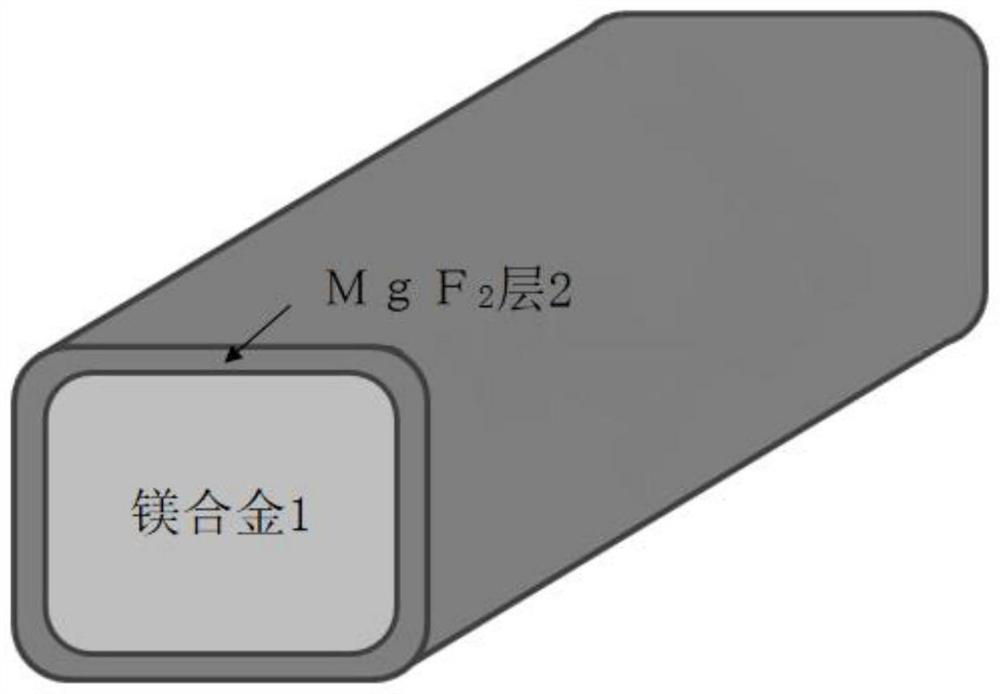

Bioabsorbable magnesium alloy stent and preparation method thereof

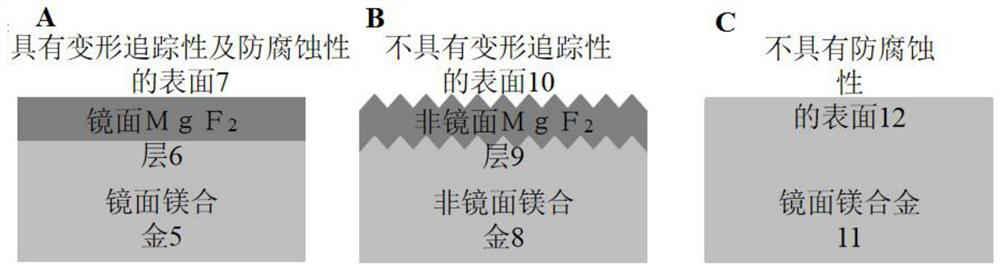

A magnesium alloy stent and magnesium alloy technology, applied in the field of bioabsorbable magnesium alloy stent and its preparation, can solve problems such as substrate damage and pitting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

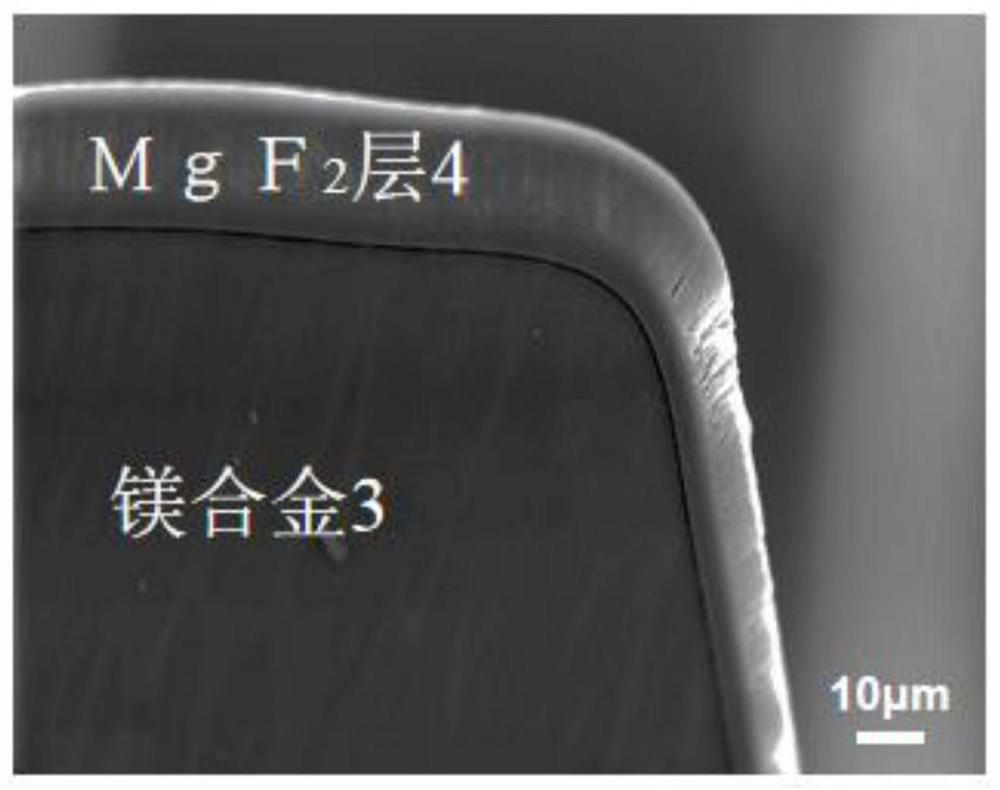

Embodiment 1

[0039]The stent body immersed in the electrolyte is placed on the anode, and the metal plate is used as the cathode, and the two are connected through a DC power supply, and the surface of the stent body of the anode is ground and processed into any size by applying an external voltage. In order to achieve the stabilization of the viscous layer in the applied voltage, the temperature was controlled at a fixed temperature while stirring the electrolyte. In addition, in order to suppress the generation of air bubbles at the cathode, appropriate voltage application and cut-off operations should be repeated. In addition, air bubbles dissociated from the cathode will cause poor surface accuracy if they adhere to the holder body. As a result, through this electrolytic polishing, an outer diameter of 1.8 mm, a length of 18 mm, a thickness of 120 μm, and a surface area of 103.8 mm were fabricated. 2 , Weight 5mg, Ra0.04±0.01μm core structure. In addition, the Ra of the stent body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com