Preparation method of medicine porous sustained-release body and medicine porous sustained-release body

A slow-release, drug-based technology, applied in drug combinations, pharmaceutical formulations, medical preparations with non-active ingredients, etc., can solve the problems that the position of drug diffusion cannot be effectively displayed, and the drug's action time can be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

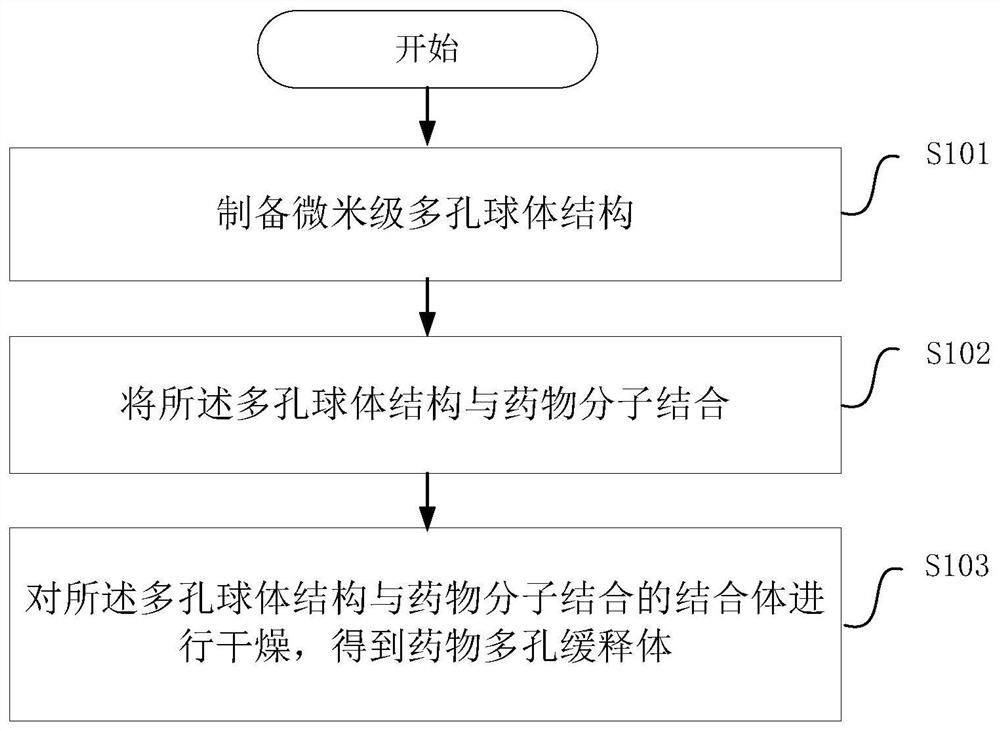

[0056] see figure 1 , the present invention claims to protect a preparation method of a drug porous sustained-release body, the method comprising:

[0057] In step S101, a micron-scale porous spherical structure is prepared. Because the molecular structure of the sphere is loose, there will be some small pores, and these small pores make the air inside the porous sphere with a relatively large difference in acoustic resistance from the surrounding tissue, which is conducive to enhancing the scattering effect of ultrasonic waves. One of polylactic acid-glycolic acid copolymer, silk fibroin or chitosan is used as the spherical material in the porous spherical structure.

[0058] Preferably, in the porous sphere structure, the diameter of the sphere is between 1 μm and 50 μm, for example: 1 μm, 25 μm or 50 μm.

[0059] In addition, according to the size and uniformity of the pore size in the porous spherical structure, the porous spherical structure in the present invention inc...

Embodiment 1

[0065] When the porous spherical structure is a uniform mesoporous spherical structure based on polylactic acid-glycolic acid copolymer material, the preparation method includes the following steps:

[0066] a1) Preparation of polylactic acid-glycolic acid porous spherical structure: add 0.3g of polylactic acid-glycolic acid and Pluronic nonionic surfactant (F127) into 6ml of dichloromethane solvent, and add 50ml of 1% polyethylene after mixing evenly The alcohol solution was stirred at low speed overnight to obtain polylactic acid-glycolic acid hollow microspheres containing surfactant.

[0067] The polylactic acid-glycolic acid hollow microspheres were processed by centrifugation. Preferably, the centrifugal speed is 3000 rpm, and the centrifugal treatment is performed for 5 min.

[0068] The polylactic-glycolic acid hollow microspheres were rinsed three times with absolute ethanol and subjected to critical point drying. The dried hollow microspheres were stored at 4°C for...

Embodiment 2

[0073] When the porous sphere structure is a uniform macroporous sphere structure based on silk fibroin material, the preparation method includes the following steps:

[0074] a2) Preparation of silk fibroin porous sphere structure:

[0075] To prepare silica microspheres:

[0076] ① Preparation of monodisperse silica nanoparticles:

[0077] Water, ethyl orthosilicate, arginine, and cyclohexane are uniformly mixed to prepare silicon dioxide nanoparticles with monodispersity and a size of 10 nm to 20 nm; the silicon dioxide nanoparticle solution is dispersed in In the seed growth reaction system constructed by ethanol and ammonia water; while stirring uniformly, slowly drop the silica precursor solution to obtain monodisperse silica particles of the desired size (such as 200 nm);

[0078] ②Preparation of silica microspheres:

[0079] The monodispersed 200nm silica nanoparticles were centrifuged and purified, and the proportion of the colloidal nanoparticles in the nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com