Spinning solution for fuel cell and preparation method of carbon paper of spinning solution

A fuel cell and spinning solution technology, which is applied in the fields of fuel cells, battery electrodes, rayon manufacturing, etc., can solve the problems of high consistency requirements, difficult to disperse evenly, affecting mass transfer, etc., and achieve a simple and controllable preparation process. , cost reduction, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of carbon paper for fuel cells specifically comprises the following steps:

[0037] Step 1, adding 20% polyacrylonitrile, 72% dimethylformamide and dimethyl sulfoxide, 5% dimethyl phthalate and diethyl phthalate to prepare spinning liquid;

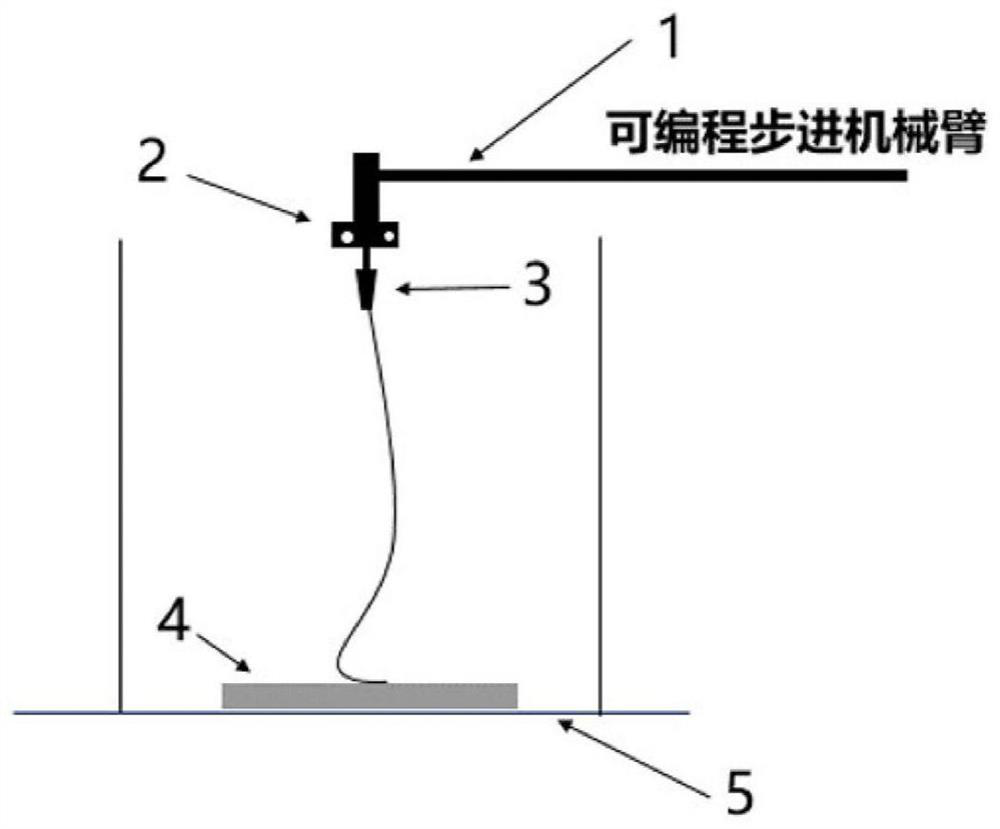

[0038] Step 2: Place the steel sheet base 4 in the injection chamber, and set the internal environment of the injection chamber 5: the injection temperature is 50°C, and the injection humidity is 30%; controlling the injection temperature and humidity is conducive to solvent volatilization, fiber formation, and carbon Stable formation of paper porous structure.

[0039] Step 3, the spinning liquid is sprayed from the spinneret 3 through the pressure pump 1 and the meter 2, and sprayed on the steel sheet to form a carbon fiber paper precursor; the discharge rate of the meter is set to 15ml / min. Select the "m"-shaped stroke of the spraying stroke, set the number of spraying layers to 10, and start spraying.

[0040] Th...

