Polyimide/silver composite membrane with electromagnetic shielding function and preparation method thereof

A technology of polyimide and electromagnetic shielding, which is applied in the field of polyimide/silver composite film and its preparation, can solve the problems of large environmental pollution of the plating solution, poor adhesion between silver particles and the substrate, and complicated operation, and achieve large Mechanical properties, excellent electrical conductivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

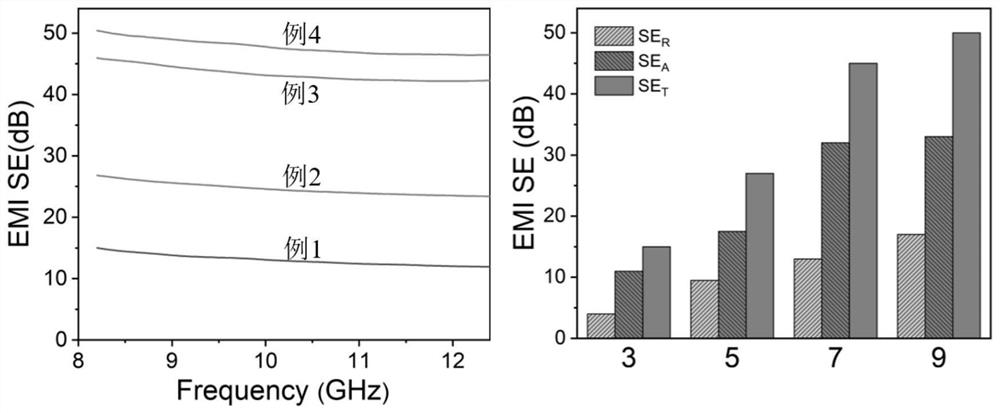

Embodiment 1

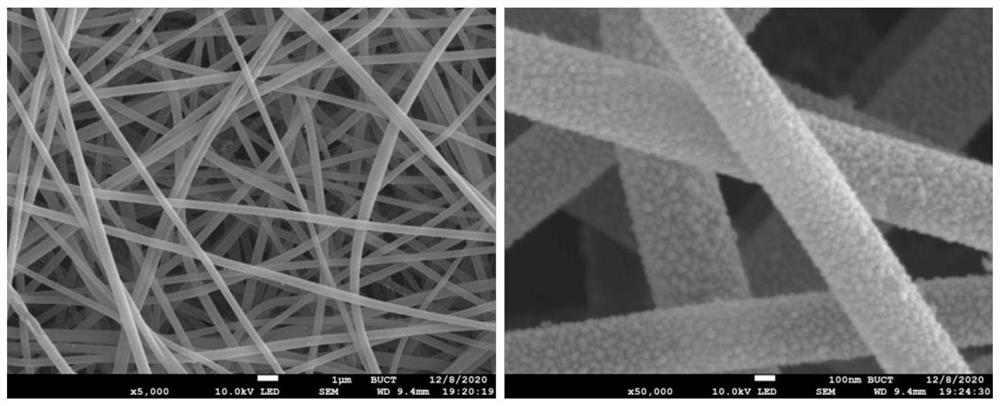

[0030] Prepare a PMDA / ODA system polyamic acid nanofiber membrane with a solid content of 12% and soak it to a concentration of 0.2mol / L AgNO 3 After 10 minutes in the solution, ultrasonic cleaning was performed, the ion-exchanged fiber membrane was placed in 0.1mol / L DMAB solution for reduction, and PAA with a solid content of 5% was coated on the surface, and PI coating was obtained after thermal imidization treatment. PI / Ag nanofiber composite film.

[0031] (1) Weigh 2.03g of pyromellitic dianhydride (PMDA) and 1.84g of 4,4'-diaminodiphenyl ether (ODA) in the same molar ratio, start the mechanical stirring, and dissolve ODA in 30ml of N, In the N-dimethylformamide (DMF) solvent, after being completely dissolved, PMDA was added in batches under the condition of an ice-water bath, and the mechanical stirring was continued until the axial wrapping effect appeared to obtain a moderately viscous polyamic acid solution. Put the polyamic acid solution into a 20ml syringe, and pr...

Embodiment 2

[0037] Prepare a BTDA / ODA system polyamic acid nanofiber membrane with a solid content of 12%, soak it in a silver acetate solution with a concentration of 0.2mol / L, ultrasonically clean it after 10min, and place the ion-exchanged fiber membrane in a 0.1mol / L Reduction was carried out in DMAB solution, PAA with a solid content of 20% was coated on the surface with a thickness of 5 μm, and a PI / Ag nanofiber composite film coated with PI was obtained after thermal imidization treatment.

[0038] (1) Weigh 2.38g of 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA) and 1.48g of 4,4'-diaminodiphenyl ether (ODA) in the same molar ratio, and turn on the machine Stir, dissolve all the ODA in 30ml of N,N-dimethylformamide (DMF) solvent. After it is completely dissolved, add BTDA in batches under the condition of an ice-water bath, and continue mechanical stirring until the axial wrapping effect occurs. A polyamic acid solution with moderate viscosity was obtained. Put the polyamic ac...

Embodiment 3

[0044] Prepare a BTDA / ODA system polyamic acid nanofiber membrane with a solid content of 15%, soak it in a silver sulfate solution with a concentration of 0.08mol / L, ultrasonically clean it after 10min, and place the ion-exchanged fiber membrane in a 0.2mol / L Carry out reduction in ascorbic acid solution, coat PAA with a solid content of 12% on its surface with a coating thickness of 100 microns, and obtain a PI-coated PI / Ag nanofiber composite film after thermal imidization treatment.

[0045] (1) Weigh 3.09g of 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA) and 1.92g of 4,4'-diaminodiphenyl ether (ODA) in the same molar ratio, and turn on the machine Stir, dissolve all the ODA in 30ml of N,N-dimethylformamide (DMF) solvent. After it is completely dissolved, add BTDA in batches under the condition of an ice-water bath, and continue mechanical stirring until the axial wrapping effect occurs. A polyamic acid solution with moderate viscosity was obtained. Put the polyamic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com