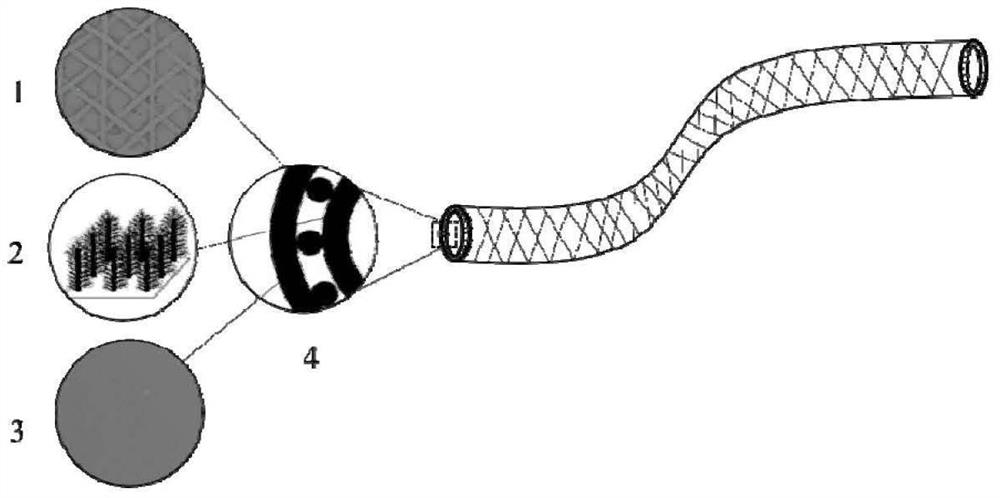

A long-acting antibacterial and anti-stenosis functional urethral stent and its preparation method

An anti-stenosis and functional technology, applied in other medical devices, dilators, surgery, etc., can solve the problems of poor antibacterial and anti-stenosis effects, and achieve the effects of inhibiting overgrowth, increasing the specific surface area of the lumen, and inhibiting the formation of stenosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

