Preparation method of ultra-light shoe sole with hydrogen explosion structure, shoe sole and sneakers

A sports shoe, ultra-light technology, applied in the direction of soles, footwear, applications, etc., can solve the problems of poor rigidity, achieve the effect of enhancing mechanical strength and toughness, enhancing elasticity, and enhancing connection fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

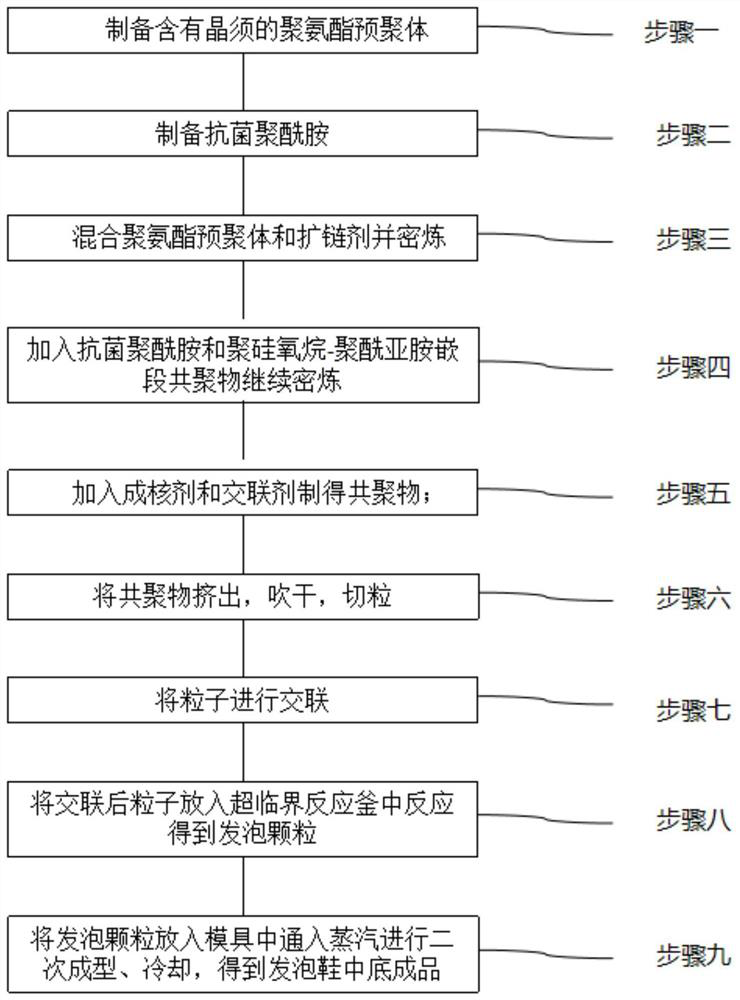

Method used

Image

Examples

Embodiment approach 1

[0050]As Embodiment 1 of the present invention, the present invention proposes a supercritical TPU composite material, which is made of raw materials including the following parts by mass: 60-70 parts of polyurethane prepolymer, 3.5-7.5 parts of whiskers 2.5-3.5 parts of chain extender, 14-24 parts of antibacterial polyamide, 7-12 parts of polysiloxane-polyimide block copolymer, 1.5-2.1 parts of nucleating agent, 1.5-1.8 parts of crosslinking agent share. Specifically, the mass content of the whiskers is 6%-8% of the polyurethane prepolymer.

Embodiment 1

[0052] A supercritical TPU composite material, the supercritical TPU composite material is made of raw materials comprising the following parts by mass: 68.0 parts of polyurethane prepolymer, 4.0 parts of whiskers, 2.6 parts of chain extender, 15.0 parts of antibacterial polyamide, poly 7.0 parts of siloxane-polyimide block copolymer, 1.8 parts of nucleating agent, and 1.6 parts of crosslinking agent. Wherein, the polyurethane prepolymer can be made by polyε-caprolactone and diphenylmethane diisocyanate, and the average molar mass of polyε-caprolactone is 2300, (in the polyurethane elastomer that it forms, R(NCO / OH) 3; the nucleating agent can be a mixture of nucleating agent TMC-328 and zinc acrylate, the chain extender can be 4-hydroxyethyloxyethyl-1-hydroxyethylphenylene ether, and the crosslinking agent is isocyanate crosslinking agent.

[0053] In this embodiment, the whiskers are CaSO4 whiskers, the antibacterial polyamide is antibacterial PA6, and the antibacterial age...

Embodiment 2

[0055] A supercritical TPU composite material, the supercritical TPU composite material is made of raw materials comprising the following parts by mass: 62.0 parts of polyurethane prepolymer, 4.5 parts of whiskers, 2.4 parts of chain extender, 18.2 parts of antibacterial polyamide, poly 9.3 parts of siloxane-polyimide block copolymer, 1.9 parts of nucleating agent, and 1.7 parts of crosslinking agent. Wherein, the polyurethane prepolymer can be made by polyε-caprolactone and diphenylmethane diisocyanate, and the average molar mass of polyε-caprolactone is 1993, and R(NCO / OH) in the polyurethane elastomer that it forms is 10. The nucleating agent can be a sorbitol nucleating agent, the chain extender can be hydroquinone bis(β-hydroxyethyl) ether, and the cross-linking agent is an isocyanate cross-linking agent.

[0056] In this embodiment, the whiskers are SiC whiskers, the antibacterial polyamide is antibacterial PA66, and the antibacterial agent used in the antibacterial poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com