A kind of fluffy carbon-coated silicon composite material and its preparation method and application

A silicon composite material, carbon coating technology, applied in carbon preparation/purification, nanotechnology for materials and surface science, silicon, etc., can solve problems such as electrode failure, achieve low residual carbon rate, and achieve commercialization , The effect of stable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a fluffy carbon-coated silicon composite material, the specific steps are as follows:

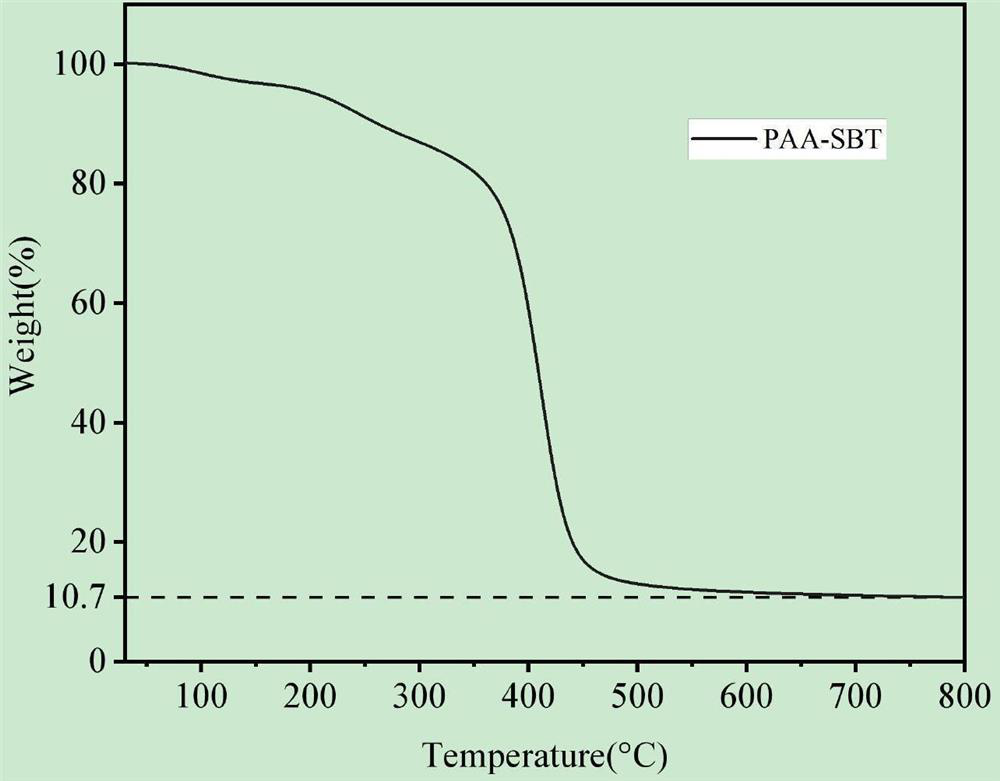

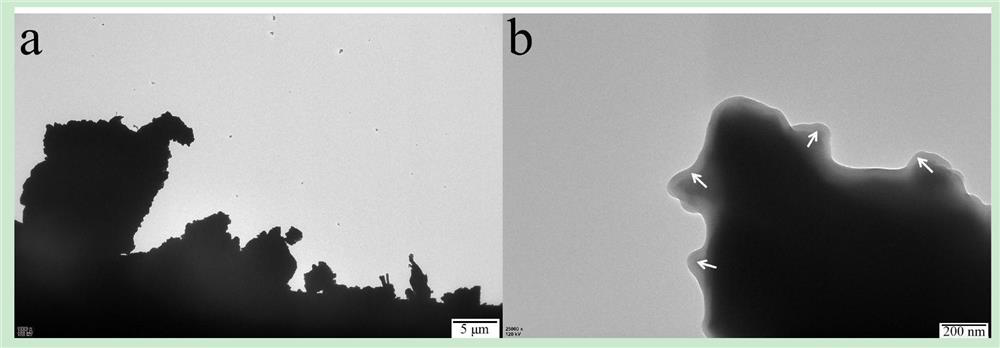

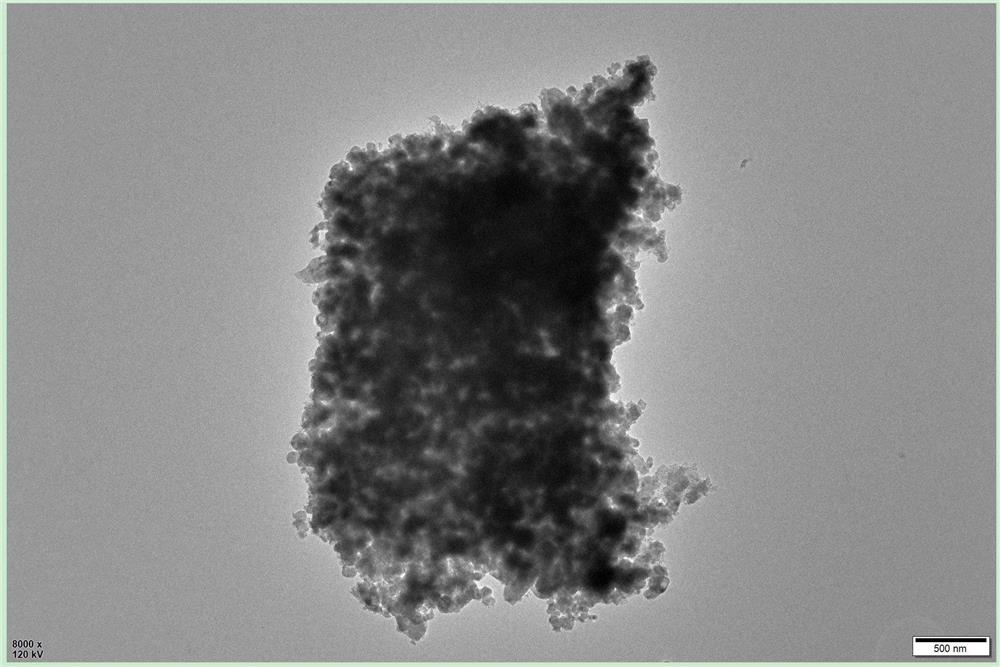

[0034] 100 mg of polyacrylic acid and 66.7 mg of sorbitol were dissolved in a mixed solution consisting of 5 mL of water and 15 mL of ethanol. 200 mg of silicon particles with a particle size of 100 nm were added to the above solution, then stirred for 5 min, sonicated for 30 min, and then placed in a water bath at 80° C. to remove the solvent. After removing the solvent, the material was ground for 10 minutes, placed in an inert atmosphere, heated to 150°C at a heating rate of 5°C / min and kept for 4 hours, and then taken out and ground for 15 minutes after the temperature dropped to <50°C. Disperse 60 mg of the ground powder in 10 mL of ethanol, and then add 100 mg of phenolic resin. The mixture was stirred for 5 min and then sonicated for 10 min, and then placed in a water bath at 80° C. to evaporate the ethanol. After removing the ethanol, the material wa...

Embodiment 2

[0038] A preparation method of a silicon carbon hollow core-shell structure composite material, the specific steps are as follows:

[0039] 200 mg of polyacrylic acid and 133.3 mg of sorbitol were dissolved in a mixed solution consisting of 5 mL of water and 15 mL of ethanol. 200 mg of silicon particles with a particle size of 100 nm were added to the above solution, then stirred for 5 min, sonicated for 30 min, and then placed in a water bath at 80° C. to remove the solvent. After removing the solvent, the material was ground for 10 minutes, placed in an inert atmosphere, heated to 200°C at a heating rate of 5°C / min and kept for 3 hours, then taken out and ground for 15 minutes after the temperature dropped to <50°C. Disperse 60 mg of the ground powder in 10 mL of ethanol, and then add 100 mg of phenolic resin. The mixture was stirred for 5 min and then sonicated for 10 min, and then spread on a polyethylene film at 50° C. to evaporate the ethanol. Since polyethylene will b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com