Porous sodium alginate nanofiber scaffold material and preparation method thereof

A sodium alginate and nanofiber technology, applied in fiber treatment, fiber chemical characteristics, pharmaceutical formulations, etc., can solve problems such as unfavorable cell growth and transfer, unfavorable gas and nutrient transport, etc., and achieve stable preparation process and good affinity. Water effect, strong water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

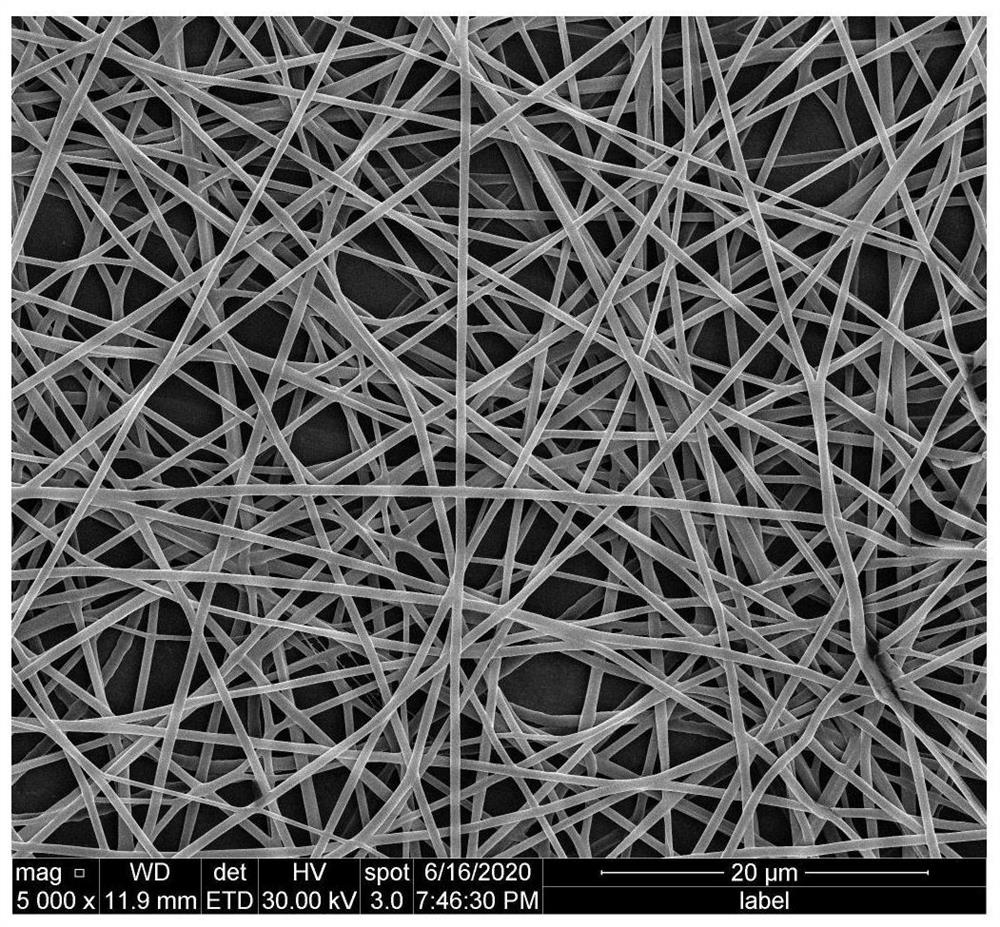

[0028] A kind of preparation method of porous sodium alginate nanofiber support, specifically is carried out according to the following steps:

[0029] (1) Sequentially weigh 0.32g of sodium alginate powder and 1.28g of PVA powder and add them to 20ml of deionized water, and magnetically stir in a water bath at 60°C for 6 hours to completely dissolve sodium alginate and PVA to form a transparent spinning solution .

[0030] (2) Place the above spinning solution in the needle tube of the electrospinning device, adjust the voltage to 25kV, the distance from the nozzle to the receiver is 15cm, and the flow rate is 1.5ml / h. The sodium alginate composite nanofiber membrane prepared by electrospinning was dried in a constant temperature drying oven for 48 hours.

