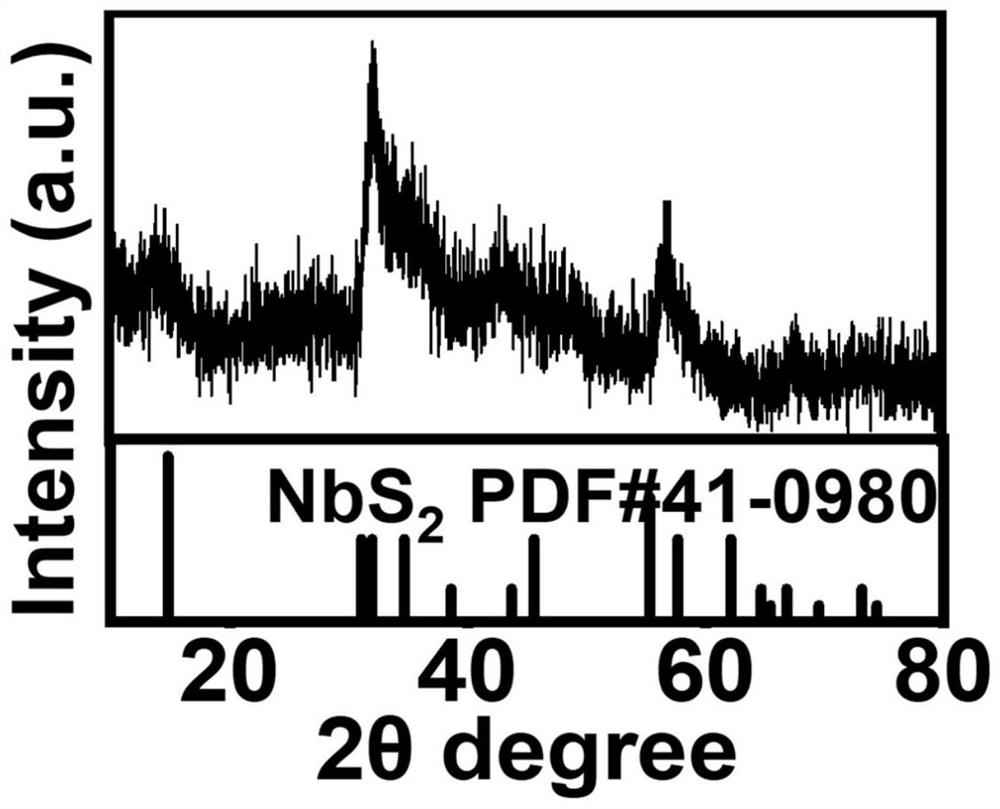

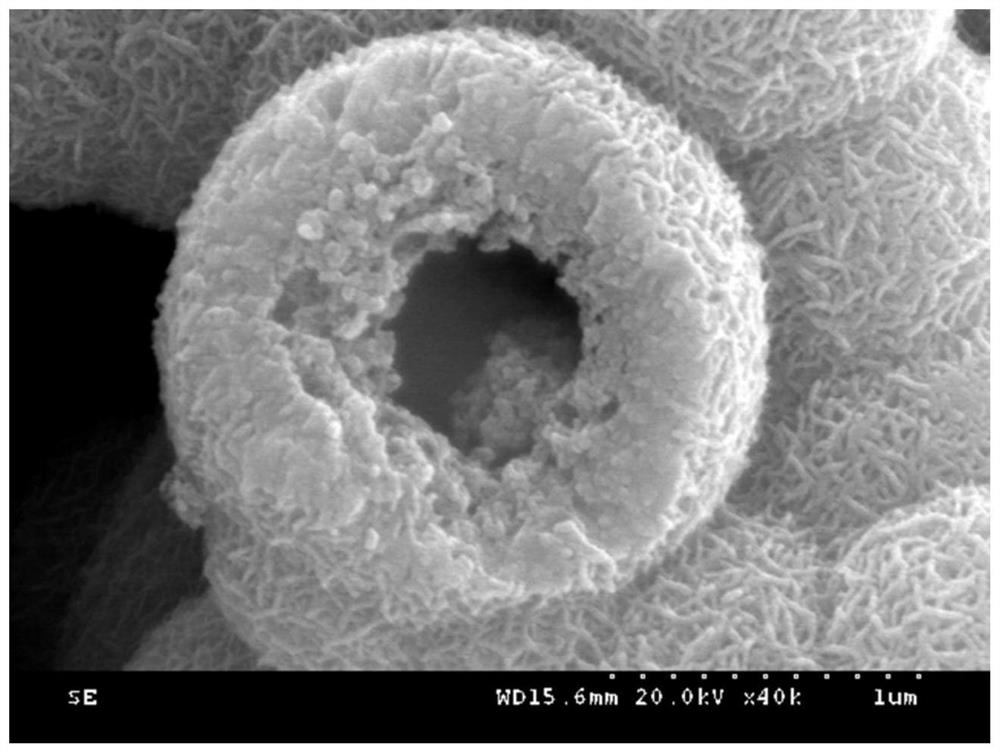

Solvothermal preparation method of NbS2 nanosheet self-assembled hollow microspheres

A hollow microsphere and nanosheet technology, which is applied in chemical instruments and methods, inorganic chemistry, niobium compounds, etc., can solve the problem that the thermal preparation method of nanosheets is not reported in literature, etc. Simple, unique looking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Measure 100ml of chloroform, remove the moisture in the chloroform by distillation with the assistance of calcium chloride or phosphorus pentoxide, and set aside.

[0025] (2) Measure 70ml chloroform, weigh 2g NbCl 5 Place in a polytetrafluoroethylene reactor liner with a capacity of 110ml, and stir for 30min.

[0026] (3) Measure 8ml of di-tert-butyl sulfide, add it to the lining of the polytetrafluoroethylene reactor and stir evenly. Close the reaction kettle, set the temperature at 220°C, and keep warm for 24 hours under magnetic stirring conditions.

[0027] (4) Centrifuge the reacted bottom sediment in a centrifuge with a rotating speed of 4000r / min, wash and centrifuge three times with deionized water and absolute ethanol respectively, and centrifuge for 5min each time to collect the washed product.

[0028] (5) The washed product was vacuum-dried at 50° C. for 4 h. For simplicity, this product is denoted as sample S1.

Embodiment 2

[0030] (1) Measure 100ml of dimethylformamide, remove the moisture in the dimethylformamide by distillation with the assistance of calcium chloride or phosphorus pentoxide, and set aside.

