Negative electrode material and preparation method thereof, and lithium ion battery comprising negative electrode material

A negative electrode material and carbon material technology, applied in the field of negative electrode materials and their preparation, can solve the problems of large thickness expansion and fast capacity decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

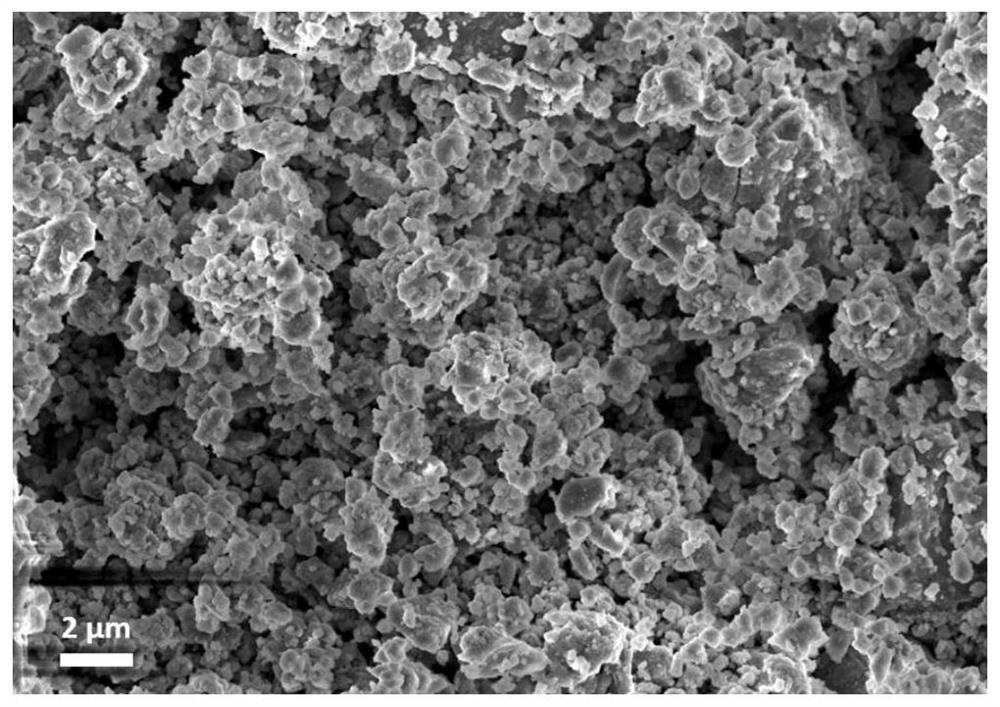

[0066] Under an inert atmosphere, ball mill the pure silicon material to obtain Si powder; the BET specific surface area of the pure silicon material is ~0.1m 2 / g, D of PSA test v 50 is ~100 μm. The BET specific surface area of the Si powder is 9.4m 2 / g, PSA test D v 50 is 0.8 μm.

