A kind of preparation method of anti-pollution cross-linked anion exchange membrane based on polyvinyl alcohol

An anion exchange membrane, polyvinyl alcohol technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problem of weak skeleton rigidity, and achieve the effect of excellent attenuation, high stability, and excellent anti-pollution performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

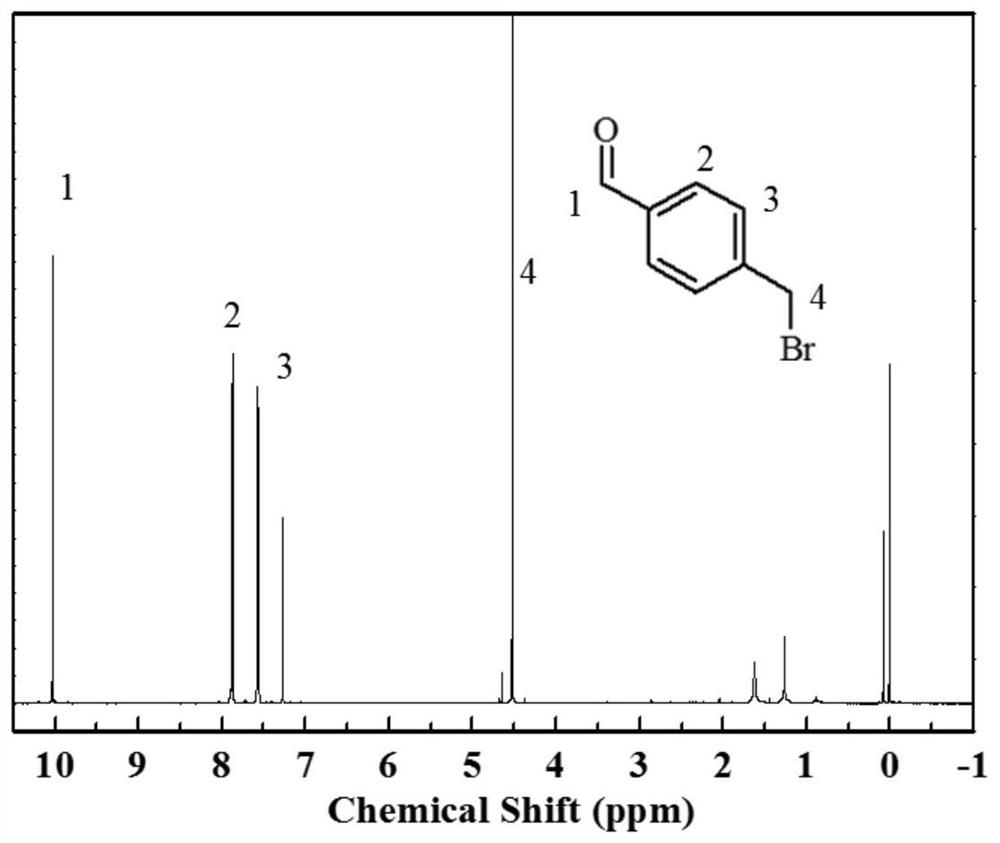

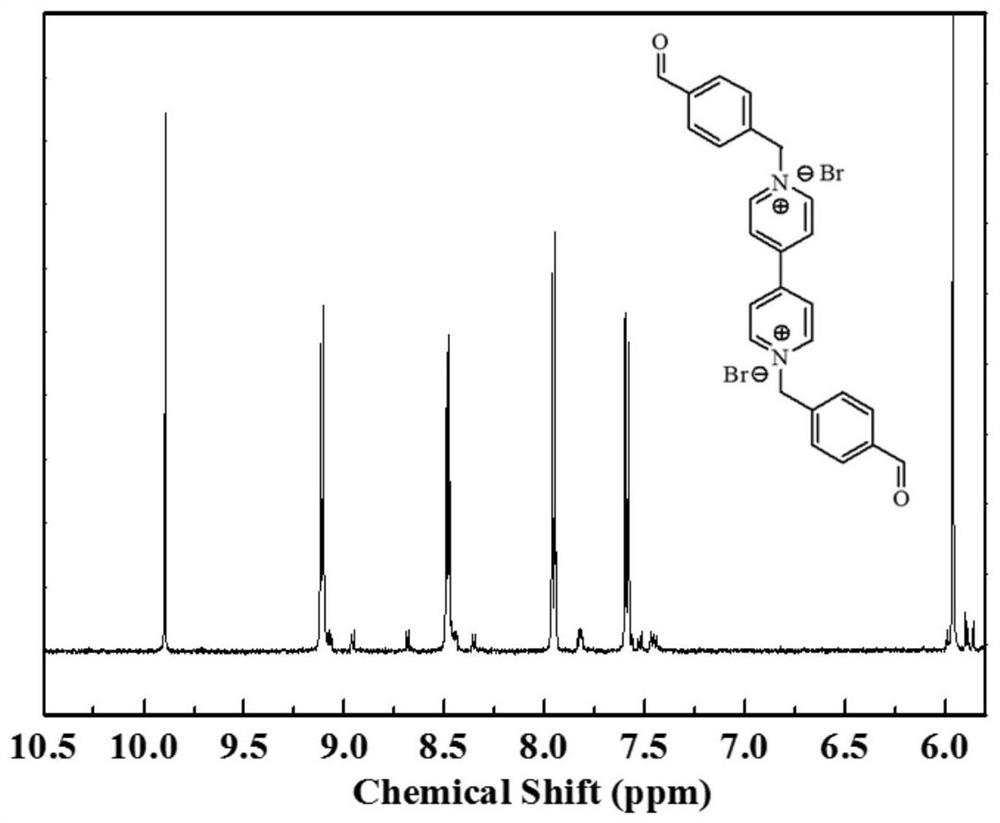

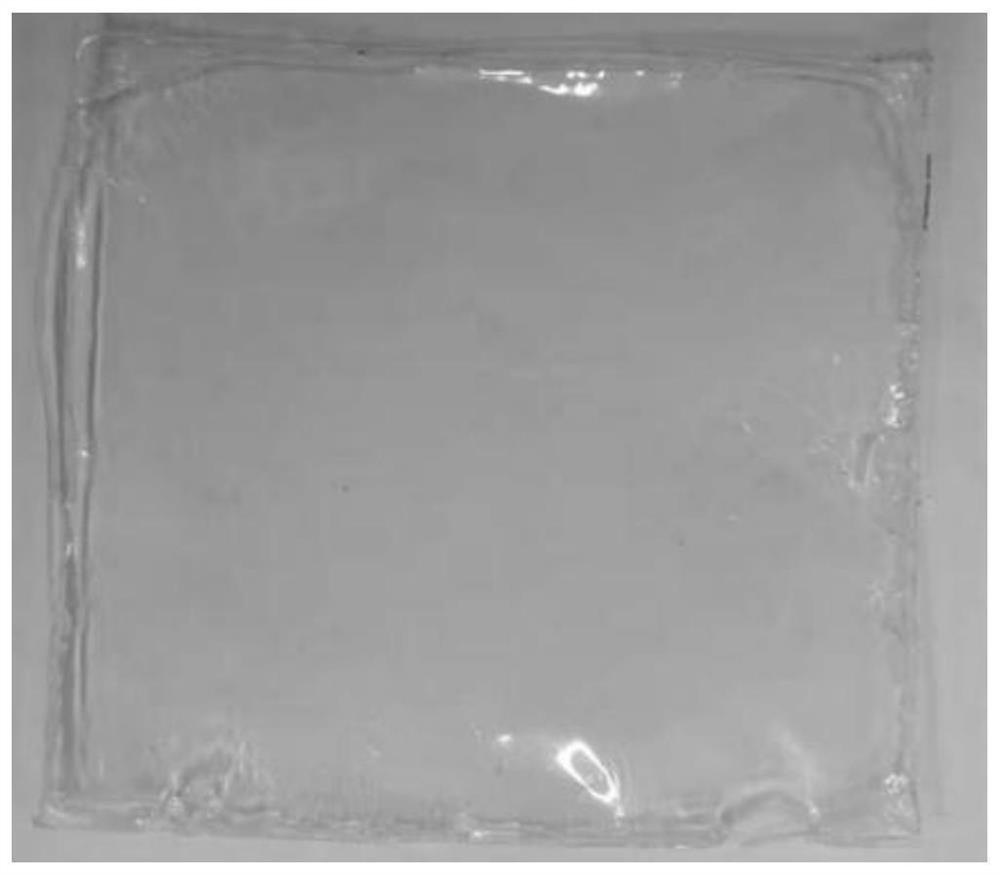

[0047] (1) Synthesis of 4-bromomethylbenzaldehyde: Weigh 5.00 g (25.5 mmol) of 4-(bromomethyl)benzonitrile (CBB) and fully dissolve it in 100 mL of toluene. In the absence of oxygen, 38.5 mL of a toluene solution of diisobutylaluminum hydride (DIBAL-H) was added dropwise, and the mixture was stirred under an ice bath for 1 hour. Then, the remaining DIBAL-H was quenched with 10 mL of saturated ammonium chloride solution, and the organic phase of the mixed solution obtained after the reaction was extracted with ethyl acetate, and the obtained organic phase was treated with anhydrous MgSO 4 dry. The ethyl acetate was removed by rotary evaporation at 40°C