Embodiment 2

[0044] Preparation of carbon paper for fuel cells specifically comprises the following steps:

[0045]Step 1, add 25% polyacrylonitrile, 80% sulfolane, ethylene nitrate, sodium thiocyanate, 3% di-n-butyl phthalate, dioctyl phthalate to prepare spinning liquid;

[0046] Step 2. Place a copper sheet in the injection chamber and set the internal environment of the injection chamber: the injection temperature is 60°C, and the injection humidity is 60%; controlling the injection temperature and humidity is conducive to solvent volatilization, fiber formation, and carbon paper porous structure stable formation.

[0047] Step 3, the spinning liquid is sprayed from the spinneret through a pressure pump and a meter, and sprayed on the copper sheet to form a carbon fiber paper precursor; the discharge rate of the meter is set to 10ml / min. Select the "m"-shaped stroke of the spraying stroke, set the number of spraying layers to 15, and start spraying.

[0048] The pressure pump is sel...

Embodiment 3

[0052] Preparation of carbon paper for fuel cells specifically comprises the following steps:

[0053] Step 1, add 40% polyacrylonitrile, 84% sulfolane, ethylene nitrate, sodium thiocyanate, 6% dimethyl phthalate, butyl benzyl phthalate to prepare spinning liquid ;

[0054] Step 2. Place an iron sheet in the injection chamber and set the internal environment of the injection chamber: the injection temperature is 40°C, and the injection humidity is 40%; controlling the injection temperature and humidity is conducive to solvent volatilization, fiber formation, and carbon paper porous structure stable formation.

[0055] Step 3, the spinning liquid is sprayed from the spinneret through a pressure pump and a meter, and sprayed on the iron sheet to form a carbon fiber paper precursor; the discharge rate of the meter is set to 8ml / min.

[0056] Select the "m"-shaped stroke of the spraying stroke, set the number of spraying layers to 11, and start spraying.

[0057] The pressure p...

PUM

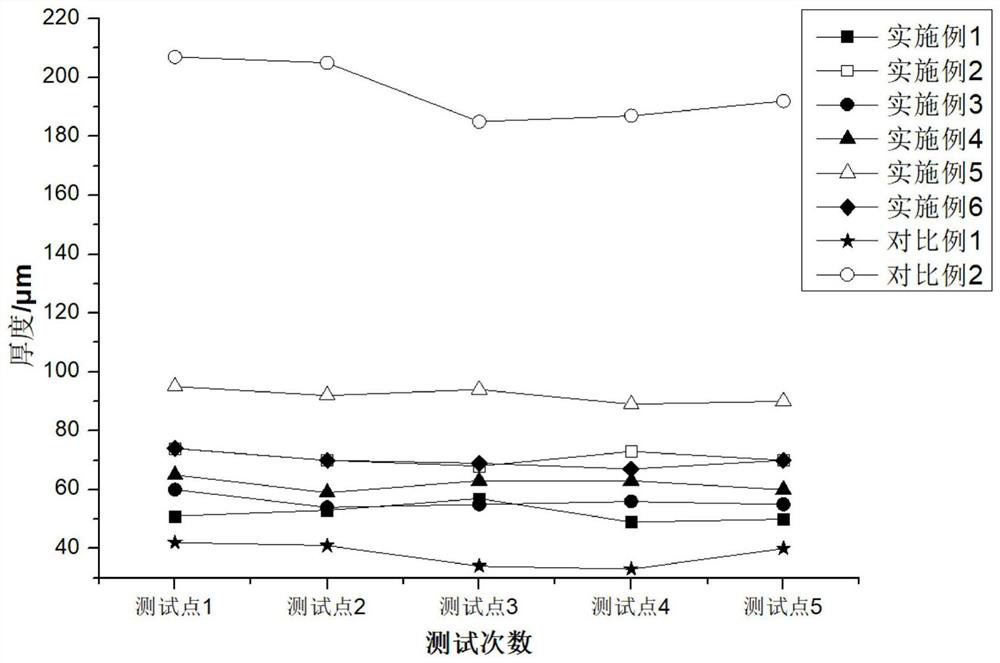

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com