Coal gasification fine slag water treatment device and process

A water treatment device and coal gasification technology, which is applied in multi-stage water/sewage treatment, food industry wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of frequent maintenance and replacement, high frequency of wear and replacement, environmental pollution, etc. , to achieve the effect of reducing repair and maintenance costs, reducing operation and maintenance costs, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

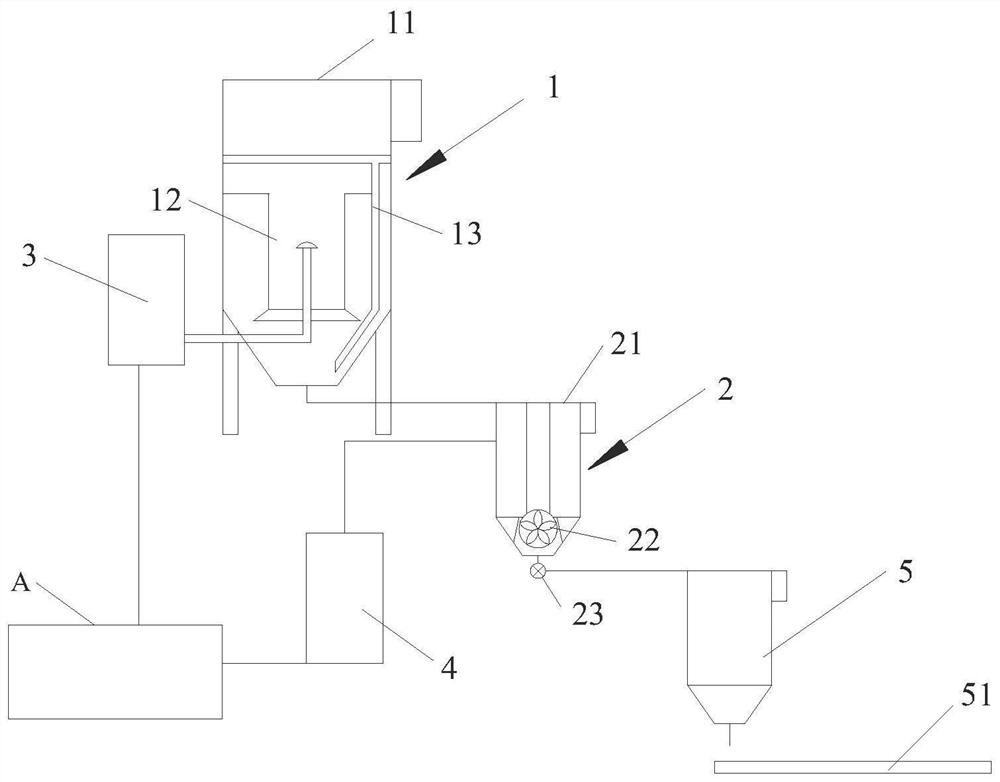

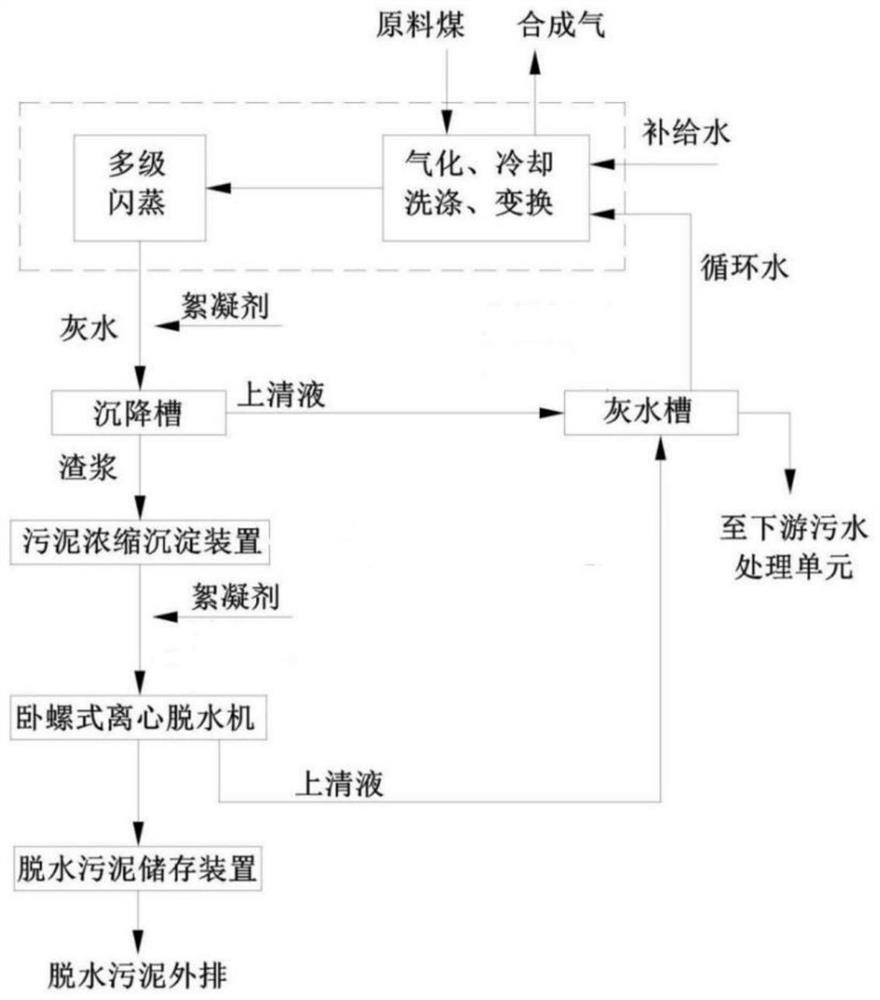

[0027] A continuous carbon nanotube purification device, comprising: a sludge concentration and precipitation device 1 and a horizontal screw centrifugal dehydrator 2, the sludge concentration and precipitation device 1 and the horizontal screw centrifugal dehydrator 2 are connected through a first sewage discharge pipe, and the sewage The mud concentration and sedimentation device 1 is also connected with a settling tank 3, and the settling tank 3 is also connected with an ash water tank 4. Preferably, the settling tank 3 and the ash water tank 4 are connected through a drain pipe, and the ash water tank 4 is also connected with the coal gasification device. The ash water tank 4 is connected with the centrifugal dehydration device 2, and the centrifugal dehydration device is also connected with a dewatered sludge storage tank 5. Preferably, a dewatered sludge storage tank 51 is also arranged under the dewatered sludge storage tank 5, and a dewatered sludge storage tank 51 is ar...

Embodiment 2

