Microcystic toxin ratio fluorescence sensor constructed based on molecular imprinting technology

A molecular imprinting technology, a technology of microcystins, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problem of low sensitivity of high performance liquid chromatography and can not meet the rapid monitoring of algal blooms. Timely analysis and other problems, to achieve the effect of good fluorescence response, meet the needs of rapid detection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A microcystin ratiometric fluorescent sensor based on molecular imprinting technology, the preparation method is as follows:

[0034] The first step: Synthesis of fluorescent carbon dots CQDS: Dissolve 0.3g of anhydrous citric acid in 10mL of N-(β-aminoethyl)-γ-aminopropyl-methyldimethoxysilane, and fill 50mL of Teflon Long-lined stainless steel autoclave, and degassed with nitrogen for 20 minutes; then, the autoclave was kept at 240 ° C for 2 hours, cooled to room temperature; the solution was filtered with a filter membrane; then washed three times with petroleum ether, and the obtained The product was dispersed in absolute ethanol to obtain a fluorescent carbon dot CQDS ethanol solution, and stored in a refrigerator at 4°C for further use;

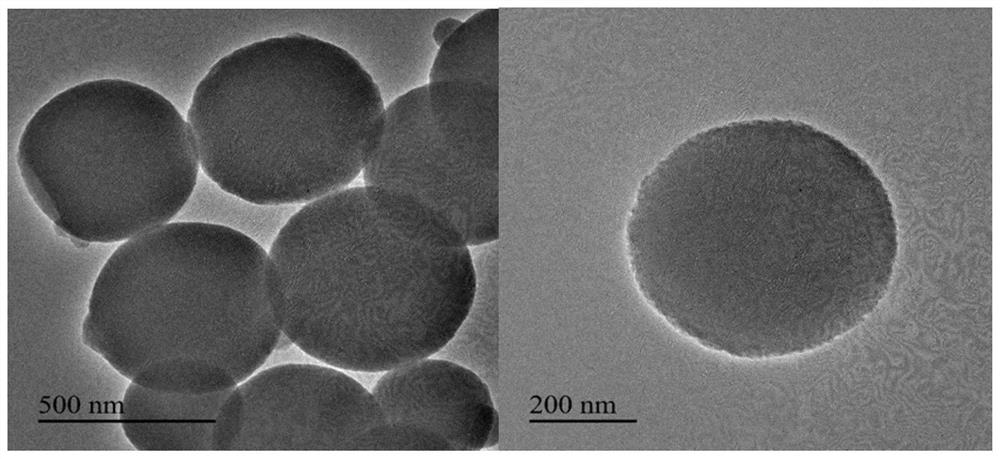

[0035] Step 2: FITC-APTES-SiO 2 Preparation of composite nanoparticles: Mix 4mg FITC with 10mL water, stir evenly with magnetic force at room temperature, add 100μL 3-aminopropyltriethoxysilane APTES, and stir at constant temper...

Embodiment 2

[0039] A microcystin ratiometric fluorescent sensor based on molecular imprinting technology, the preparation method is as follows:

[0040] Step 1: Synthesis of fluorescent carbon dots CQDS: Dissolve 0.6g of anhydrous citric acid in 10mL of N-(β-aminoethyl)-γ-aminopropyl-methyldimethoxysilane, and fill in 50mL of Teflon Long-lined stainless steel autoclave, and degassed with nitrogen for 20 minutes; then, the autoclave was kept at 240 ° C for 2 hours, cooled to room temperature; the solution was filtered with a filter membrane; then washed three times with petroleum ether, and the obtained The product was dispersed in absolute ethanol to obtain a fluorescent carbon dot CQDS ethanol solution, and stored in a refrigerator at 4°C for further use;

[0041] Step 2: FITC-APTES-SiO 2 Preparation of composite nanoparticles: Mix 4-10 mg of FITC with 10 mL of water, stir evenly with magnetic force at room temperature, add 100 μL of 3-aminopropyltriethoxysilane APTES, and stir at const...

Embodiment 3

[0045] A microcystin ratiometric fluorescent sensor based on molecular imprinting technology, the preparation method is as follows:

[0046] The first step: Synthesis of fluorescent carbon dots CQDS: Dissolve 0.5g of anhydrous citric acid in 10mL of N-(β-aminoethyl)-γ-aminopropyl-methyldimethoxysilane, and fill 50mL of Teflon Long-lined stainless steel autoclave, and degassed with nitrogen for 20 minutes; then, the autoclave was kept at 240 ° C for 2 hours, cooled to room temperature; the solution was filtered with a filter membrane; then washed three times with petroleum ether, and the obtained The product was dispersed in absolute ethanol to obtain a fluorescent carbon dot CQDS ethanol solution, and stored in a refrigerator at 4°C for further use;