to obtain a pale yellow crude product. Then use a chromatographic column for separation and purification (mobile phase volume ratio: petroleum ether: ethyl acetate = 100: 1) to remove by-products. The petroleum ether and ethyl acetate were removed by rotary evaporation to obtain 4.75 g of white 4-bromomethylbenzaldehyde (BMBD...

Embodiment 2

[0054] (1) Synthesis of 4-bromomethylbenzaldehyde: adopt the same preparation process as Example 1.

[0055] (2) Synthesis of 4-pyridylbenzaldehyde: The same preparation process as in Example 1 was adopted.

[0056] (3) Preparation of crosslinking agent containing bipyridine structure: the same preparation process as in Example 1 was adopted.

[0057] (4) Preparation of cross-linked ion exchange membrane: the same preparation process as in Example 1 was adopted, and the difference was that p-trifluoromethyl benzaldehyde, 4-pyridyl benzaldehyde and the cross-linking agent containing bipyridine structure The molar ratio was 20:10:4, and the masses were 3.7630 g, 2.7814 g, and 2.2171 g, respectively (see Table 1); the thickness of the obtained anion exchange membrane was 119 μm.

[0058] (5) Performance evaluation of cross-linked ion exchange membrane:

[0059] The parameters such as ion exchange capacity, sheet resistance, tensile strength and elongation at break, water absorp...

Embodiment 3

[0061] (1) Synthesis of 4-bromomethylbenzaldehyde: adopt the same preparation process as Example 1.

[0062] (2) Synthesis of 4-pyridylbenzaldehyde: The same preparation process as in Example 1 was adopted.

[0063] (3) Preparation of crosslinking agent containing bipyridine structure: the same preparation process as in Example 1 was adopted.

[0064] (4) Preparation of cross-linked ion exchange membrane: the same preparation process as in Example 1 was adopted, and the difference was that p-trifluoromethyl benzaldehyde, 4-pyridyl benzaldehyde and the cross-linking agent containing bipyridine structure The molar ratio was 25:10:4, and the masses were 4.7038 g, 2.7814 g, and 2.2171 g, respectively (see Table 1); the thickness of the obtained anion exchange membrane was 116 μm.

[0065] (5) Performance evaluation of cross-linked ion exchange membrane:

[0066] The parameters such as ion exchange capacity, sheet resistance, tensile strength and elongation at break, water absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com