System and method for monitoring and controlling temperature and optical power of optical waveguide device in situ

A device temperature, monitoring and control technology, applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve the problems of inaccurate monitoring of the actual temperature of the optical waveguide, inaccurate optical power of the optical waveguide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

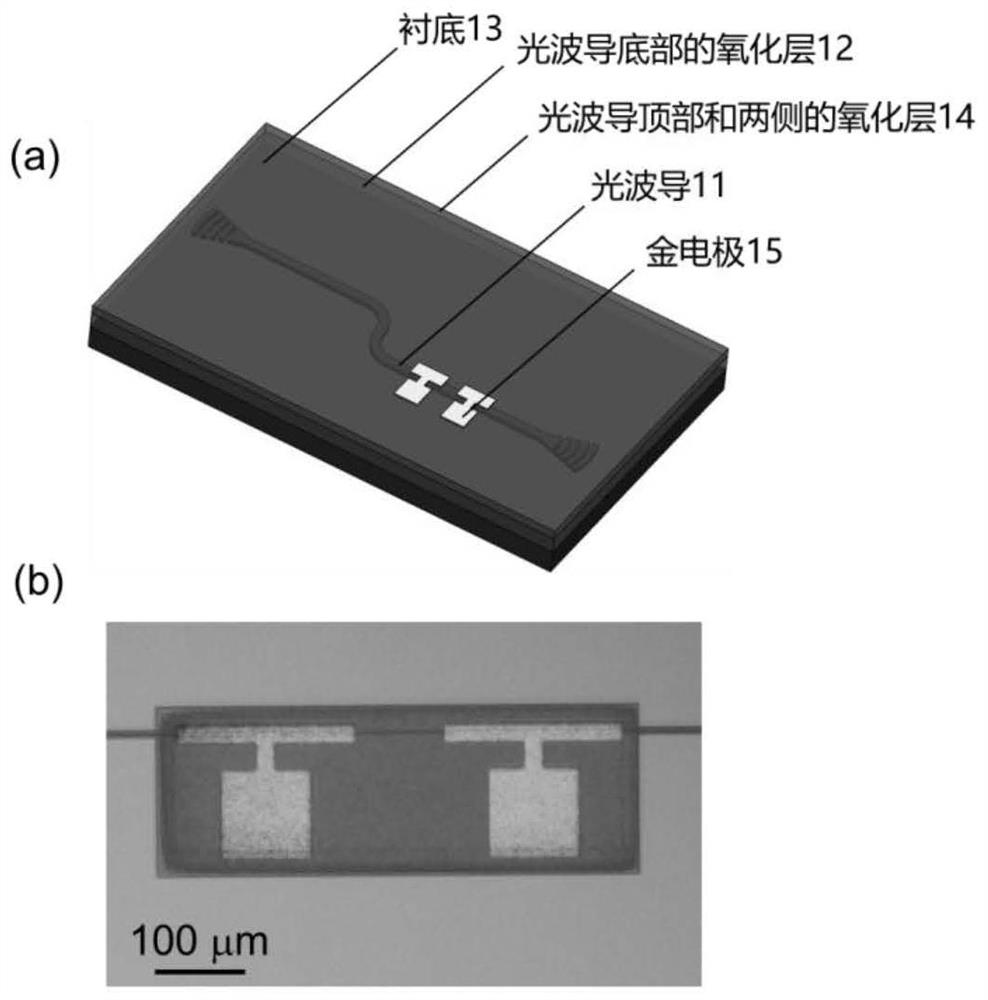

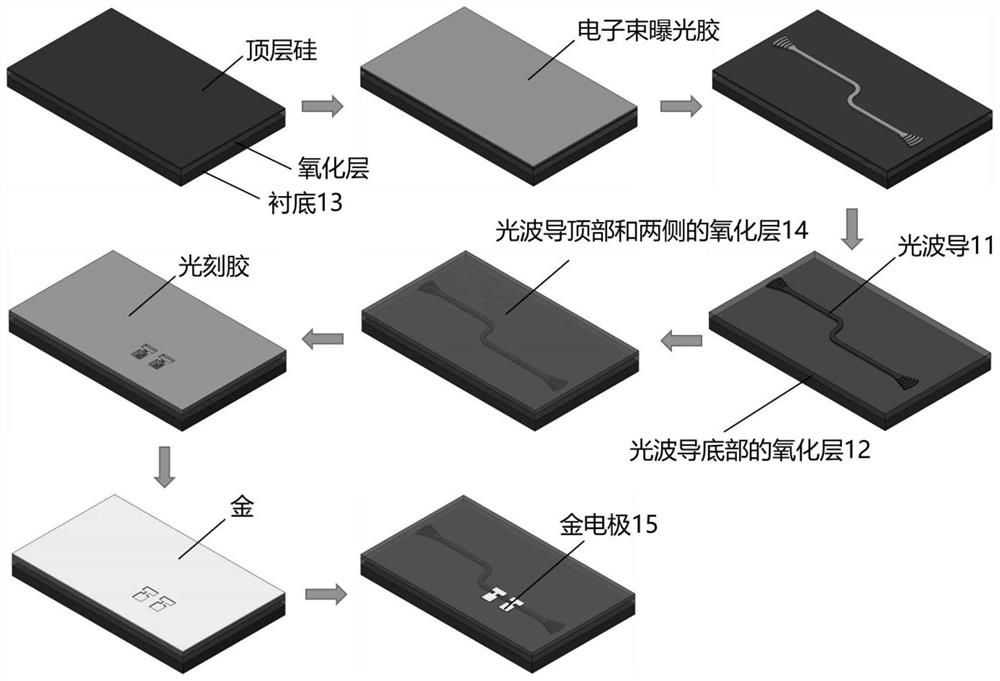

[0058] The processing flow chart of CLIPP 1 is as follows: figure 2 shown. First, the structure of the optical waveguide is defined by scanning electron beam exposure (SEBL), and the optical waveguide 11 is processed by transferring the electron beam exposure glue pattern to the device layer by inductively coupled plasma etching (ICP), and the residual glue after etching is removed by using an organic solvent ; Utilize ion-enhanced chemical vapor deposition (PECVD) to deposit silicon dioxide layer afterwards as the upper cladding of optical waveguide; Finally, utilize ultraviolet lithography to engrave gold electrode 15 patterns, utilize sputtering to deposit titanium gold, lift off in organic solvent , remove excess photoresist and metal, and process the titanium-gold electrode 15 .

Embodiment approach 2

[0060] When the optical power of the integrated optical waveguide device changes, the surface state absorption effect will cause the admittance of the optical waveguide to change; when the temperature of the integrated optical waveguide device changes, the temperature-induced changes in the number of carriers and mobility of the optical waveguide also Will cause the admittance of the optical waveguide to change. Based on the above properties of the optical waveguide, the temperature and optical power monitoring of the integrated optical waveguide device can be realized by using CLIPP 1.

