Composite negative plate and preparation method thereof, and secondary battery

A technology of negative electrode sheet and conductive agent, which is applied in the direction of secondary battery, negative electrode, battery electrode, etc., can solve the problem that the negative electrode sheet is difficult to increase capacity and cycle stability at the same time, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

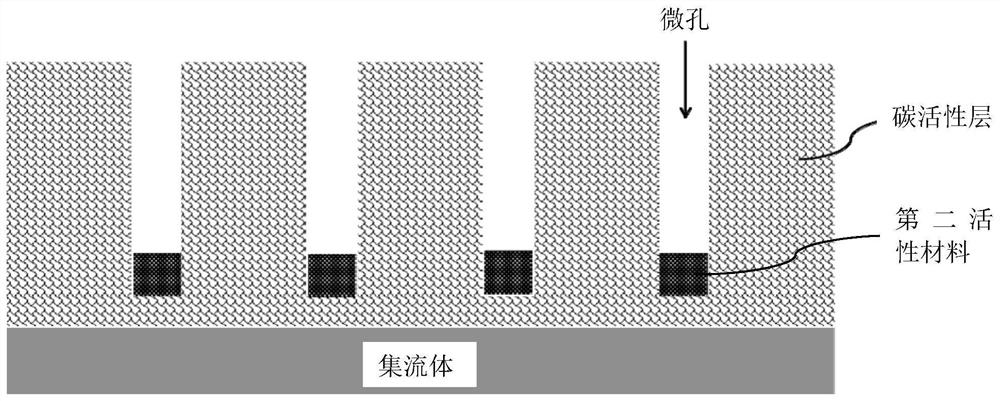

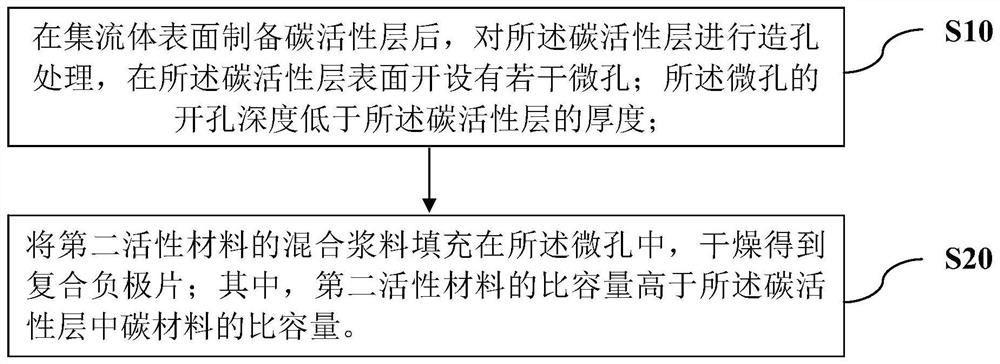

[0074] as attached figure 2 As shown, the second aspect of the embodiment of the present invention provides a method for preparing a composite negative electrode sheet, comprising the following steps:

[0075] S10. After the carbon active layer is prepared on the surface of the current collector, the carbon active layer is subjected to pore-forming treatment, and a number of micropores are opened on the surface of the carbon active layer; the opening depth of the micropores is lower than the thickness of the carbon active layer;

[0076] S20. Fill the micropores with the mixed slurry of the second active material, and dry to obtain a composite negative electrode sheet; wherein, the specific capacity of the second active material is higher than that of the carbon material in the carbon active layer.

[0077] In the preparation method of the composite negative electrode sheet provided by the second aspect of the embodiment of the present invention, after the carbon active layer...

Embodiment 1

[0099] A kind of composite negative plate , its preparation includes the steps of:

[0100]1. Mix graphite powder with a particle size D50 of 12 microns with carbon black powder, CMC and SBR, and stir to make graphite negative electrode slurry. The content of graphite powder is 85%, the content of carbon black is 5%, and the binder CMC and SBR content is 10%.

[0101] 2. Take the graphite negative electrode slurry prepared in step (1), apply it on the copper foil, and dry it to obtain the negative electrode. Increase the density of the graphite negative electrode to 1.6 g / cm by rolling, etc. 3 .

[0102] 3. The graphite negative electrode with a thickness of 110 μm obtained in step (2) is punched out by pulsed laser ablation into a square array of holes with a diameter of 60 μm and a hole depth of 100 μm.

[0103] 4. Mix silicon oxide powder with a particle size D50 of 5 microns, carbon black powder, and binder PAA, and stir to make a silicon oxide negative electrode slur...

Embodiment 2

[0107] A kind of composite negative plate , which differs from Example 1 in that: in step 4, silicon powder is used instead of silicon-oxygen powder.

[0108] a secondary battery , Assemble the composite negative electrode sheet prepared in Example 2, NCM811 positive electrode sheet, 12+4 ceramic diaphragm, and high-nickel electrolyte into a pouch battery. The designed battery capacity is 9Ah, and the battery size is 80*60*8.55mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com