1% stearyl alcohol, wool 0.5% butter, 0.5% stearic acid, 3% butylene glycol, 4% 1,2-pentanediol, 1.5% glyceryl monostearate, 1% polydimethylsiloxane, poloxamer 188 1.5%, xanthan gum 0.3%, triethanolamine 0.5%, phenoxyethanol 0.3%;

[0047] (2) Take green thorn fruit oil, cetyl alcohol, stearyl alcohol, stearic acid, lanolin, polydimethylsiloxane, glyceryl monostearate, poloxamer 188 and add them to the oil phase pot, Heat to 70°C, stir evenly to make it fully melted and mixed;

[0048] (3) Add glycerin, butylene glycol, xanthan gum, sodium hyaluronate, and Yunnan olive fresh fruit pulp into the water phase pot, heat to 70°C, stir ...

Embodiment 2

[0056] A kind of skin care lotion with Yunnan olive fresh fruit pulp as main raw material and its preparation method, through the following steps:

[0057] (1) Raw materials are prepared according to the following mass percentages: green thorn fruit oil 8%, Yunnan olive fresh fruit pulp pulp 70.7%, sodium hyaluronate 0.3%, glycerin 4%, cetyl alcohol 2%, stearyl alcohol 2%, wool 0.5% butter, 0.5% stearic acid, 3% butylene glycol, 4% 1,2-pentanediol, 1.5% glyceryl monostearate, 1% polydimethylsiloxane, poloxamer 188 1.5%, xanthan gum 0.2%, triethanolamine 0.5%, phenoxyethanol 0.3%;

[0058] (2) Take green thorn fruit oil, cetyl alcohol, stearyl alcohol, stearic acid, lanolin, polydimethylsiloxane, glyceryl monostearate, poloxamer 188 and add them to the oil phase pot, Heat to 70°C, stir evenly to make it fully melted and mixed;

[0059] (3) Add glycerin, butylene glycol, xanthan gum, sodium hyaluronate, and Yunnan olive fresh fruit pulp into the water phase pot, heat to 70°C, ...