[0034] A continuous carbon nanotube purification device, comprising: a sludge concentration and precipitation device 1 and a horizontal screw centrifugal dehydrator 2, the sludge concentration and precipitation device 1 and the horizontal screw centrifugal dehydrator 2 are connected through a first sewage discharge pipe, and the sewage The mud concentration and sedimentation device 1 is also connected with a settling tank 3, and the settling tank 3 is also connected with an ash water tank 4. Preferably, the settling tank 3 and the ash water tank 4 are connected through a drain pipe, and the ash water tank 4 is also connected with the coal gasification device. The ash water tank 4 is connected with the centrifugal dehydration device 2, and the centrifugal dehydration device is also connected with a dewatered sludge storage tank 5. Preferably, a dewatered sludge storage tank 51 is also arranged under the dewatered sludge storage tank 5, and a dewatered sludge storage tank 51 is ar...

Embodiment 3

[0041] A continuous carbon nanotube purification device, comprising: a sludge concentration and precipitation device 1 and a horizontal screw centrifugal dehydrator 2, the sludge concentration and precipitation device 1 and the horizontal screw centrifugal dehydrator 2 are connected through a first sewage discharge pipe, and the sewage The mud concentration and sedimentation device 1 is also connected with a settling tank 3, and the settling tank 3 is also connected with an ash water tank 4. Preferably, the settling tank 3 and the ash water tank 4 are connected through a drain pipe, and the ash water tank 4 is also connected with the coal gasification device. The ash water tank 4 is connected with the centrifugal dehydration device 2, and the centrifugal dehydration device is also connected with a dewatered sludge storage tank 5. Preferably, a dewatered sludge storage tank 51 is also arranged under the dewatered sludge storage tank 5, and a dewatered sludge storage tank 51 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com