Method for preparing macroporous aerogel by using high-internal-phase Pickering emulsion as template and application of macroporous aerogel

A technology with high internal phase and airgel, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as poor adsorption effect and low dye removal rate, and achieve enhanced stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of high internal phase Pickering emulsion, its preparation method specifically comprises:

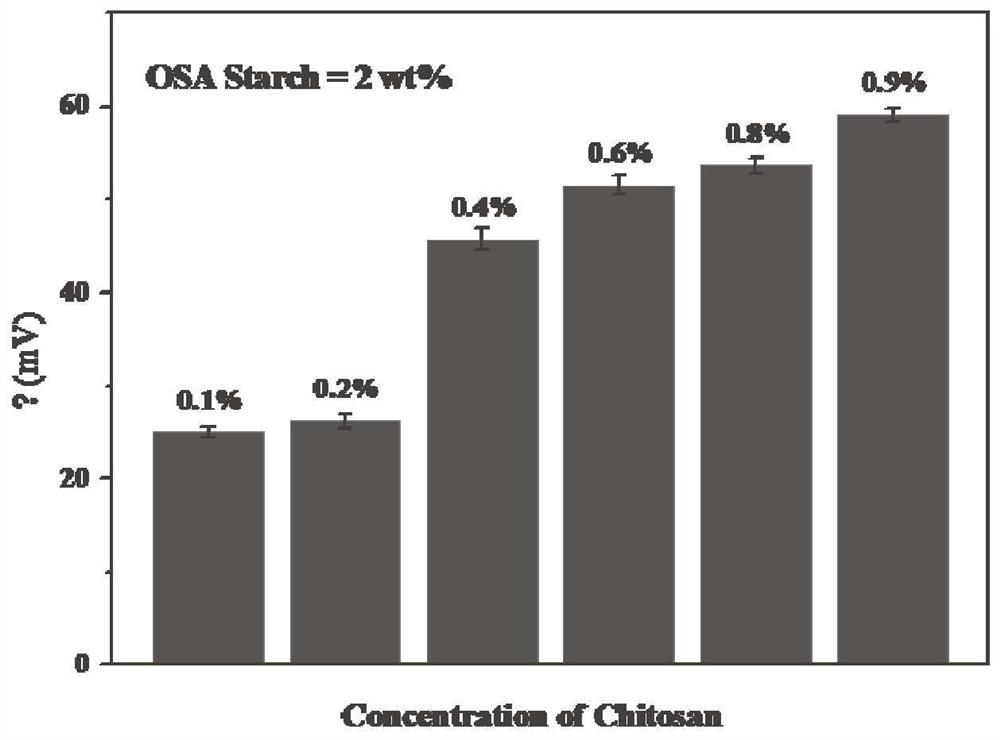

[0058] A typical sample preparation procedure is as follows. Dissolve 1g glacial acetic acid in 100g water, obtain mass fraction and be 1% acetic acid aqueous solution, dissolve 1g chitosan in the 1% acetic acid aqueous solution of 50g, can obtain chitosan mass fraction be 2%, glacial acetic acid mass fraction is 1% aqueous solution. Dissolve 5g of OSA starch in 50g of water to obtain a 10% OSA starch dispersion. Get 3g mass fraction and be 10% OSA starch dispersion liquid, 4.5g chitosan mass fraction is 2%, the aqueous solution that glacial acetic acid mass fraction is 1%, 2.5g deionized water mix uniformly, can obtain OSA starch mass fraction 3%, chitosan mass fraction of 0.9% mixed dispersion. Put 1ml of the above-mentioned OSA starch mass fraction of 3%, chitosan mass fraction of 0.9% mixed dispersion, 3ml of n-hexane in a 10ml centrifuge tube, and shake it by hand ...