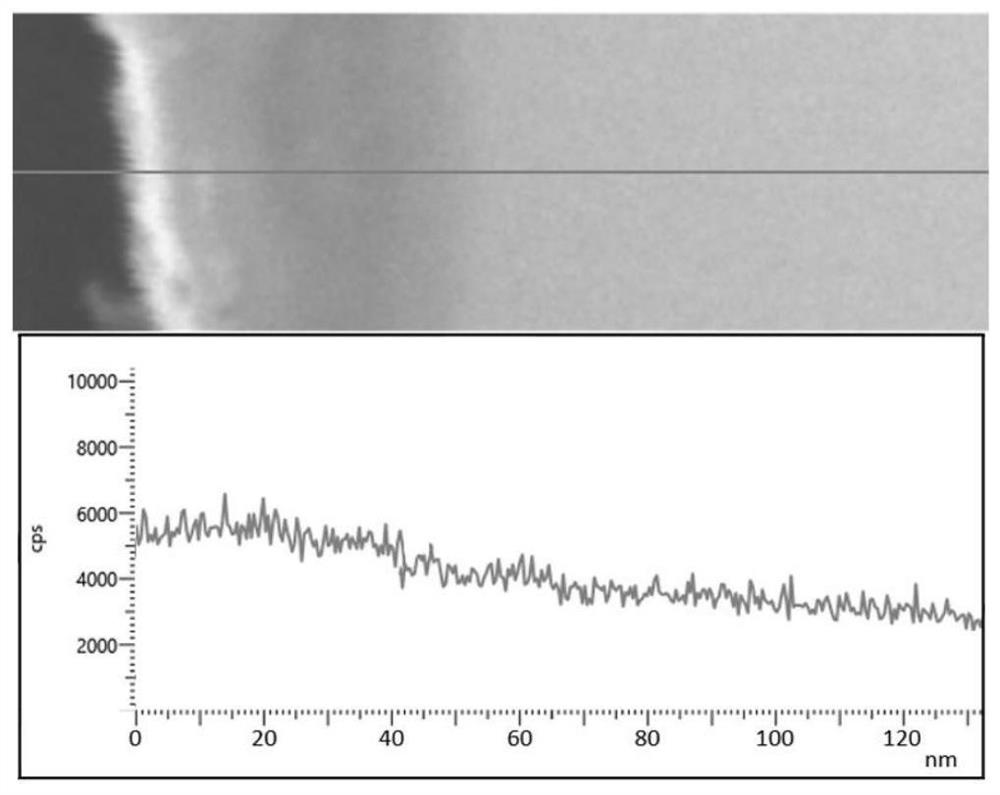

[0067] Polynaphthalene with an average molecular weight of 5000 was dissolved in toluene, and the above-mentioned Si powder was added to coat the surface of the Si powder with polynaphthalene. The mass ratio of polynaphthalene to Si powder was 15:85, and the first composite material was obtained after drying.

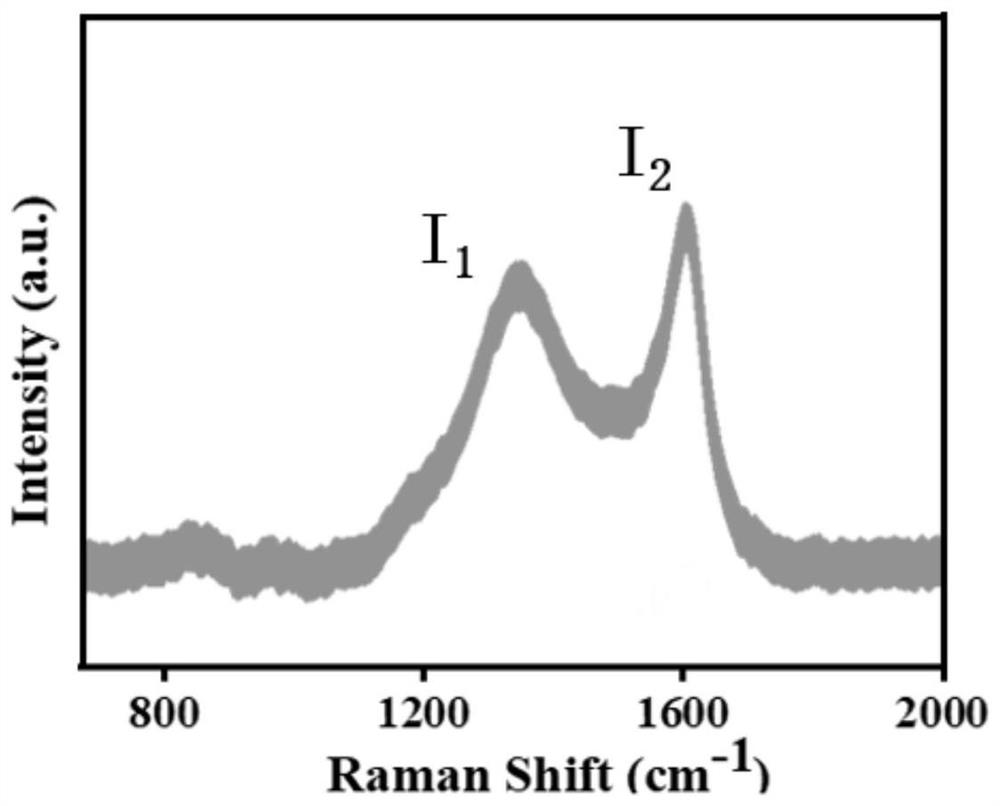

[0068] Put the above-mentioned first composite material into a high-temperature furnace, protect it with argon, raise the temperature to 250°C at a heating rate of 3°C / min, and keep it for 3 hours, and raise the temperature to 600°C at a heating rate of 3°C / min, and keep 3h, cool down naturally to obtain the second composite material.

[0069] Grinding the second composite materia...

Embodiment 2

[0077] This example is basically the same as Example 1, except that polyanthracene with an average molecular weight of 5,000 is used in the preparation of the negative electrode material instead of polynaphthalene with an average molecular weight of 5,000.

Embodiment 3

[0079] This embodiment is basically the same as Embodiment 1, except that FeSi material is used in the negative electrode material preparation process instead of pure silicon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com