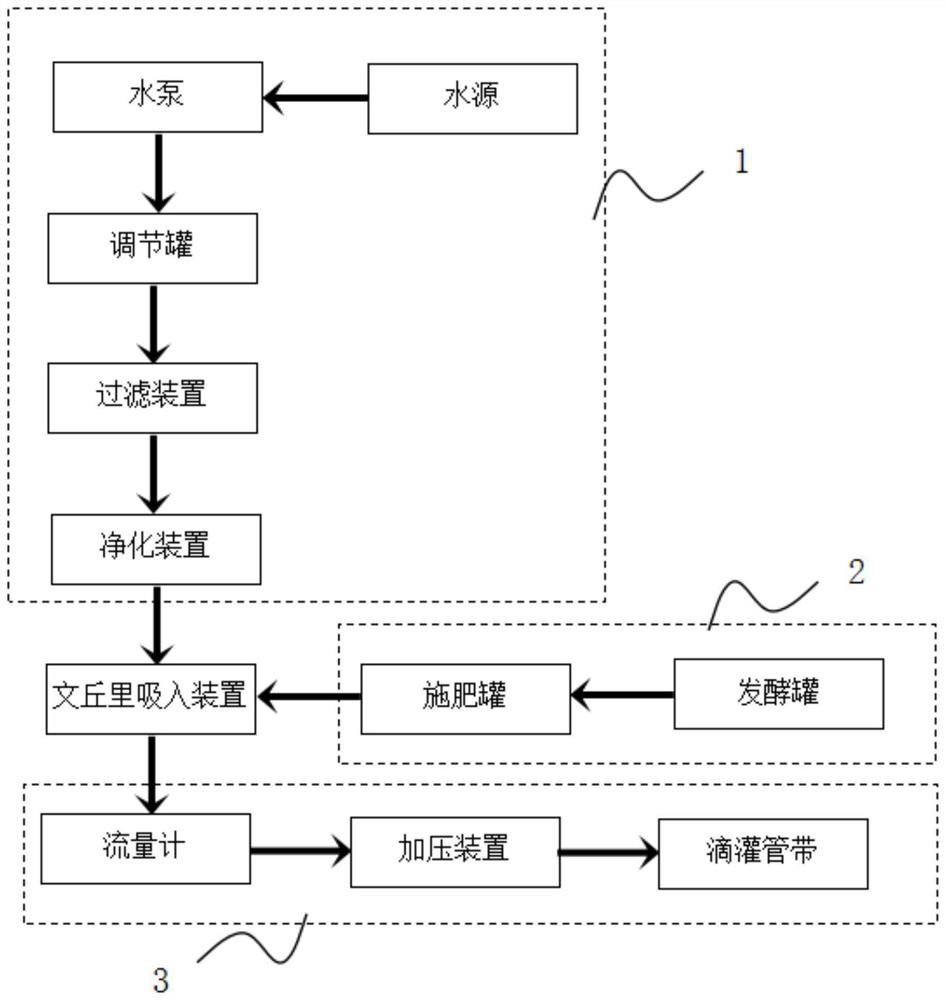

Facility cultivation water and fertilizer integrated system and facility cultivation water and fertilizer integrated fertilization method

A facility cultivation and fertilization method technology, applied in the direction of fertilization method, liquid fertilizer pressurized spreading method, fertilization device, etc., can solve the problems of low content of soluble substances and low degree of fermentation, so as to improve the degree of fermentation, improve the fermentation environment, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

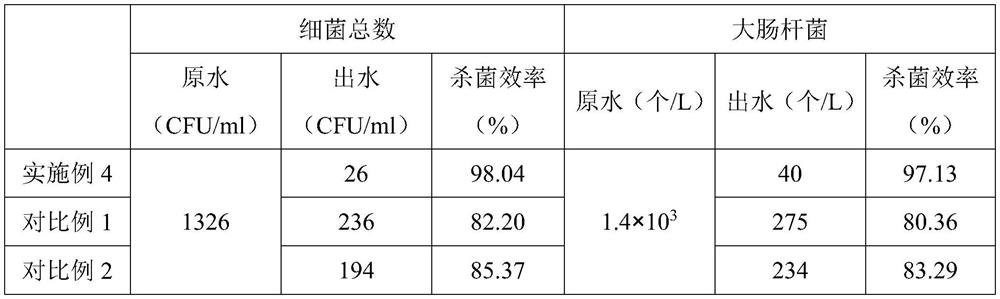

Examples

Embodiment 1

[0037] This embodiment relates to a fertilization method integrating water and fertilizer in facility cultivation, specifically fertilizing water-soluble fertilizer through a drip irrigation pipe network, wherein the preparation method of the water-soluble fertilizer includes the following steps:

[0038] S1. Dried the straw, bagasse and poultry manure and crushed to a particle size of no more than 2mm, added water to adjust the solid content to 15-16%, adjusted the pH value to 7-8, adjusted the C / N to 25:1, and added to ferment Conditioning agent, after stirring evenly and standing still, the fermentation raw material is obtained;

[0039] S2. Adding the first composite strain to the fermentation raw material and performing the first aerobic fermentation under the condition of supplying air, the fermentation temperature is 60-70° C., and the fermentation time is 10-15 days to obtain the first fermentation liquid;

[0040] Wherein, the first composite strain is a combination of ...

Embodiment 2

[0048] A fertilization method integrating water and fertilizer under facility cultivation, specifically fertilizing water-soluble fertilizer through a drip irrigation pipe network, wherein the preparation method of the water-soluble fertilizer comprises the following steps:

[0049] S1. Dried the straw, bagasse and poultry manure and crushed to a particle size of no more than 2mm, added water to adjust the solid content to 15-16%, adjusted the pH value to 7-8, adjusted the C / N to 25:1, and added to ferment Conditioning agent, after stirring evenly and standing still, the fermentation raw material is obtained;

[0050] S2. Adding the first composite strain to the fermentation raw material and performing the first aerobic fermentation under the condition of supplying air, the fermentation temperature is 60-70° C., and the fermentation time is 10-15 days to obtain the first fermentation liquid;

[0051] Wherein, the first composite strain is a combination of yeast, actinomycetes,...

Embodiment 3

[0057] With embodiment 1, the preparation method of described straw biochar is:

[0058] Peel corn, sorghum, rapeseed or cotton stalks and cut them into small pieces, wash the obtained stalks several times with deionized water and ethanol and dry them, then put them into a high-temperature atmosphere tube furnace after ball milling, and heat up in a protective atmosphere To 1000-1200 ℃, keep warm and carbonize for 60-100min, after cooling to room temperature to obtain carbonized product, immerse the carbonized product in 1-2mol / L hydrochloric acid solution to remove impurities, then wash with deionized water until neutral, and dry to prepare Obtain the straw biochar.

[0059] The solid content of the fermentation broth described in this example was measured to be 4.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com