Embodiment 2

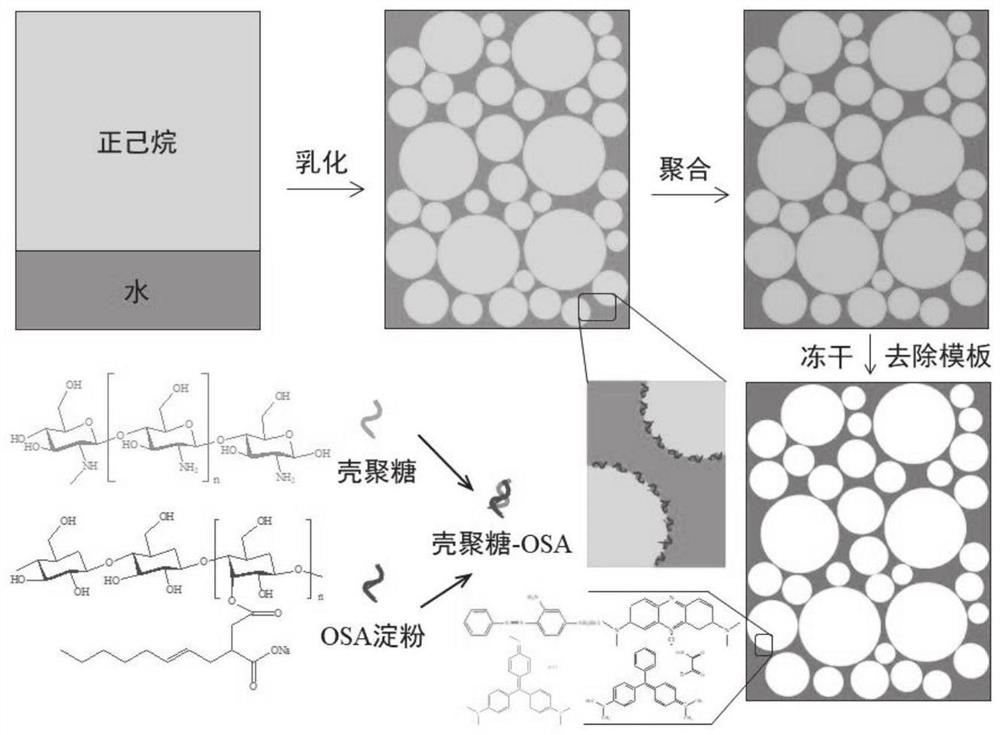

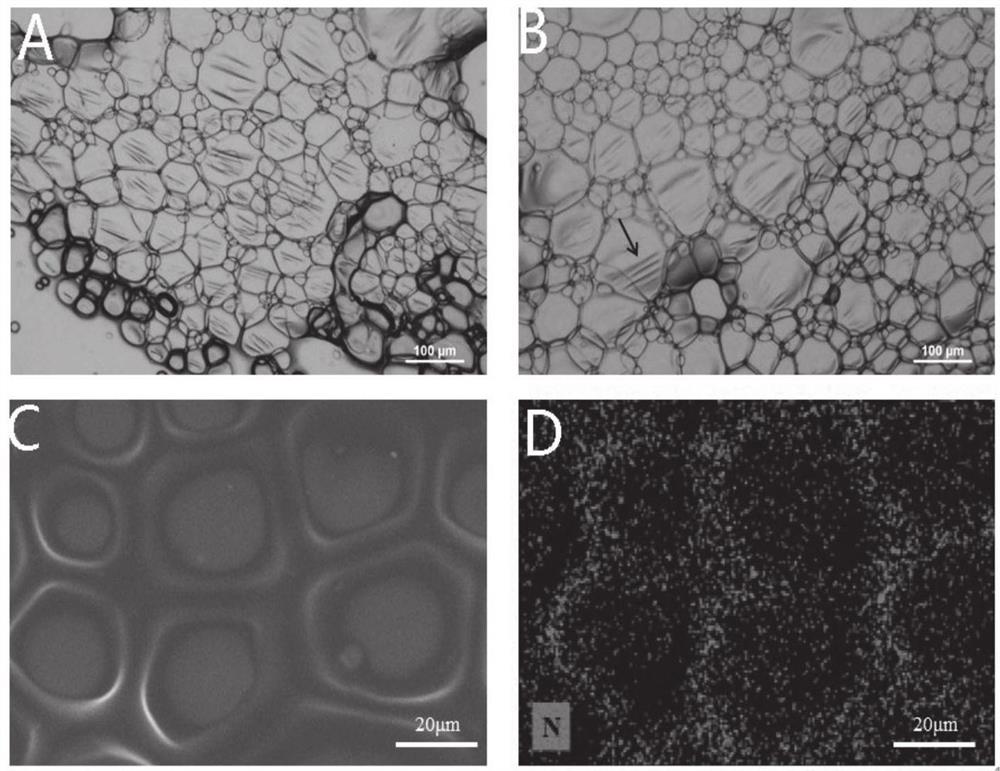

[0067] Taking the high internal phase Pickering emulsion described in Example 1 as the macroporous aerogel prepared as a template, the specific preparation method is as follows (the preparation process is as follows: figure 1 shown):

[0068] Prepare the N,N-methylenebisacrylamide dispersion in advance, take 0.4g N,N-methylenebisacrylamide and dissolve it in 10g water, heat it with ultrasonic to disperse evenly, and you can get the mass fraction of 4%N,N- Methylenebisacrylamide solution. Take 1f of the emulsion prepared above (the oil-water ratio is 3:1, the mass fraction of chitosan is 0.9%, the concentration of OSA starch is 3%), add 0.1g of acrylic acid, and 125 μL of 4% N,N-methylene Bisacrylamide solution, 50 μL diethoxyacetophenone, and 25 μL tetramethylethylenediamine were mixed by hand to obtain a precursor solution. Take a 10ml small beaker, inject the precursor solution into it, put the beaker in an ice-water bath, and cover the surface with plastic wrap to prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com