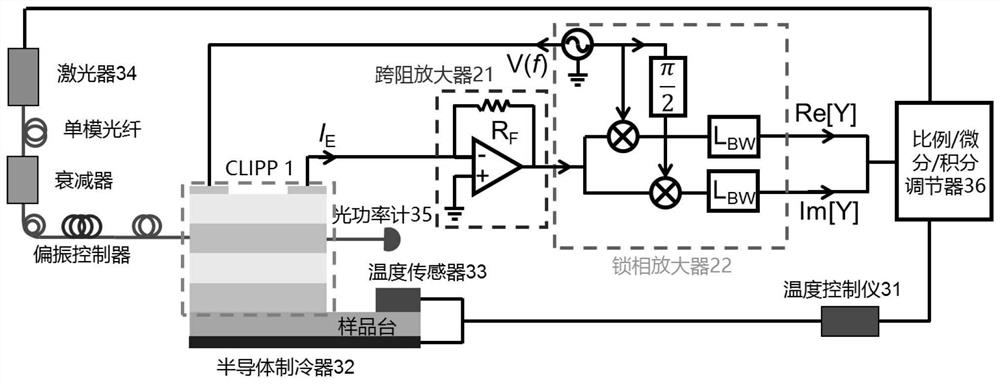

[0061] image 3 Schematic diagram of the device for simultaneous in-situ monitoring and control of the temperature and optical power of the integrated optical waveguide device. The lock-in amplifier 22 outputs a sinusoidal voltage signal with adjustable frequency. The signal is input through the titanium gold electrode at one end of CLIPP 1 and output from the titanium gold electrode at the ...

Embodiment approach 3

[0063] Simultaneous monitoring of temperature and optical power of integrated optical waveguide devices:

[0064] Measure the relationship between the change of admittance and the temperature and optical power at the driving frequency of 1MHz and 5MHz, and it can be obtained by linear interpolation Image 6 (a) The scanning diagram of the admittance variation of temperature and optical power under the two driving frequencies shown in (a). Measure the admittance change of the two driving frequencies of 1MHz and 5MHz at the same temperature and optical power, and form two constant admittance change planes, and then Image 6 The surface in (a) is intercepted, and the projection of the obtained two curves on the temperature-optical power plane (such as Image 6 (a) The intersection point corresponds to the temperature and optical power of the current integrated optical waveguide device, such as Image 6 (b) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com