[0031] (2) Measure 60ml dimethylformamide, weigh 2g NbCl 5 Place in a polytetrafluoroethylene reactor liner with a capacity of 110ml, and stir for 30min.

[0032] (3) Measure 7ml of carbon disulfide, add it to the lining of the polytetrafluoroethylene reactor and stir evenly. Close the reaction kettle, set the temperature at 200°C, and keep warm for 72h under the condition of magnetic stirring.

[0033] (4) Centrifuge the reacted bottom sediment in a centrifuge with a rotating speed of 4000r / min, wash and centrifuge three times with deionized water and absolute ethanol respectively, and centrifuge for 5min each time to collect the washed product.

[0034] (5) The washed product was vacuum-dried at 50° C. for 4 h. For simplicity, this product is denoted as sample S2.

Embodiment 3

[0036] (1) Measure 100ml of acetonitrile, remove the moisture in the acetonitrile by distillation with the assistance of calcium chloride or phosphorus pentoxide, and set aside.

[0037] (2) Measure 50ml acetonitrile, weigh 2g NbCl 5 Place in a polytetrafluoroethylene reactor liner with a capacity of 110ml, and stir for 30min.

[0038] (3) Measure 10 g of thioacetamide, add it to the lining of the polytetrafluoroethylene reactor and stir evenly. Close the reaction kettle, set the temperature at 170°C, and keep warm for 24 hours under magnetic stirring conditions.

[0039] (4) Centrifuge the reacted bottom sediment in a centrifuge with a rotating speed of 4000r / min, wash and centrifuge three times with deionized water and absolute ethanol respectively, and centrifuge for 5min each time to collect the washed product.

[0040] (5) The washed product was vacuum-dried at 50° C. for 4 h. For simplicity, this product is denoted as sample S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com