MOR molecular sieve with high silica-alumina ratio and preparation method thereof

A high-silicon-aluminum ratio, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of long crystallization time, high crystallization temperature, and low crystallinity, and reduce crystallization temperature, reduce production cost, and improve the effect of silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a high silicon-aluminum ratio MOR molecular sieve, comprising the following steps:

[0031] (1) Mix silicon source, aluminum source, sodium hydroxide, and water, and age to obtain a gel;

[0032] (2) freezing the gel and drying it in vacuum to obtain a gel powder;

[0033] (3) mixing the gel powder with water, hydrothermally crystallizing in a high-pressure reactor, washing the product until neutral, and drying to obtain a hydrothermally crystallized product;

[0034] (4) Mix the hydrothermal crystallization product with a solution with a pH of 5-13, perform post-treatment, and dry at 100-120° C. for 6-12 hours to obtain a high silicon-aluminum ratio MOR molecular sieve.

[0035] In the present invention, the silicon source in step (1) is preferably white carbon black, ultrafine SiO 2 , silica sol, tetraethyl orthosilicate or water glass, and the aluminum source is preferably aluminum nitrate, aluminum sulfate, sodium meta...

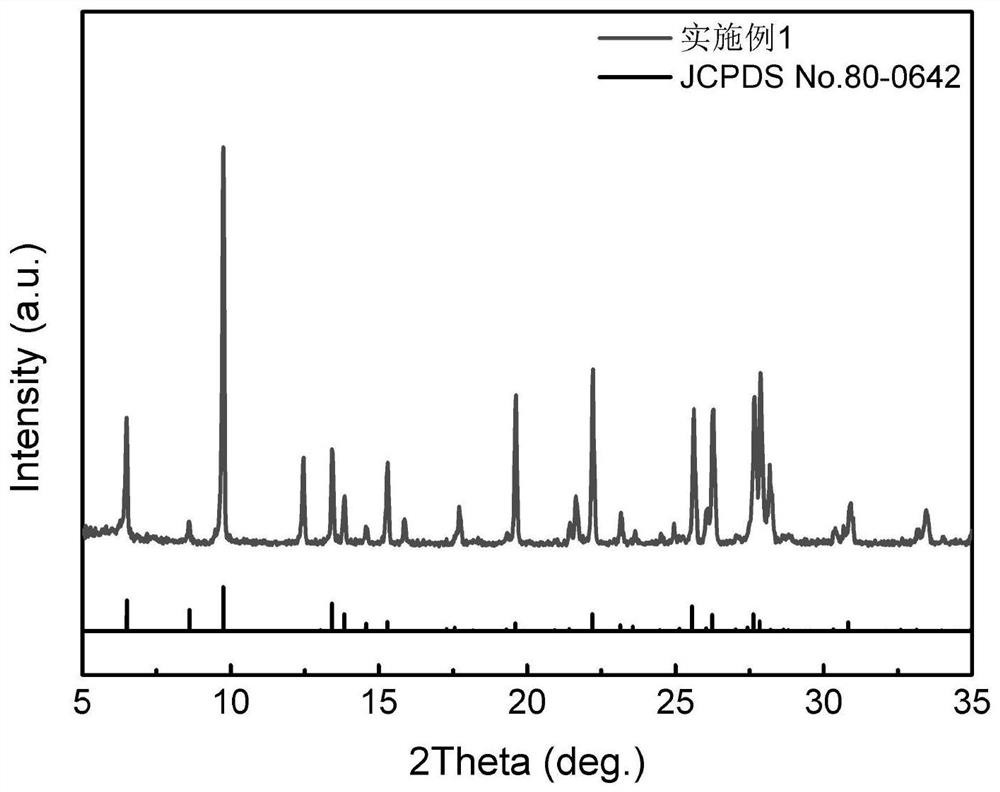

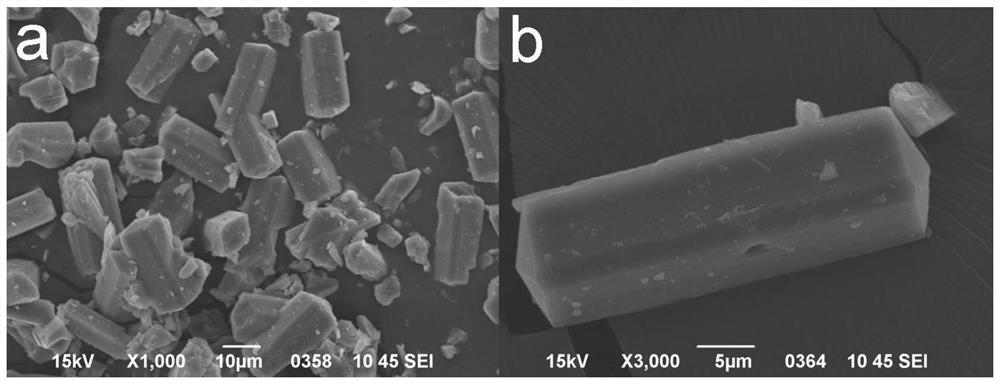

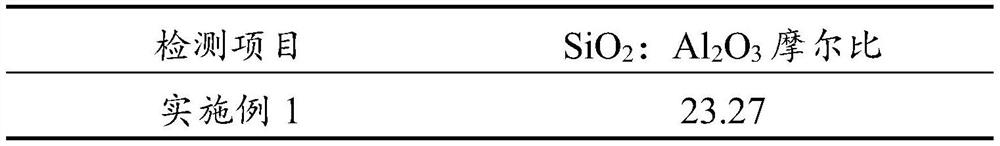

Embodiment 1

[0051] This embodiment provides a method for preparing a high silicon-aluminum ratio MOR molecular sieve, comprising the following steps:

[0052] (1) Dissolve 3.45g of granular sodium hydroxide in 30mL of water, then add 2.312g of sodium metaaluminate, and stir to a clear solution, then slowly add 67.96g of silica sol (25wt%) dropwise to the clear solution, at 25 ℃ stirring and aging for 4 hours to obtain a gel;

[0053] (2) Freezing the gel with liquid nitrogen, freezing at -35°C for 24h, introducing an ice crystal template, and then drying at 0°C for 12h under a vacuum of 3Pa to obtain a gel powder;

[0054] (3) Put 2g of gel powder in 10mL of water and stir evenly, and place it in a high-pressure reactor for hydrothermal crystallization at 120°C for 24 hours, then raise the temperature to 160°C for hydrothermal crystallization for 48 hours; after the reaction, centrifuge the solid sample 1. After washing to neutrality, drying at 120°C for 12 hours to obtain a hydrothermal...

Embodiment 2

[0058] This embodiment provides a method for preparing a high silicon-aluminum ratio MOR molecular sieve, comprising the following steps:

[0059] (1) Dissolve 4.83g of granular sodium hydroxide in 30mL of water to obtain sodium hydroxide solution, which is divided into two parts, one of which is 10mL of sodium hydroxide solution, add 0.04g of pseudo-boehmite, and stir until clear solution, add 1.22g of white carbon black to another 20mL sodium hydroxide solution, and stir until a clear solution, slowly add 10mL of clear solution to 20mL of clear solution, stir and age at 60°C for 12h to obtain a gel ;

[0060] (2) Freezing the gel with liquid nitrogen, freezing it at -80°C for 12 hours, introducing an ice crystal template, and then drying it at -10°C for 18 hours under a vacuum of 5 Pa to obtain a gel powder;

[0061] (3) Put 3g of gel powder in 4mL of water and stir evenly, and place it in a high-pressure reactor for hydrothermal crystallization at 100°C for 12h; after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com