Electrothermal material based on strong coupling of bismuth sulfide and carbon nanotubes and preparation method thereof

A carbon nanotube, electrothermal material technology, applied in chemical instruments and methods, heating element materials, bismuth compounds, etc., can solve problems such as unfavorable large-scale production, poor mechanical properties, high price, etc. The effect of electrical conductivity and strong electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing an electrothermal material based on strong coupling between bismuth sulfide and carbon nanotubes, comprising the following steps:

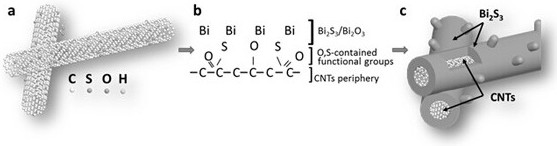

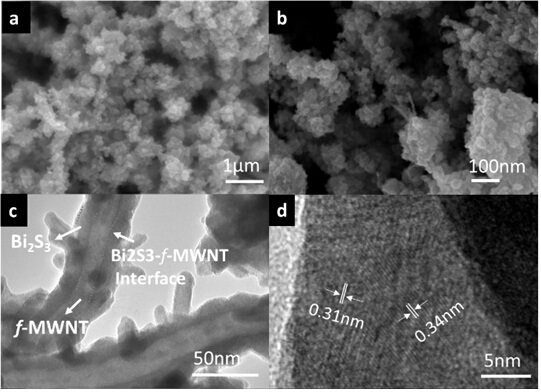

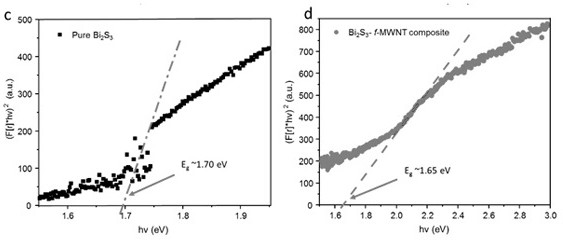

[0039]S1. Dissolve 0.51g of thioacetamide in 160ml of deionized water at room temperature, stir until completely dissolved, then add 10mg of carboxylated carbon nanotubes, and ultrasonically treat for 2 hours to obtain an intermediate reaction solution, carboxylated carbon nanotubes are carboxylated Multi-walled carbon nanotubes, the carboxylated multi-walled carbon nanotubes in this embodiment can be "Xianfeng XFM09 carboxylated multi-walled carbon nanotubes (length) 8-15 nm";

[0040] S2. Configure 0.4M HNO 3 solution, 1.584 g of bismuth nitrate pentahydrate was dissolved in 0.4 M HNO 3 20ml aqueous solution, and the above-mentioned nitric acid solution of bismuth nitrate pentahydrate was added dropwise to the intermediate reaction solution at a constant speed of 10 drops per minute, and continuously magnetically s...

Embodiment 2

[0044] A method for preparing an electrothermal material based on strong coupling between bismuth sulfide and carbon nanotubes, comprising the following steps:

[0045] S1. Dissolve 0.12g of thioacetamide in 160ml of deionized water at room temperature, stir at 15°C until completely dissolved, then add 10mg of carboxylated carbon nanotubes, and perform ultrasonic treatment for 2 hours to obtain an intermediate reaction solution, the carboxyl group in this example The carbonized carbon nanotubes can be "Xianfeng XFS27X carbon nanotubes", and the CAS number is 1333-86-4;

[0046] S2. Configure 0.4M HNO 3 solution, 84.9 mg of bismuth nitrate pentahydrate was dissolved in 0.3 M HNO 3 20ml aqueous solution, and the above-mentioned nitric acid solution of bismuth nitrate pentahydrate was added dropwise to the intermediate reaction solution at a constant speed of 8 drops per minute, and continuously magnetically stirred at 1000 rpm at 15°C for 6 hours to obtain a mixed solution ; ...

Embodiment 3

[0050] A method for preparing an electrothermal material based on strong coupling between bismuth sulfide and carbon nanotubes, comprising the following steps:

[0051] S1. Dissolve 0.3g of thioacetamide in 160ml of deionized water at room temperature, stir at 15°C until completely dissolved, then add 10mg of carboxylated carbon nanotubes, and perform ultrasonic treatment for 2 hours to obtain an intermediate reaction solution, the carboxyl group in this example The carbonized carbon nanotubes can be "Xianfeng XFS27X carbon nanotubes", and the CAS number is 1333-86-4;

[0052] S2. Configure 0.4M HNO 3 solution, 1.584 g bismuth nitrate pentahydrate was dissolved in 0.5 M HNO 3 20ml aqueous solution, and the above-mentioned nitric acid solution of bismuth nitrate pentahydrate was added dropwise to the intermediate reaction solution at a constant speed of 12 drops per minute, and continuously magnetically stirred at 800 rpm at 25°C for 24 hours to obtain a mixed solution ;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power factor | aaaaa | aaaaa |

| Power factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com