Method for preparing catalyst through polymer-metal complex assisted carbonization MOF technology and obtained catalyst

A technology of metal complexes and catalysts, which is applied in the field of preparation of catalysts by polymer-metal complexes assisted carbonization MOF technology, can solve the problems of performance gap and reduce the utilization rate of Fe source, achieve excellent performance, and suppress the inactive metal particles The effect of simple formation and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

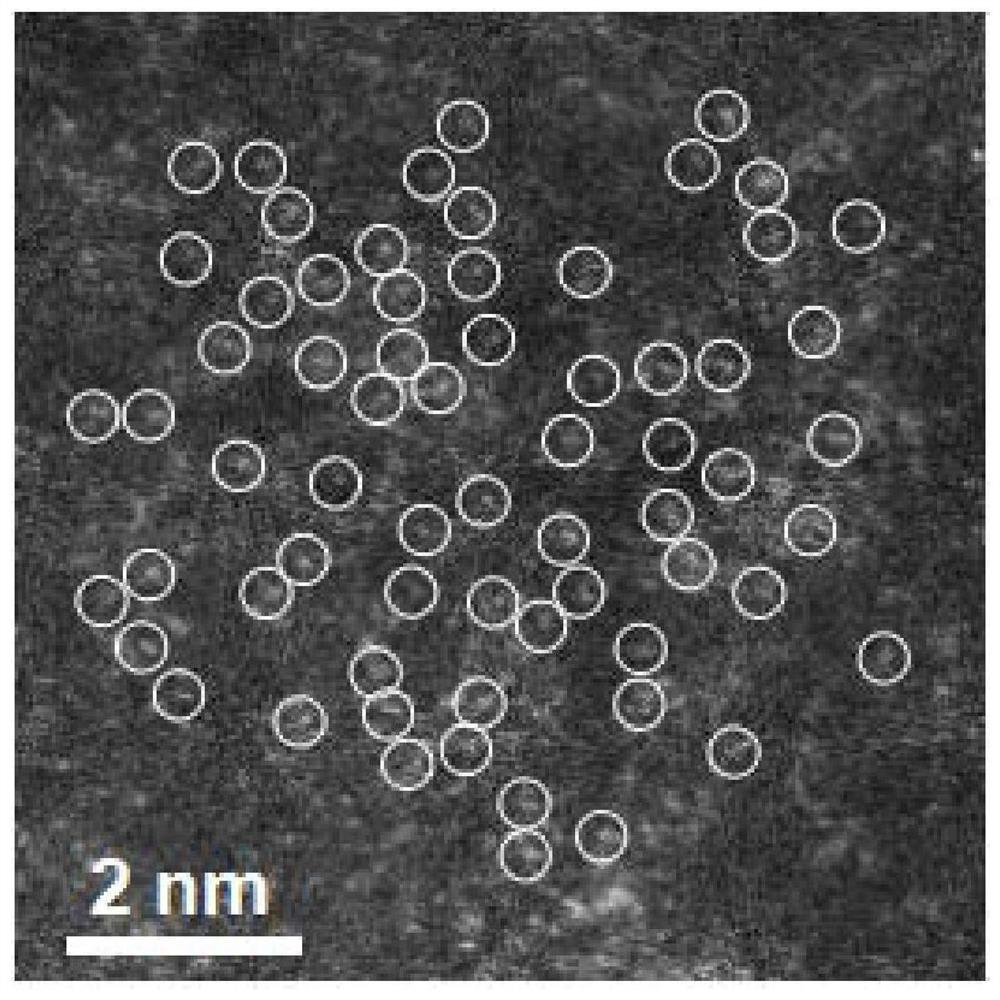

[0035] Example 1 High Exposure Dense FeN 4 Preparation of highly active Fe-N / C catalysts at sites

[0036] A kind of preparation method of Fe-N / C catalyst, comprises the steps:

