Flame retardant containing DOPS/phosphazene structure as well as preparation method and application thereof

A technology of flame retardant and phosphazene, which is applied in the field of flame retardant materials, can solve the problems of reduced mechanical properties of polymer materials, low flame retardant efficiency, poor char formation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] According to one aspect of the present invention, a kind of preparation method of above-mentioned flame retardant containing DOPS / phosphazene structure, described preparation method comprises the following steps:

[0058] (a) Using hexachlorocyclotriphosphazene and 4-hydroxybenzaldehyde and optional phenol as raw materials, add an acid-binding agent to carry out a nucleophilic substitution reaction in a substitution reaction solvent, followed by filtration, distillation, washing and drying , to obtain a cyclotriphosphazene compound containing an aldehyde group;

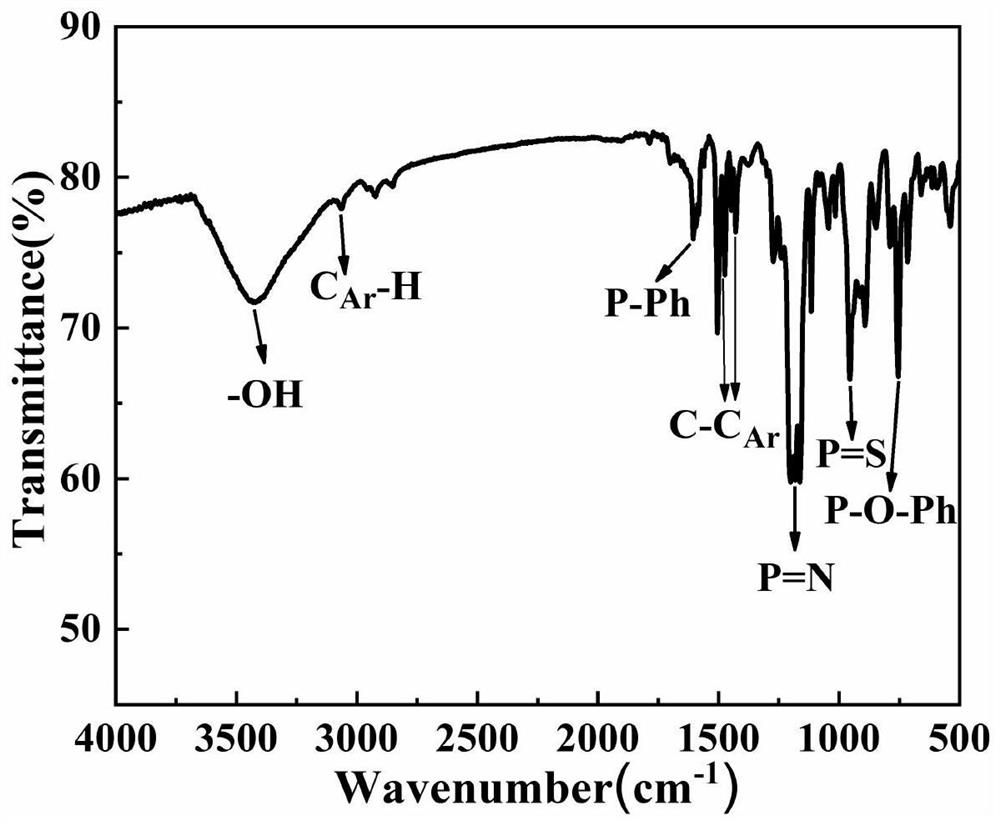

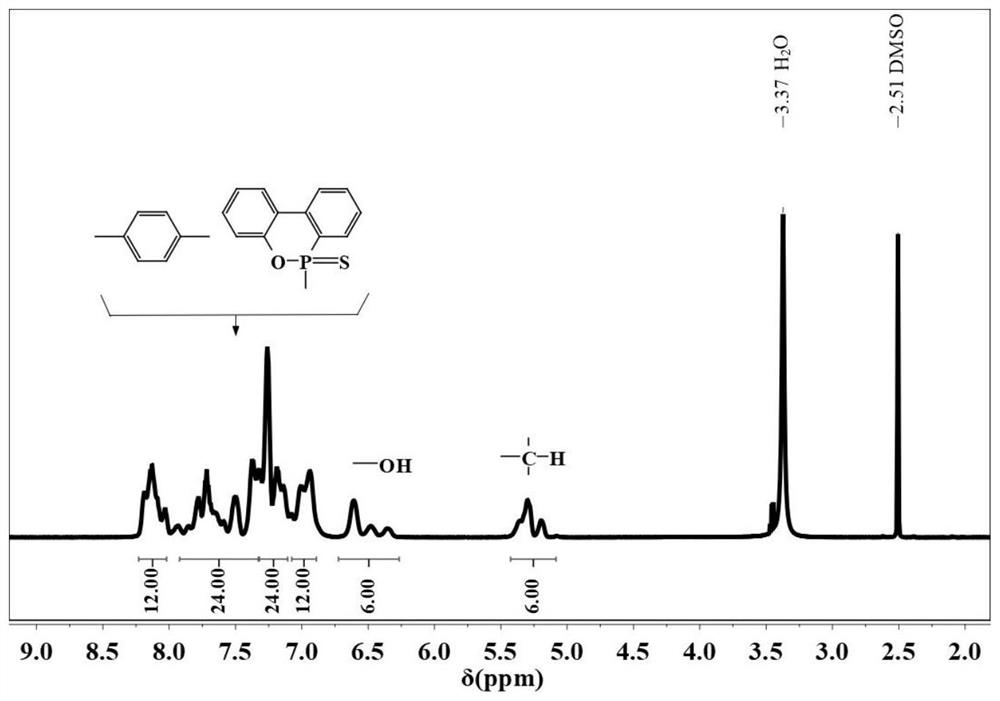

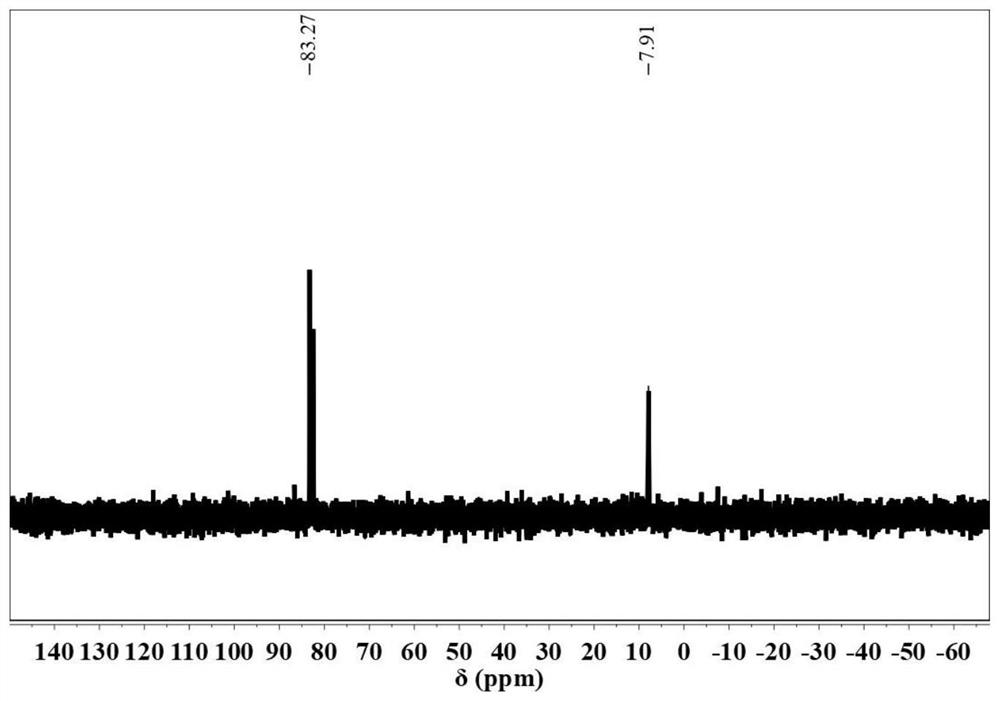

[0059] (b) carry out addition reaction with the cyclotriphosphazene compound and DOPS containing the aldehyde group that step (a) makes in the addition reaction solvent, wash, filter and dry successively subsequently, obtain the compound containing DOPS / phosphazene structure flame retardant.

[0060] The preparation method of the flame retardant containing DOPS / phosphazene structure provided by the present inv...

Embodiment 1

[0081] A kind of flame retardant containing DOPS / phosphazene structure, the preparation method of the described flame retardant containing DOPS / phosphazene structure comprises the following steps:

[0082] (a) Preparation of HAP