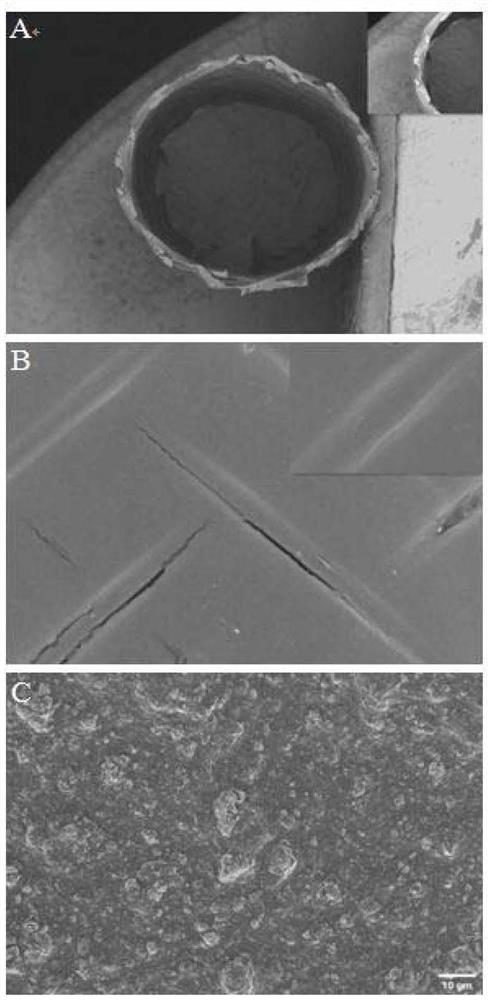

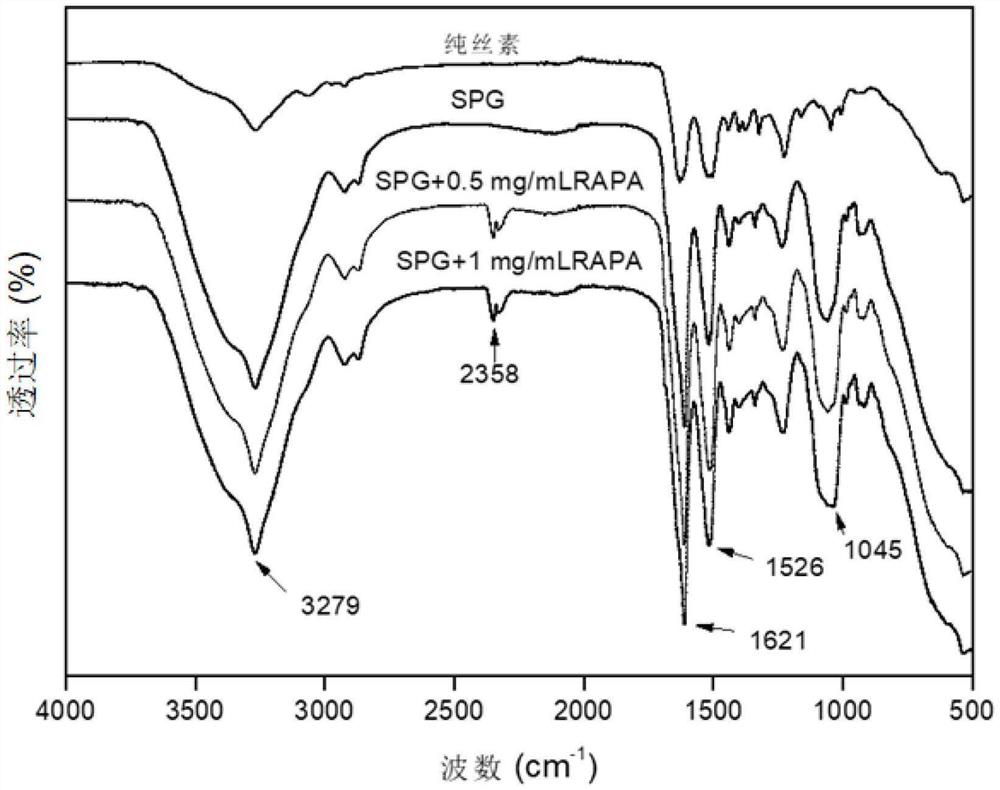

[0073] A preparation method of a long-acting antibacterial and anti-stenosis functional urethral stent, the specific steps are as follows:

[0074] (1) prepare a fabric tube;

[0075]The yarn is made into a fabric tube by a textile forming method, wherein the yarn is composed of a plurality of silk filaments with a fineness of 7tex and a medical magnesium wire with a developing function with a fineness of 7tex; It is an 8-spindle automatic braiding machine, the braiding structure adopts diamond braiding (1 / 1 interweaving), the braiding speed is 40rpm, the gear ratio is 82 / 21, and the braiding height is 25cm;

[0076] The prepared fabric tube is a tubular fabric, the radial compression modulus of the fabric tube is 0.03MPa, the elastic recovery rate is 74.68%, the circumferential expansion breaking strength is 0.03MPa, and the yarn coverage is 67.11%;

[0077] (2) Preprocessing;

[0078] Under the condition of temperature of 50°C, the fabric tube obtained in step (1) was wash...

Embodiment 2

[0098] A preparation method of a long-acting antibacterial and anti-stenosis functional urethral stent, the specific steps are as follows:

[0099] (1) prepare a fabric tube;

[0100] The yarn is made into a fabric tube by a textile forming method, wherein the yarn is composed of a plurality of polylactic acid filaments with a fineness of 20 tex and a medical tantalum wire with a developing function with a fineness of 20 tex; The knitted structure adopts weft knitted single jersey;

[0101] The prepared fabric tube is a tubular fabric, the transverse coil density is 25 wales / 5cm, the longitudinal coil density is 25 courses / 5cm, the coil length is 5mm, and the total density is 2000 coils / 25cm 2 ; The radial compression modulus of the fabric tube is 1.31MPa, the elastic recovery rate is 87.14%, the circumferential expansion breaking strength is 4.88MPa, and the yarn coverage rate is 75.32%.

[0102] (2) Preprocessing;

[0103] The fabric tube obtained in step (1) was washed w...

Embodiment 3

[0125] A preparation method of a long-acting antibacterial and anti-stenosis functional urethral stent, the specific steps are as follows:

[0126] (1) prepare a fabric tube;

[0127] The yarn is made into a fabric tube by a textile forming method, wherein the yarn is composed of a plurality of polydioxanone filaments with a fineness of 40tex and a medical silver wire with a development function of a fineness of 40tex; Forming adopts weaving process, and weaving structure adopts plain weave;

[0128] The prepared fabric tube is a tubular fabric, the warp density is 100 pieces / 10 cm, and the weft density is 100 pieces / 10 cm; the radial compression modulus of the fabric tube is 2.11MPa, the elastic recovery rate is 81.57%, and the circumferential expansion is The breaking strength is 5.79MPa, and the yarn coverage is 66.67%;

[0129] (2) Preprocessing;

[0130] The fabric tube obtained in step (1) was washed with oxalic acid solution with a concentration of 4 wt % for 40 min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com