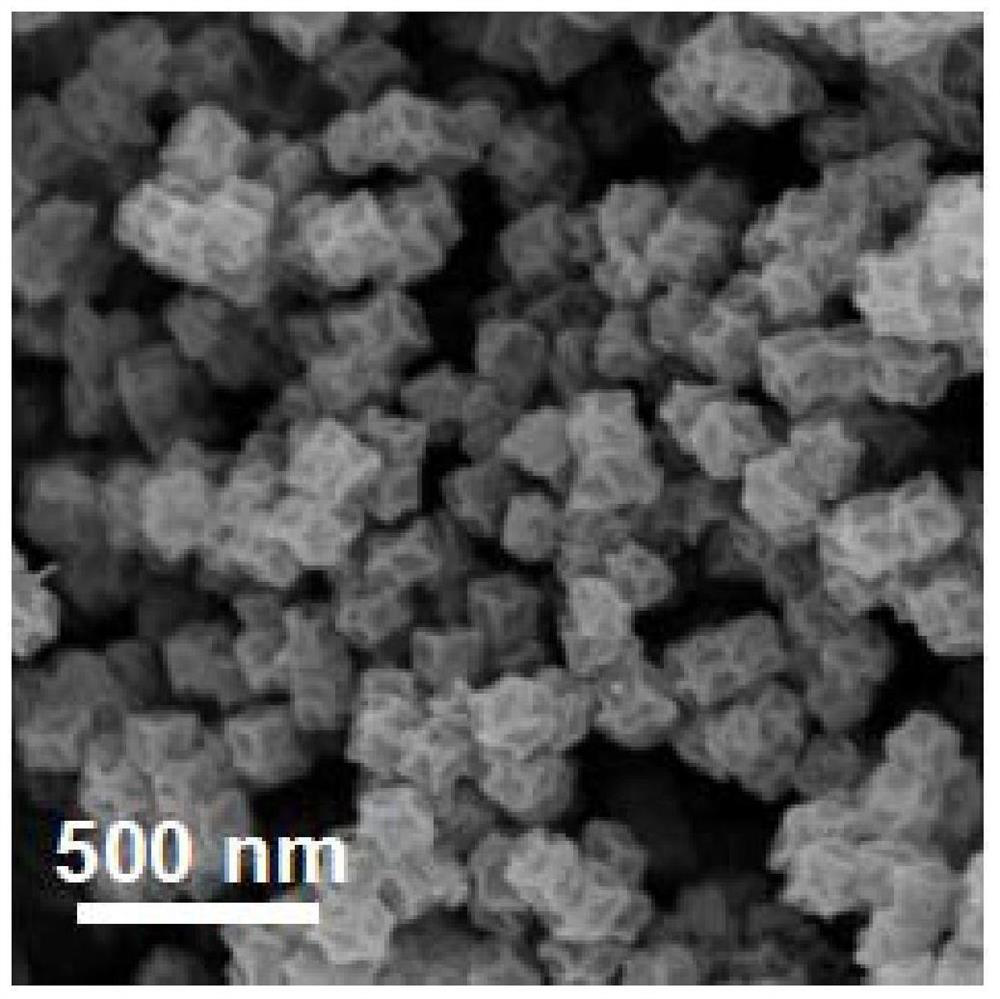

[0037] (1) 50mL containing 2.23g Zn(NO 3 ) 2 ·6H 2 The methanol solution of O was quickly added to 50 mL of methanol solution containing 2.46 g of 2-methylimidazole, stirred vigorously at room temperature for 5 hours, and the precipitate was obtained by high-speed centrifugation, washed with methanol for three times, and finally vacuum-dried at 60°C to obtain ZIF-8 nanoparticles.

