Zinc-containing solid waste treatment method and system

A treatment method and technology for a treatment system are applied in the field of zinc-containing solid waste treatment methods and systems, and can solve the problems of impurity chlorine affecting production, high cost, and low recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

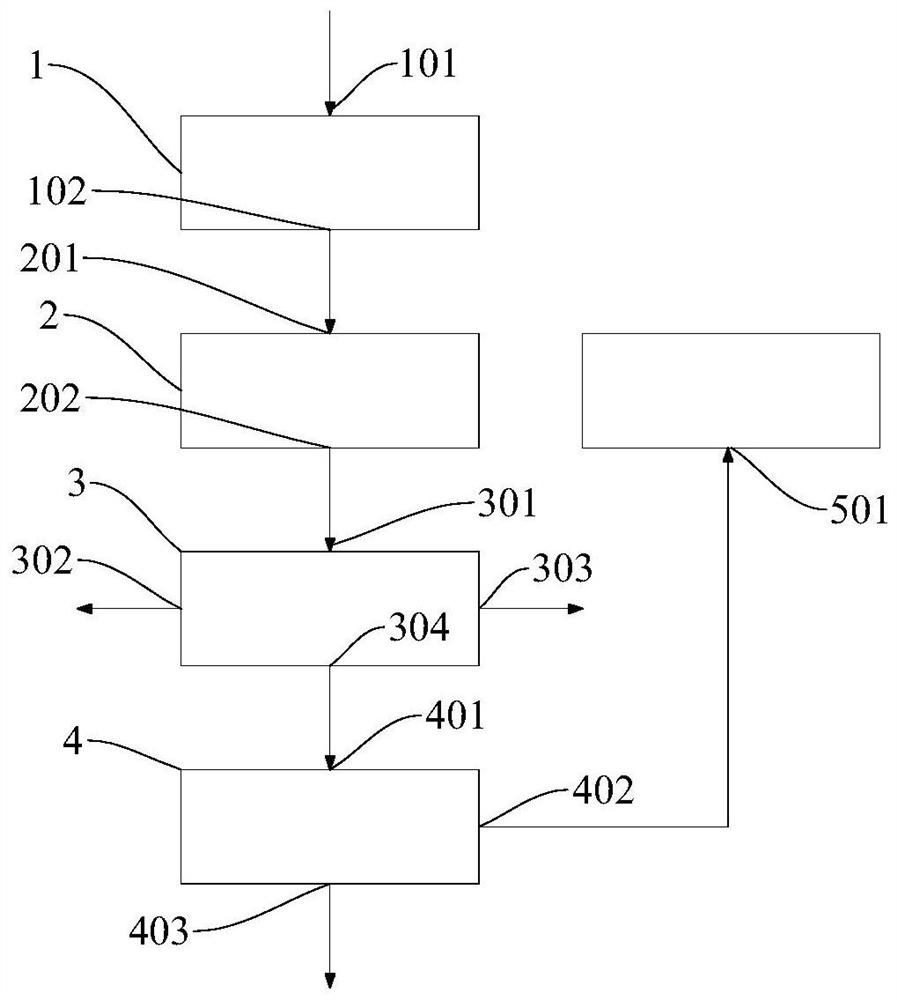

Image

Examples

Embodiment 1

[0074] The type of zinc-containing solid waste is conventional zinc leaching slag, and the mass ratio of zinc-containing solid waste, flux and reducing agent is 100:0:2.

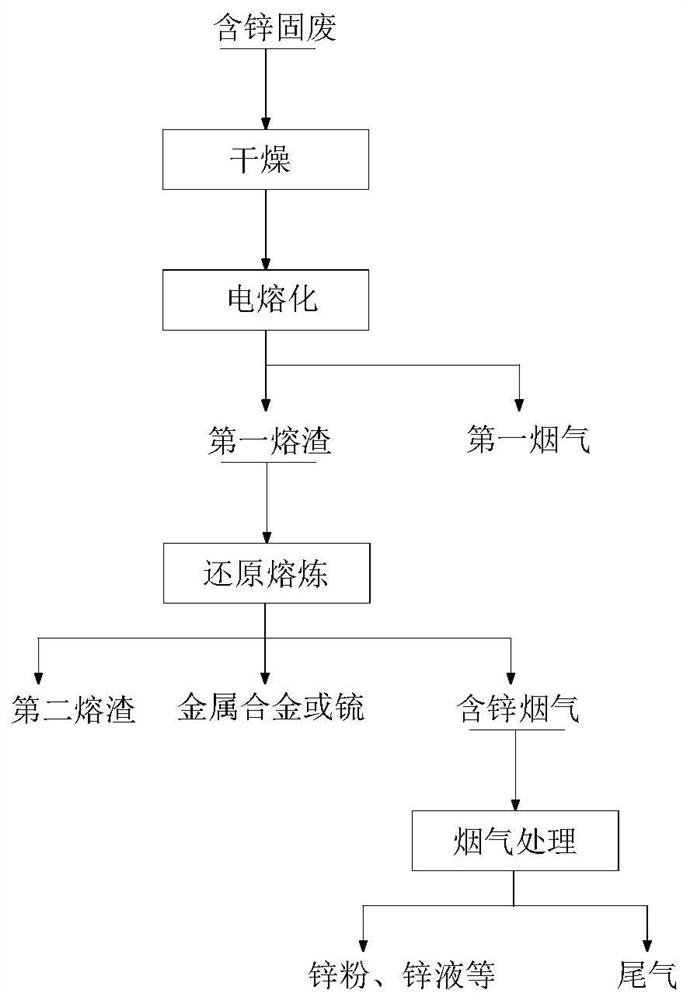

[0075] Drying the zinc-containing solid waste, flux and reducing agent, the moisture content of the dried zinc-containing solid waste, flux and reducing agent is 1%, and melting the dried zinc-containing solid waste, flux and reducing agent to obtain For high-temperature melt, coke is added in the reduction furnace 3 to reduce and smelt the first slag. The temperature of the reduction smelting is 1200°C, and the reduction time is 2 hours to obtain ferroalloy and zinc-containing flue gas, and then the zinc-containing flue gas enters the zinc powder condenser Get Zinc Dust.

Embodiment 2

[0077] The method of embodiment 2 is the same as that of embodiment 1, except that the mass ratio of zinc-containing solid waste, flux and reducing agent is 100:1:5.

[0078] The zinc-containing solid waste, flux and reducing agent are dried, and the moisture content of the dried zinc-containing solid waste, flux and reducing agent is 1%, and the dried zinc-containing solid waste, flux and reducing agent are smelted to obtain high temperature Melt, add anthracite in the reduction furnace 3 to carry out reduction smelting of the first slag, the temperature of reduction smelting is 1300 ℃, and the reduction time is 3h to obtain ferroalloy and zinc-containing flue gas, and then the zinc-containing flue gas enters the zinc rain condenser to obtain zinc liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com