Insulating anti-corrosive coating for cables

An anti-corrosion coating and cable technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of cable insulation and anti-corrosion performance to be improved, and achieve good insulation effect and corrosion resistance. , avoid brittleness, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

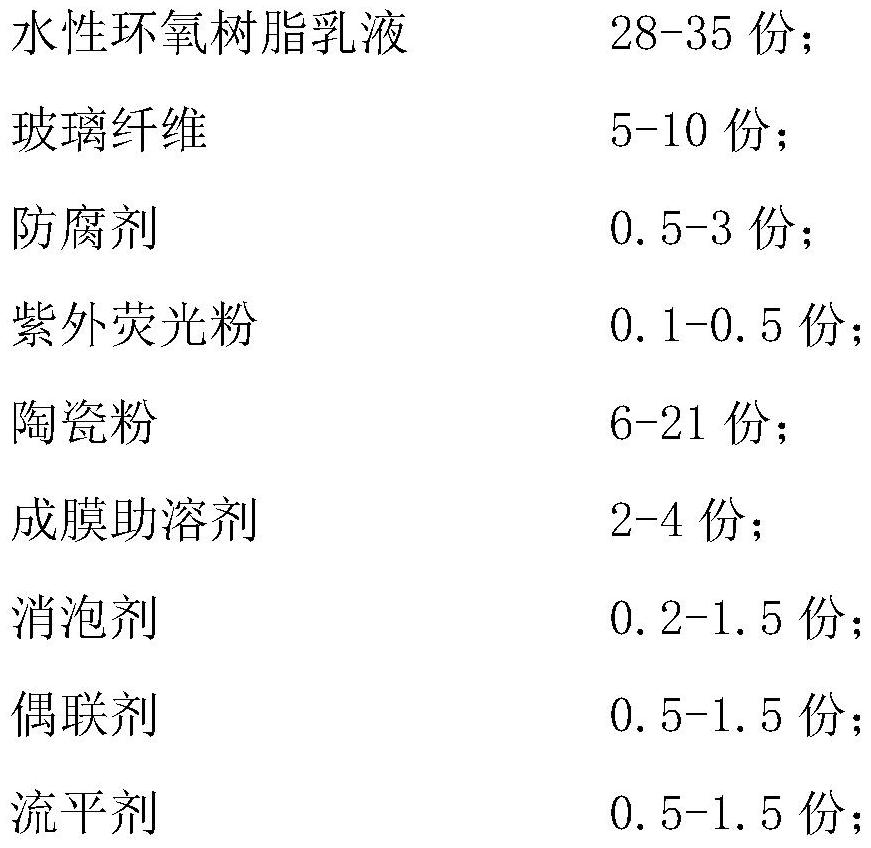

[0041] An insulating and anti-corrosion coating for electric cables, according to the mass fraction ratio, its formula includes the following components:

[0042] A component:

[0043] 28 parts of aqueous epoxy resin emulsion;

[0044] 10 parts of glass fiber;

[0045] Glass fiber diameter 10μm;

[0046] 3 parts preservative;

[0047] 0.5 part of ultraviolet fluorescent powder;

[0048] The particle size of ultraviolet fluorescent powder is 5μm, which can be developed under ultraviolet light with a wavelength of 190-400nm;

[0049] 21 parts ceramic powder;

[0050] The particle size of ceramic powder is 10μm;

[0051] 2 parts of film-forming auxiliary solvent;

[0052] The film-forming auxiliary solvent is propylene glycol methyl ether;

[0053] 0.2 part of defoamer;

[0054] 0.5 parts of coupling agent;

[0055] Leveling agent 0.5 part;

[0056] B component:

[0057] 20 parts of water-based epoxy curing agent;

[0058] 50 parts of deionized water;

[0059] Accor...

Embodiment 2

[0062] An insulating and anti-corrosion coating for electric cables, according to the mass fraction ratio, its formula includes the following components:

[0063] A component:

[0064] 35 parts of aqueous epoxy resin emulsion;

[0065] 5 parts glass fiber;

[0066] Glass fiber diameter 10μm;

[0067] 3 parts preservative;

[0068] 0.5 part of ultraviolet fluorescent powder;

[0069] The particle size of ultraviolet fluorescent powder is 5μm, which can be developed under ultraviolet light with a wavelength of 190-400nm;

[0070] 6 parts ceramic powder;

[0071] The particle size of ceramic powder is 20μm;

[0072] 4 parts of film-forming auxiliary solvent;

[0073] Film-forming auxiliary solvent is propylene glycol methyl ether acetate;

[0074] 1.5 parts of defoamer;

[0075] 1.5 parts of coupling agent;

[0076] Leveling agent 1.5 parts;

[0077] B component:

[0078] 30 parts of water-based epoxy curing agent;

[0079] 50 parts of deionized water;

[0080] Acco...

Embodiment 3

[0083] An insulating and anti-corrosion coating for electric cables, according to the mass fraction ratio, its formula includes the following components:

[0084] A component:

[0085] 32 parts of aqueous epoxy resin emulsion;

[0086] 7 parts glass fiber;

[0087] Glass fiber diameter 15μm;

[0088] 1.5 parts of preservatives;

[0089] 0.3 parts of ultraviolet fluorescent powder;

[0090] The particle size of ultraviolet fluorescent powder is 10μm, which can be developed under ultraviolet light with a wavelength of 190-400nm;

[0091] 15 parts ceramic powder;

[0092] The particle size of ceramic powder is 15μm;

[0093] 3 parts of film-forming auxiliary solvent;

[0094] The film-forming cosolvent is 3-ethyl ether propionate;

[0095] 1.2 parts of defoamer;

[0096] 1 part of coupling agent;

[0097] Leveling agent 0.8 part;

[0098] B component:

[0099] 25 parts of water-based epoxy curing agent;

[0100] 50 parts of deionized water;

[0101] According to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com