Fluorenyl small-molecule semiconductor acceptor material and preparation method thereof

A technology of small molecules and semiconductors, applied in the field of fluorenyl small molecule semiconductor acceptor materials and their preparation, can solve the problems of mechanochemical technology not being obtained, achieve good chemical stability and thermal stability, low synthesis cost, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1. Synthesis of fluorenyl small molecule semiconductor (I)

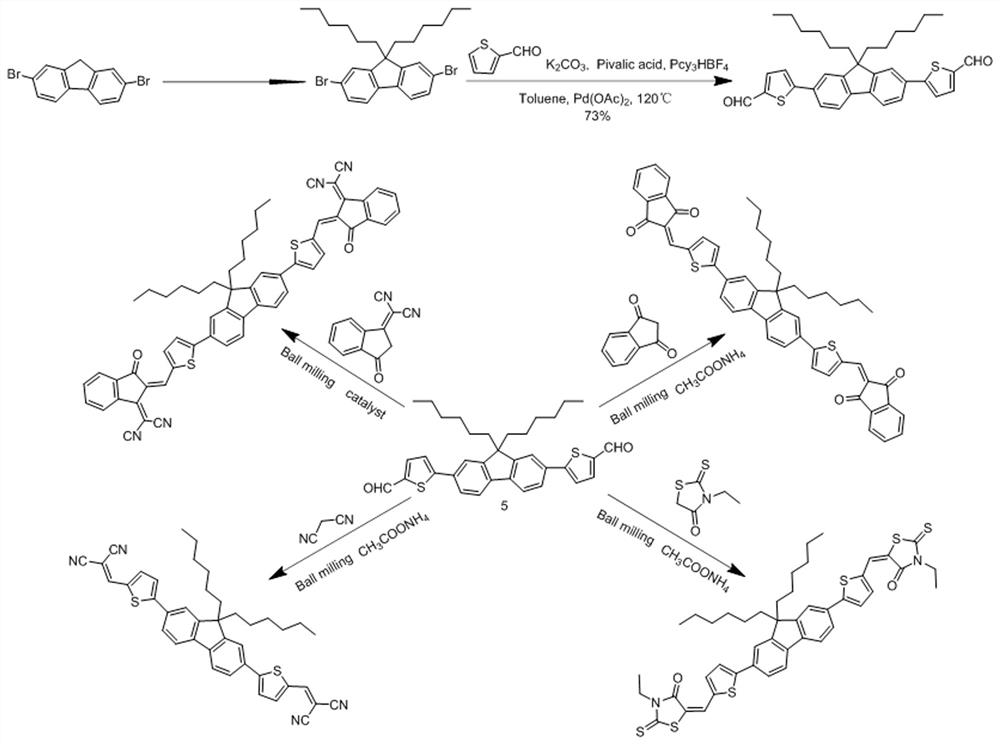

[0061] This example provides a method for synthesizing fluorenyl small molecule semiconductor (I), and its synthetic route can be found in figure 1 .

[0062] In this embodiment, the structural formula of the fluorenyl small molecule semiconductor (I) is

[0063]

[0064] The present invention optimizes the mechanical synthesis conditions of the fluorenyl small molecule semiconductor (I) several times. Firstly, the inorganic catalysts used in the mechanically carried out Norvingal condensation are searched, and ammonium acetate, sodium acetate or ammonium bicarbonate are selected. etc. as a catalyst. In addition, the mechanochemical reaction parameters of the planetary ball mill (including the size and number of stainless steel balls, and the rotational speed of the planetary ball mill) were optimized. The final optimization results are as follows:

[0065] The planetary ball mill Fukas F-P40...

Embodiment 2

[0066] Embodiment 2. Synthesis of fluorenyl small molecule semiconductor (II)

[0067] This embodiment provides a method for synthesizing fluorenyl small molecule semiconductor (II), and its synthetic route can be found in figure 1 .

[0068] In this embodiment, the structural formula of the fluorenyl small molecule semiconductor (II) is

[0069]

[0070] The present invention mainly refers to Example 1 for the mechanical synthesis conditions of the fluorenyl small molecule semiconductor (II), and optimizes the results as follows:

[0071] The planetary ball mill Fukas F-P400E was used for the reaction. The grinding balls were made of stainless steel balls with a diameter of about 6 mm, and the number was 50, accounting for 20-30% of the volume of the ball milling tank. The reaction uses ammonium acetate as a catalyst. Add monomer M1 (0.2mmol), monomer M3 (0.6mmol) and ammonium acetate (1.2mmol) into the ball mill jar, and track and monitor the entire reaction process us...

Embodiment 3

[0072] Embodiment 3. Synthesis of fluorenyl small molecule semiconductor (Ⅲ)

[0073] This embodiment provides a method for synthesizing fluorenyl small molecule semiconductor (Ⅲ), and its synthetic route can be found in figure 1 .

[0074] In this embodiment, the structural formula of the fluorenyl small molecule semiconductor (Ⅲ) is

[0075]

[0076] The present invention mainly refers to Example 1 for the mechanical synthesis conditions of the fluorenyl small molecule semiconductor (Ⅲ), and optimizes it, the results are as follows:

[0077] The planetary ball mill Fukas F-P400E was used for the reaction. The grinding balls were made of stainless steel balls with a diameter of about 6 mm, and the number was 50, accounting for 20-30% of the volume of the ball milling tank. The reaction uses ammonium acetate as a catalyst. Add monomer M1 (0.2mmol), monomer M4 (0.6mmol) and ammonium acetate (1.2mmol) into the ball mill jar, and track and monitor the entire reaction proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com