[0083] 1. HCCP and 4-hydroxybenzaldehyde are weighed according to the molar ratio of 1:7;

[0084] 2. Use the organic solvent tetrahydrofuran as the reaction medium, so that the reactants can fully react;

[0085] 3. Add the weighed 4-hydroxybenzaldehyde into a three-necked flask equipped with a thermometer, condenser, and stirrer, add an appropriate amount of solvent and acid-binding agent triethylamine, install a reflux condensation device, and raise the temperature to 60°C. Then add an appropriate amount of solvent to the weighed HCCP, and after it is completely dissolved, add it dropwise to the above reaction system within 1 hour. After the addition is complete, raise the temperature to 65°C and continue the reflux reaction for 20 hours;

[008...

Embodiment 2

[0099] A kind of flame retardant containing DOPS / phosphazene structure, the preparation method of the described flame retardant containing DOPS / phosphazene structure comprises the following steps:

[0100] (a) Preparation of HAP

[0101] 1. HCCP and 4-hydroxybenzaldehyde are weighed according to the molar ratio of 1:6;

[0102] 2,3, with embodiment 1;

[0103] Finally, the product HAP was obtained as a white powdery solid with a melting point of 156.3-157.4° C., a yield of 97.2%, and a purity of >99.0%.

[0104] (b) Preparation of HAP-DOPS

[0105] 1. Weigh DOPS and HAP according to the molar ratio of 8:1;

[0106] 2. Use the mixed solution of organic solvent chlorobenzene and ethanol as the reaction medium, so that the reactants can fully react;

[0107] 3. Add the weighed DOPS into a four-necked flask equipped with a thermometer, condenser tube, stirrer and protective gas inlet and outlet, add an appropriate amount of solvent and triethylamine, install a reflux condensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com