High performance liquid chromatography detection method of sodium allysulfonate

A technology of sodium allyl sulfonate and high performance liquid chromatography, applied in the field of analytical chemistry, can solve the problems such as the reaction of sodium allyl sulfonate chromogen and the interference of quantitative detection of sodium allyl sulfonate, and achieve detection The method is simple and easy to implement, and the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

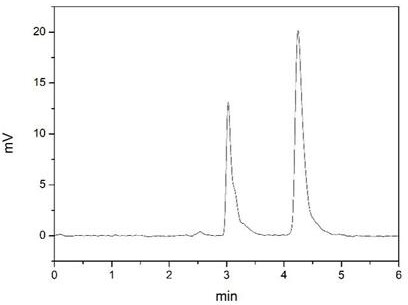

[0030] (1) Dilute the water sample containing allyl sodium sulfonate to volume with deionized water, and then perform high-performance liquid chromatography detection to obtain the chromatographic peak area of allyl sodium sulfonate; the chromatographic conditions are as follows:

[0031] Chromatographic column: C18 (4.6mm×300mm, 5μm); column temperature: 25°C; injection volume: 20μL; flow rate: 1.0mL / min; mobile phase: A is methanol, B is 0.02mol / L ammonium acetate solution, A :B=2:98; evaporative photodetector drift tube 95°C, carrier gas flow rate 3.5L / min.

[0032] (2) According to the standard curve of allyl sodium sulfonate y=2.1394x-3.8556 (x is the mass concentration of allyl sodium sulfonate, y is the chromatographic peak area of allyl sodium sulfonate), combined with allyl The chromatographic peak area of sodium sulfonate obtains the content of allyl sodium sulfonate, and the allyl sodium sulfonate content is 58.50mg / L in this sample.

Embodiment 2

[0034] Except that the water sample to be tested containing allyl sodium sulfonate is different, all the other steps are the same as in Example 1, and the content of allyl sodium sulfonate in the sample obtained by HPLC analysis is 72.63mg / L.

Embodiment 3

[0036] Except that the water sample to be tested containing allyl sodium sulfonate is different, all the other steps are the same as in Example 1, and the content of allyl sodium sulfonate in the sample obtained by HPLC analysis is 32.60 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com