Preparation method of in-situ resin-coated anti-corrosion special-shaped magnetic wave absorber powder

A magnetic wave absorber and resin coating technology, applied in anti-corrosion coatings, radiation-absorbing coatings, magnetic field/electric field shielding, etc., to achieve the effects of low price, improved corrosion resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

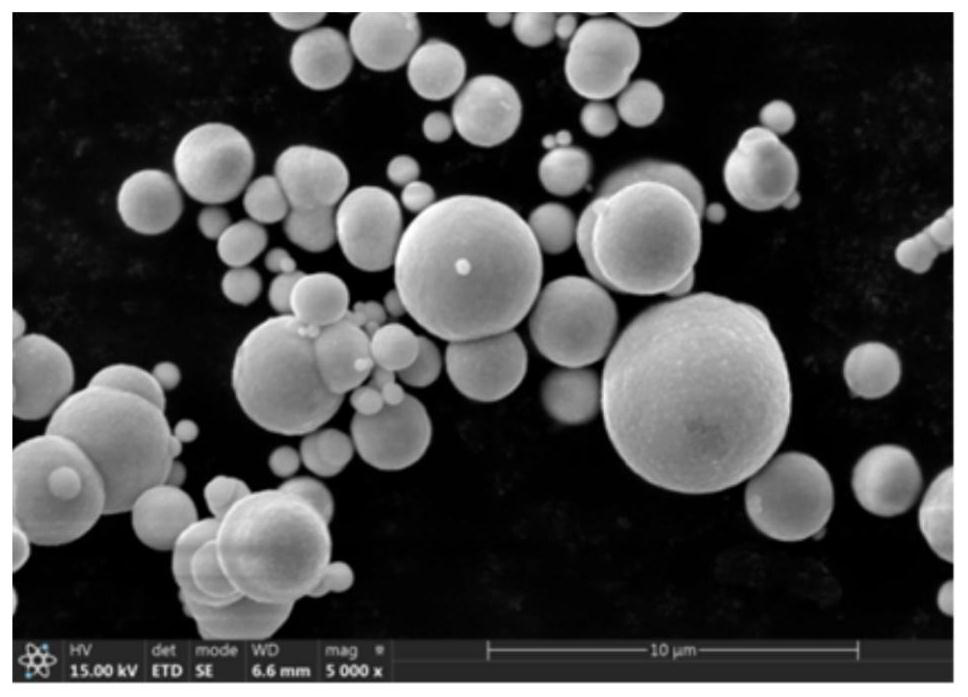

[0035] Step 1: In terms of mass, add 100 parts of absolute ethanol and 0.1 part of polyvinylpyrrolidone (PVP) K-30 to 50 parts of carbonyl iron powder, heat to 40° C., and mechanically stir for 0.5 hours. The carbonyl iron powder is a spherical carbonyl iron powder with a diameter of 1-5 μm.

[0036] Step 2: Add 4 parts of resorcinol and 4 parts of concentrated ammonia water to the mixture obtained in step 1, keep the temperature, and continue mechanical stirring for 0.5 hours. The mass fraction of ammonia in the concentrated ammonia water is 25%.

[0037] Step 3: Add 6 parts of formaldehyde aqueous solution to the mixture obtained in Step 2, keep the temperature, and continue mechanical stirring for 3 hours. The mass fraction of formaldehyde in the formaldehyde aqueous solution is 35%.

[0038] Step 4: The mixture obtained in Step 3 was subjected to solid-liquid separation by magnetic separation, washed 3 times with absolute ethanol, dried in air at 50° C. for 12 hours, and...

Embodiment 2

[0041] Step 1: In terms of mass, 160 parts of absolute ethanol and 0.25 parts of polyvinylpyrrolidone (PVP) K-30 were added to 100 parts of carbonyl iron powder, heated to 50° C., and mechanically stirred for 0.5 hours. The carbonyl iron powder is a spherical carbonyl iron powder with a diameter of 1-5 μm.

[0042] Step 2: Add 8 parts of resorcinol and 3 parts of concentrated ammonia water to the mixture obtained in step 1, keep the temperature, and continue mechanical stirring for 0.5 hours. The mass fraction of ammonia in the concentrated ammonia water is 28%.

[0043] Step 3: Add 8 parts of aqueous formaldehyde solution to the mixture obtained in Step 2, keep the temperature, and continue mechanical stirring for 3 hours. The mass fraction of formaldehyde in the formaldehyde aqueous solution is 40%.

[0044] Step 4: The mixture obtained in Step 3 was subjected to solid-liquid separation by magnetic separation, washed 3 times with absolute ethanol, dried in air at 40° C. fo...

Embodiment 3

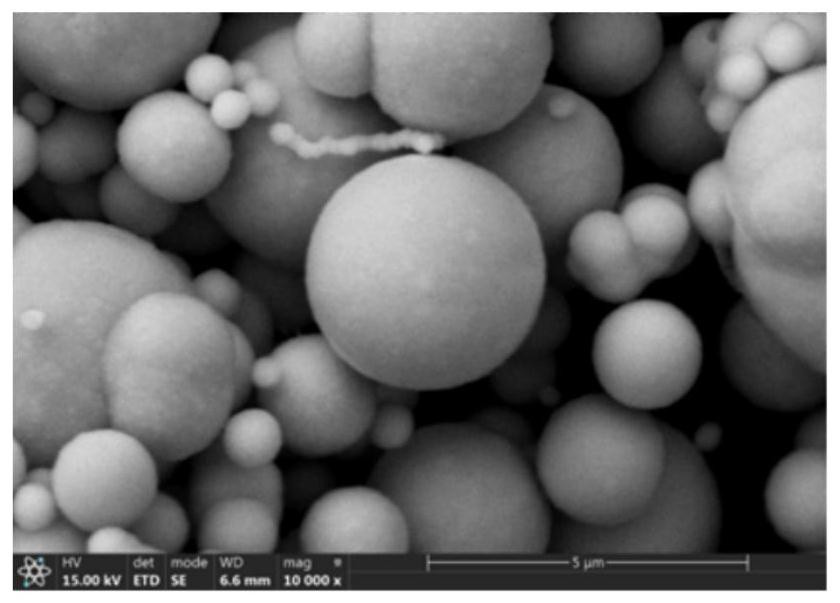

[0047] Step 1: In terms of mass, 160 parts of absolute ethanol and 0.25 parts of polyvinylpyrrolidone (PVP) K-30 were added to 100 parts of carbonyl iron powder, heated to 50° C., and mechanically stirred for 0.5 hours. The carbonyl iron powder is flake carbonyl iron powder.

[0048] Step 2: Add 1 part of resorcinol and 4 parts of concentrated ammonia water to the mixture obtained in step 1, keep the temperature, and continue mechanical stirring for 0.5 hours. The mass fraction of ammonia in the concentrated ammonia water is 26%.

[0049] Step 3: Add 1.5 parts of formaldehyde aqueous solution to the mixture obtained in Step 2, keep the temperature, and continue mechanical stirring for 3 hours. The mass fraction of formaldehyde in the formaldehyde aqueous solution is 38%.

[0050] Step 4: The mixture obtained in Step 3 was subjected to solid-liquid separation by magnetic separation, washed 3 times with absolute ethanol, dried in air at 70° C. for 12 hours, and then vacuum-dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com