Self-assembled nano silicon dioxide abrasive material, polishing solution containing abrasive material and application thereof

A nano-silicon dioxide, silicon dioxide technology, applied in polishing compositions containing abrasives, nanotechnology, nanotechnology and other directions, can solve the problems of reducing polishing efficiency, heavy scratches on the wafer surface, and difficulty in uniform dispersion of nanoparticles , to reduce the scratch probability, improve the surface topography, and increase the removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0042] The preparation method of self-assembled nano silica abrasive, the specific method is as follows:

[0043] Pre-preparation: Synthesis of silica nanospheres (SNS).

[0044] Firstly, 0.3g of arginine was dissolved in 200g of water, and then 40g of tetraethyl orthosilicate (TEOS) was added. The two-phase reaction was stirred in a water bath at a speed of 500 rpm, the reaction temperature was 60 ° C, and the reaction was performed for 24 hours to obtain spherical silica abrasives with a particle size range of 50-80 nm;

[0045] Step 1: Synthesis of silica nanosphere (SNS) seed solution.

[0046]Take out 100g of pre-prepared spherical silica, add water (300g), arginine (0.48g) and F127 (PEO-PPO-PEO triblock copolymer, 5.5g) in sequence, and add 40g of TEOS. The reaction was stirred in a water bath at 60° C. for 24 h, and the obtained blue transparent liquid was a silica (SNS) seed solution.

[0047] Step 2: Through further growth of the seeds, seed meal is prepared.

[0...

Embodiment 1

[0051] A polishing liquid based on self-assembled nano silicon dioxide abrasives, in parts by weight, comprising:

[0052] Self-assembled nano-silica (through the pre-preparation in Preparation Example 1, step 1, step 2, the final non-smooth self-assembled nano-silica abrasive prepared): 20 parts;

[0053] Dispersant: 0.1 parts of polymethyl acrylate (molecular weight: 40,000);

[0054] Metal ion scavenger: 0.1 parts of sodium ethylenediamine di-o-phenylacetate (EDDHA-Na);

[0055] Surfactant: 0.5 part of polyoxyethylene alkylamine;

[0056] pH regulator: 1 part of triethanolamine;

[0057] Deionized water: 78.3 parts.

[0058] Preparation method of polishing liquid:

[0059] 1) Weigh 78.3 parts of deionized water according to the formula components;

[0060] 2) Add 20 parts of self-assembled nano-silica abrasives to deionized water, and stir at 150rpm for 10min;

[0061] 3) Add 1 part of triethanolamine to the above 2), and stir at 200rpm for 10min;

[0062] 4) Add 0.1...

Embodiment 2-19、 comparative example 1-5

[0066] Table 1 shows the components and mass contents of the polishing fluids of Examples 2-19 of the present invention and Comparative Examples 1-5.

[0067] The preparation method of polishing liquid is the same as embodiment 1.

[0068] Table 1 embodiment 2-19 and comparative example 1-5

[0069]

[0070]

[0071]

[0072]

[0073] The spherical silica abrasives in Comparative Examples 1-3 are the pre-prepared spherical silica abrasives in Preparation Example 1.

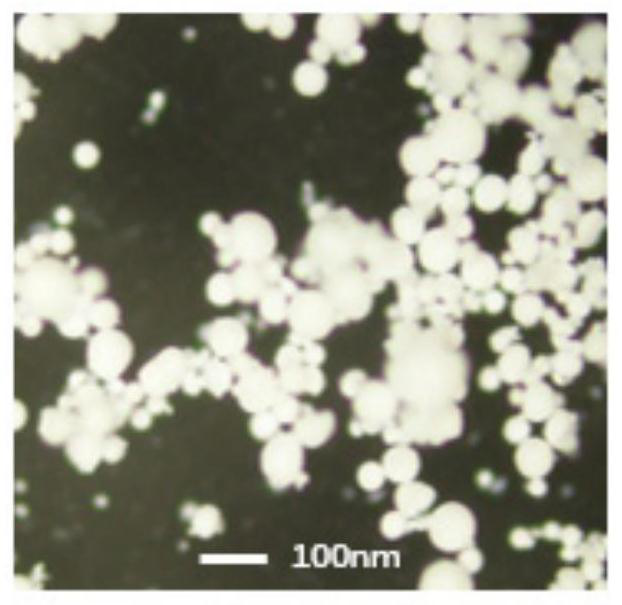

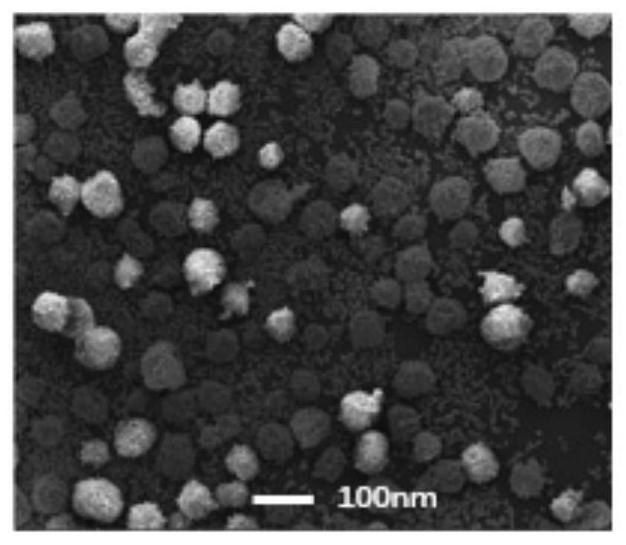

[0074] like figure 1 Shown is the scanning electron microscope picture of the spherical silica abrasive synthesized in the pre-preparation step of Comparative Example 1-3. It can be seen from the figure that the pre-preparation method successfully synthesized spherical silica abrasive with uniform size.

[0075] The above-mentioned embodiments can be prepared according to the specific preparation steps of the above-mentioned polishing liquid.

[0076] The polishing experimental parameters of perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com