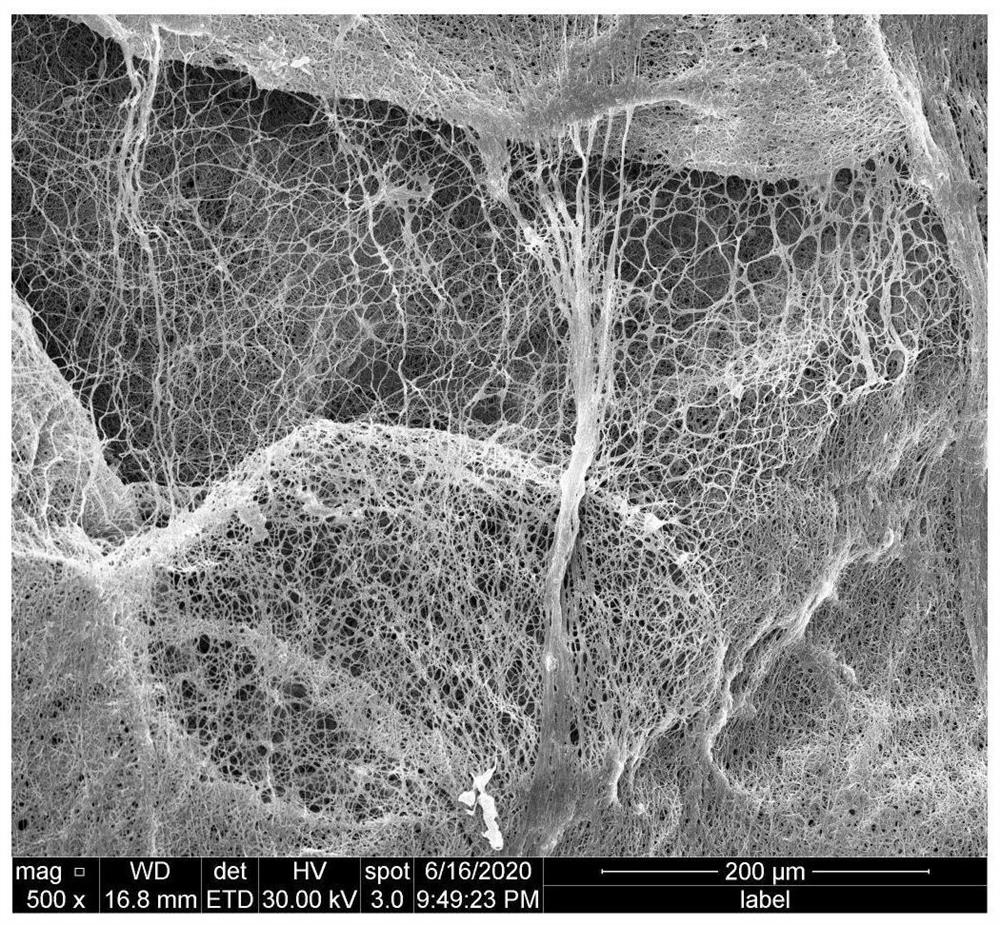

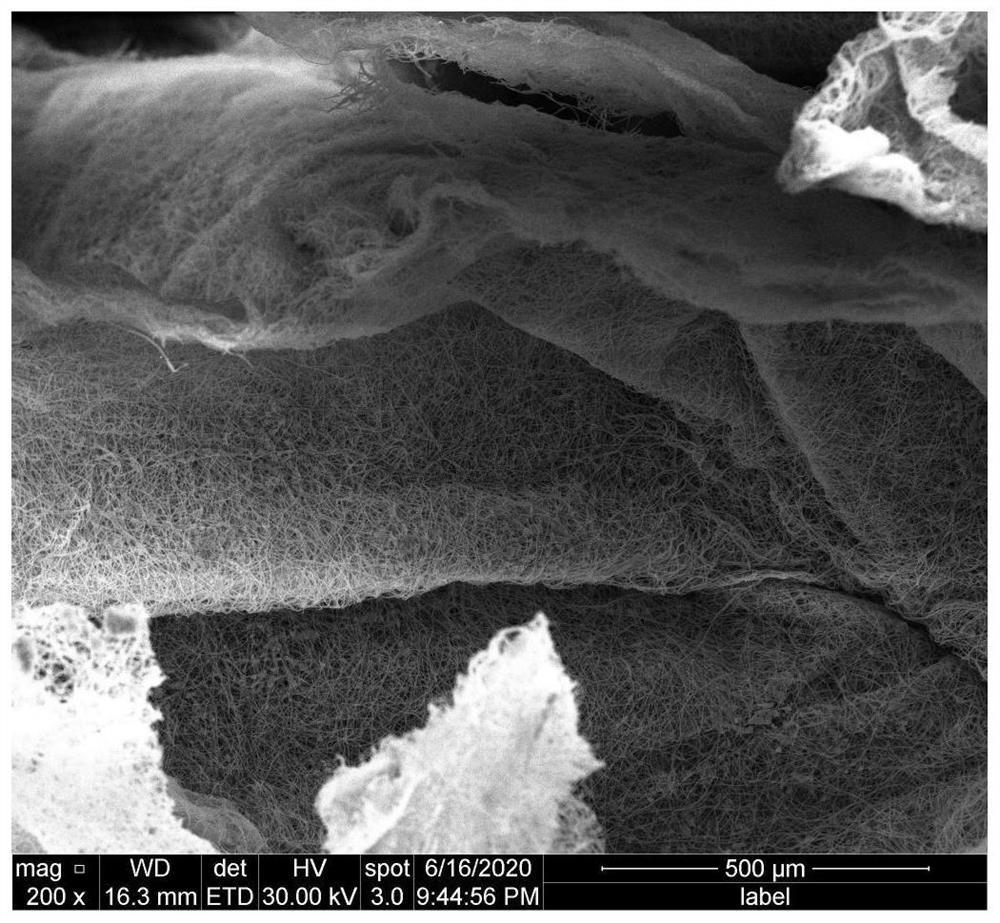

[0031] (3) The above-mentioned sodium alginate composite nanofiber membrane was placed in a 0.2M concentration of sodium borohydride methanol solution for foaming for 12 hours, after taking it out, it was repeatedly rinse...

Embodiment 2

[0034] A kind of preparation method of porous sodium alginate nanofiber support, specifically is carried out according to the following steps:

[0035] (1) Sequentially weigh 0.48g of sodium alginate powder and 1.12g of PVA powder and add them to 20ml of deionized water, and magnetically stir in a water bath at 60°C for 6 hours to completely dissolve sodium alginate and PVA to form a transparent spinning solution .

[0036] (2) The above spinning solution was placed in the needle tube of the electrospinning device, the voltage was adjusted to 27kV, the distance from the nozzle to the receiver was 17cm, and the flow rate was 1.2ml / h. The sodium alginate composite nanofiber membrane prepared by electrospinning was dried in a constant temperature drying oven for 48 hours.

[0037] (3) The above-mentioned sodium alginate composite nanofiber membrane was placed in a 0.3M sodium borohydride methanol solution for foaming for 12 hours, and after taking it out, it was repeatedly rinse...

Embodiment 3

[0040] A kind of preparation method of porous sodium alginate nanofiber support, specifically is carried out according to the following steps:

[0041] (1) Sequentially weigh 0.16g of sodium alginate powder and 1.44g of PVA powder and add them to 20ml of deionized water, and magnetically stir in a water bath at 60°C for 6 hours to completely dissolve sodium alginate and PVA to form a transparent spinning solution .

[0042] (2) The above spinning solution was placed in the needle tube of the electrospinning device, the voltage was adjusted to 19kV, the distance from the nozzle to the receiver was 15cm, and the flow rate was 1.5ml / h. The sodium alginate composite nanofiber membrane prepared by electrospinning was dried in a constant temperature drying oven for 48 hours.

[0043] (3) The above-mentioned sodium alginate composite nanofiber membrane was placed in a 0.5M concentration of sodium borohydride methanol solution for foaming for 12 hours, after taking it out, it was rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com