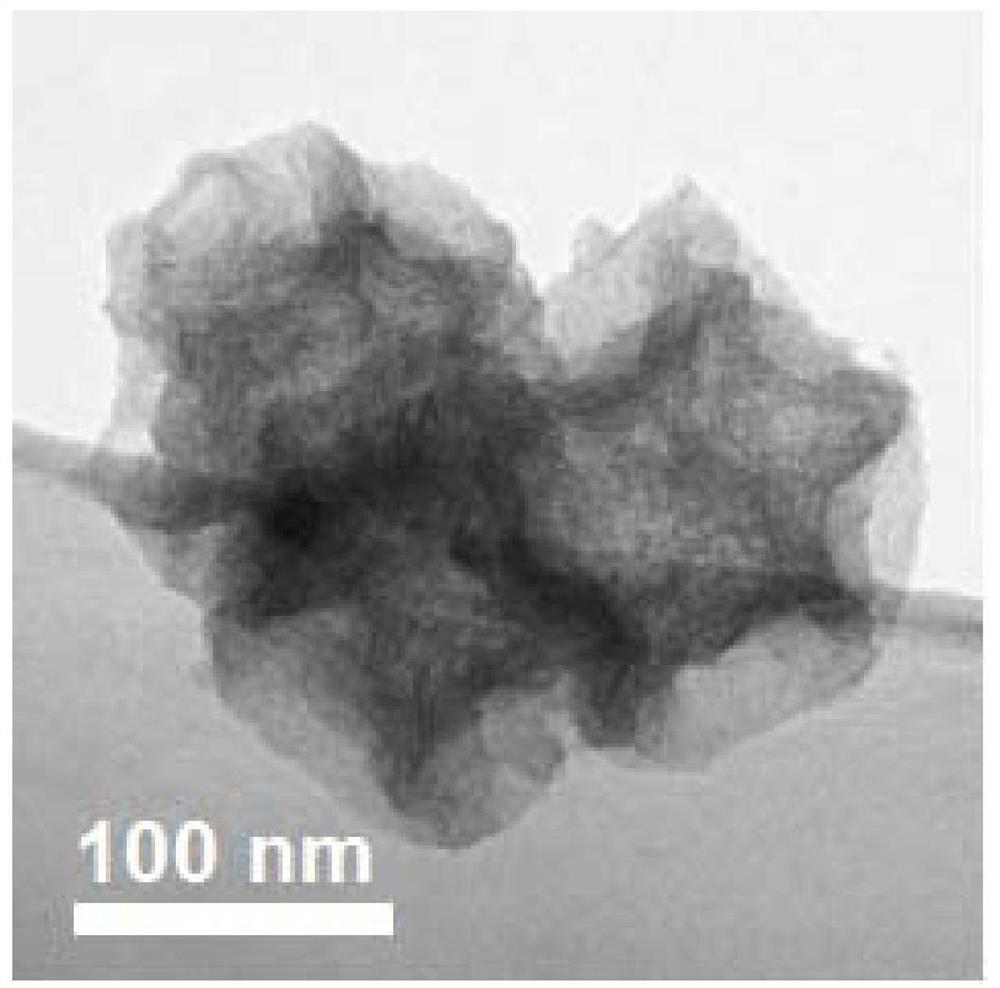

[0038] (2) 200mg ZIF-8 nanoparticles are dispersed in the mixed solution of 30ml water and 30ml ethanol, after ultrasonic 2h, add 15mg dopamine hydrochloride monomer and 12mg poloxamer F127 (Pluronic F127) and stir to obtain dispersion liquid; Add 0.6ml dropwise to the dispersion to make the concentration 50mg ml -1 [Fe(Phen) 3 ] 2+ Ethanol solution, stirred for 30 minutes, added ammonia water to adjust the pH to 8....

Embodiment 2

[0046] Example 2 High Exposure Dense CoN 4 Preparation of highly active Co-N / C catalysts at sites

[0047] A kind of preparation method of highly active Co-N / C catalyst, comprises the steps:

[0048] (1) 50mL containing 2.23g Zn(NO 3 ) 2 ·6H 2 The methanol solution of O was quickly added to 50 mL of methanol solution containing 2.46 g of 2-methylimidazole, stirred vigorously at room temperature for 5 hours, and the precipitate was obtained by high-speed centrifugation, washed with methanol for three times, and finally vacuum-dried at 60°C to obtain ZIF-8 nanoparticles.

[0049] (2) Disperse 200mg of ZIF-8 nanoparticles in a mixture of 30ml of water and 30ml of ethanol. After ultrasonication for 2 hours, add 15mg of dopamine hydrochloride monomer and 12mg of Pluronic F127, and stir to obtain a dispersion; then dropwise add 0.6 ml concentration is 50mg ml -1 [Co(Phen) 3 ] 2+ Ethanol solution, stirred for 30 minutes, added ammonia water to adjust the pH to 8.5, exposed to...

Embodiment 3

[0052] Example 3 High Exposure Dense NiN 4 Preparation of highly active Ni-N / C catalysts at sites

[0053] A kind of preparation method of highly active Ni-N / C catalyst, comprises the steps:

[0054] (1) 50mL containing 2.23g Zn(NO 3 ) 2 ·6H 2 The methanol solution of O was quickly added to 50 mL of methanol solution containing 2.46 g of 2-methylimidazole, stirred vigorously at room temperature for 5 hours, and the precipitate was obtained by high-speed centrifugation, washed with methanol for three times, and finally vacuum-dried at 60°C to obtain ZIF-8 nanoparticles.

[0055] (2) Disperse 200mg of ZIF-8 nanoparticles in a mixture of 30ml of water and 30ml of ethanol. After ultrasonication for 2 hours, add 15mg of dopamine hydrochloride monomer and 12mg of Pluronic F127, and stir to obtain a dispersion; then dropwise add 0.6ml concentration is 50mg ml -1 [Ni(Phen) 3 ] 2+ Ethanol solution, stirred for 30 minutes, added ammonia water to adjust the pH to 8.5, exposed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| half wave potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com