Embodiment 3

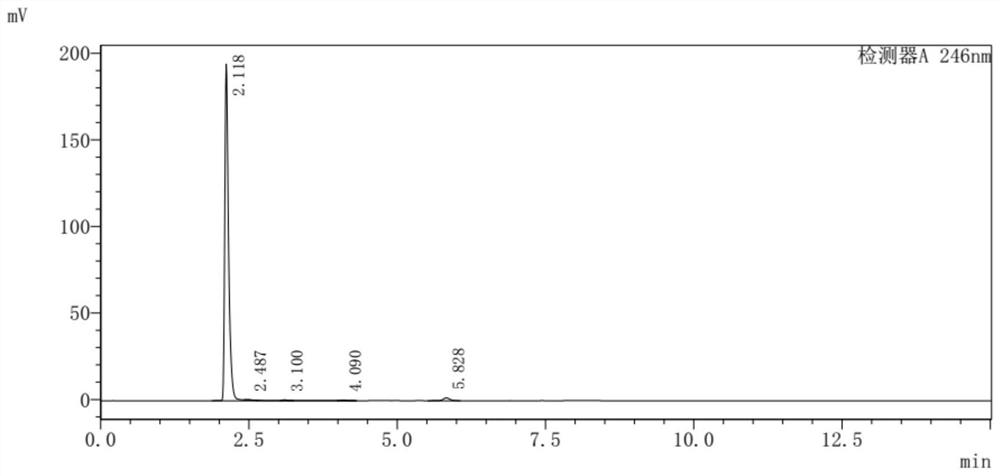

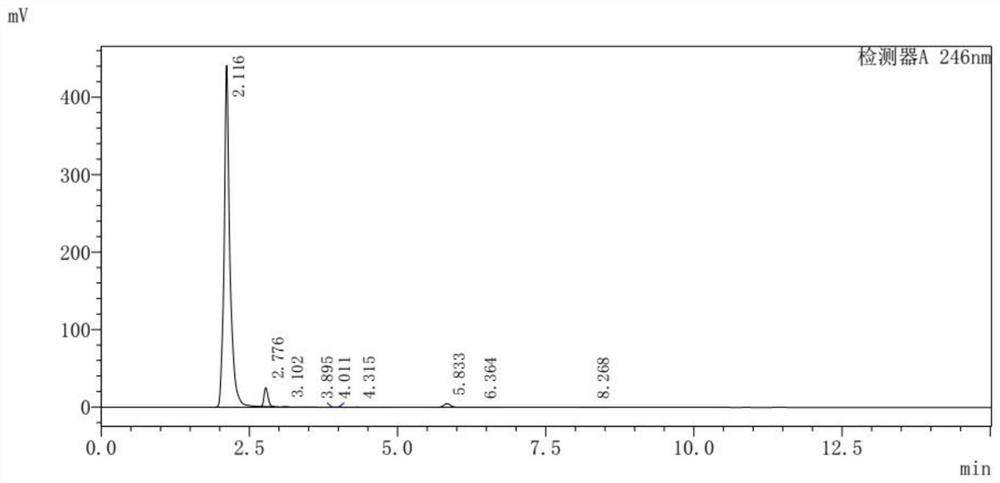

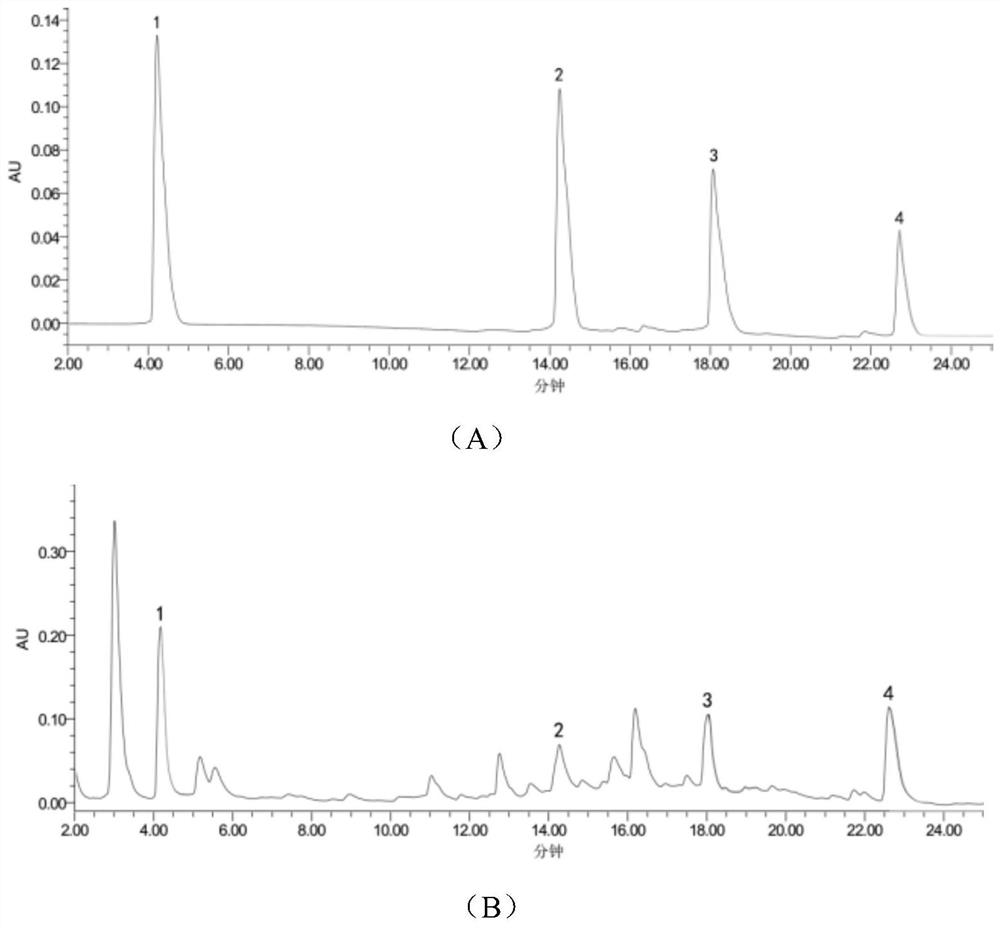

[0067] Determination of vitamin C content in emulsion by HPLC method:

[0068] Preparation of reference solution:

[0069] Accurately weigh 0.0041g of vitamin C reference substance (Beijing Zhongke Quality Inspection Biological Co., Ltd.) (50-81-7) (purity ≥ 98%), add acetonitrile-water (2:1) mixed solution to make up to 100mL capacity in the bottle.

[0070] The concentration of the reference solution is: Preparation of sample solution:

[0071] Accurately weigh 2g of the emulsion, place it in a 250mL Erlenmeyer flask, accurately add 50mL of acetonitrile-water (2:1) mixed solution, weigh the weight, ultrasonicate for 30min, weigh again, and use acetonitrile-water (2:1) The mixed solution made up for weight loss, shaken up, filtered, and the filtrate was taken.

[0072] test methods:

[0073] Chromatographic conditions: octadecylsilane bonded silica gel as filler; acetonitrile-0.01mol / L potassium dihydrogen phosphate aqueous solution (80:20) as mobile phase; detection wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com