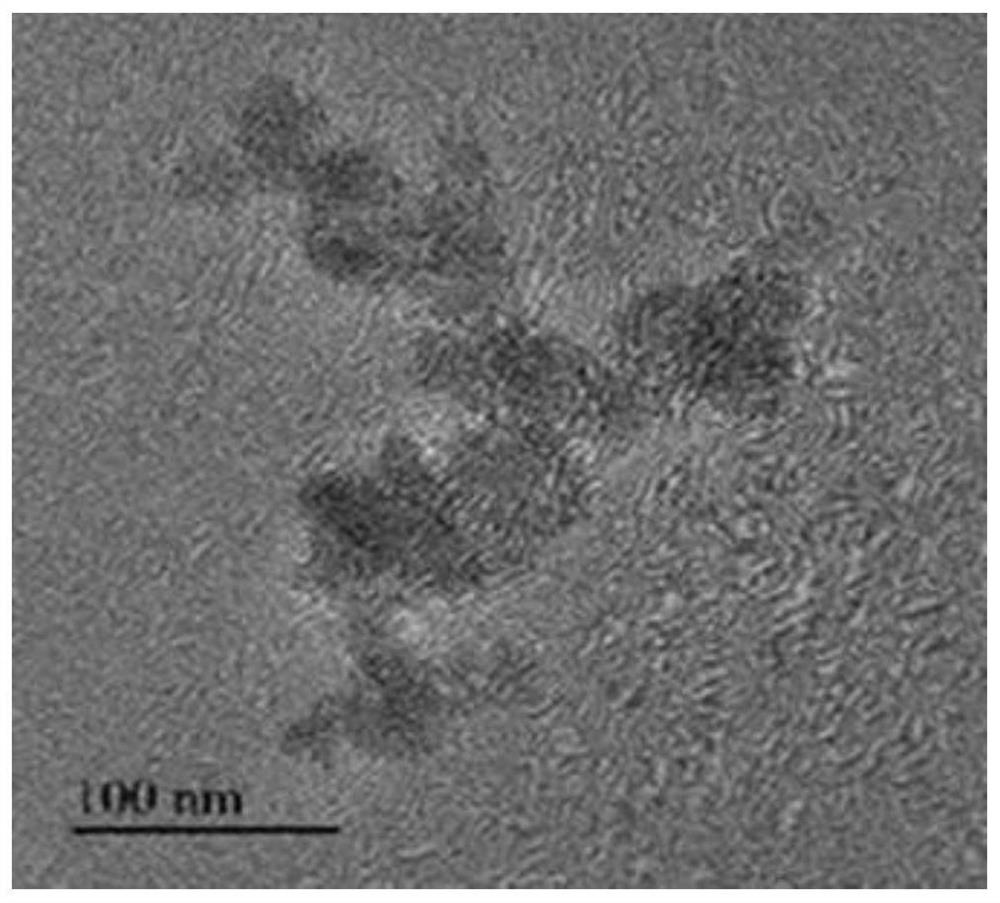

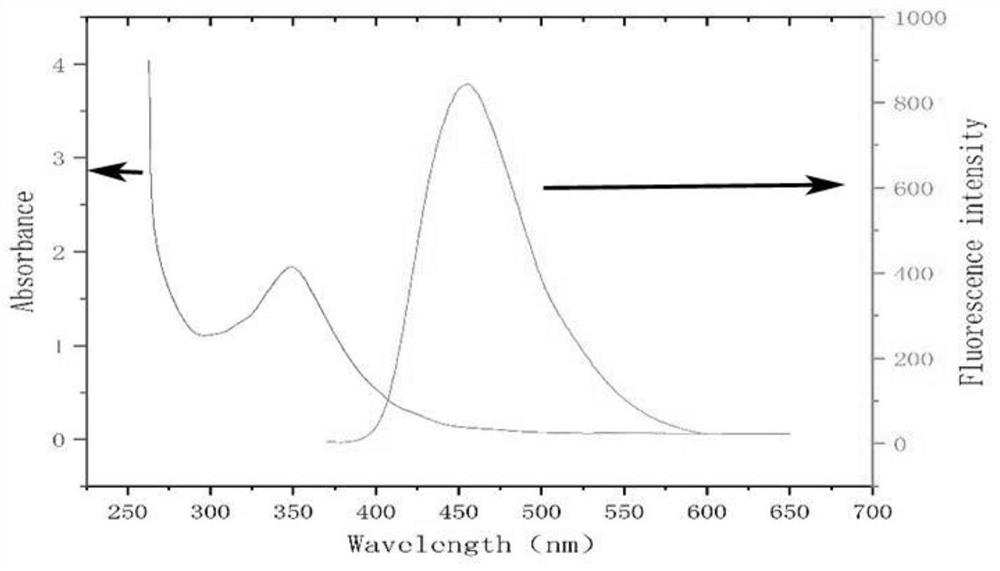

[0047] The transmission electron microscope picture of the obtained fluorescent carbon dot CQDS is as follows figure 1 shown.

[0048] The synthesis products of carbon dots include the decomposition and pyrolysis of anhydrous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com