Preparation method of high-purity manganese sulfate

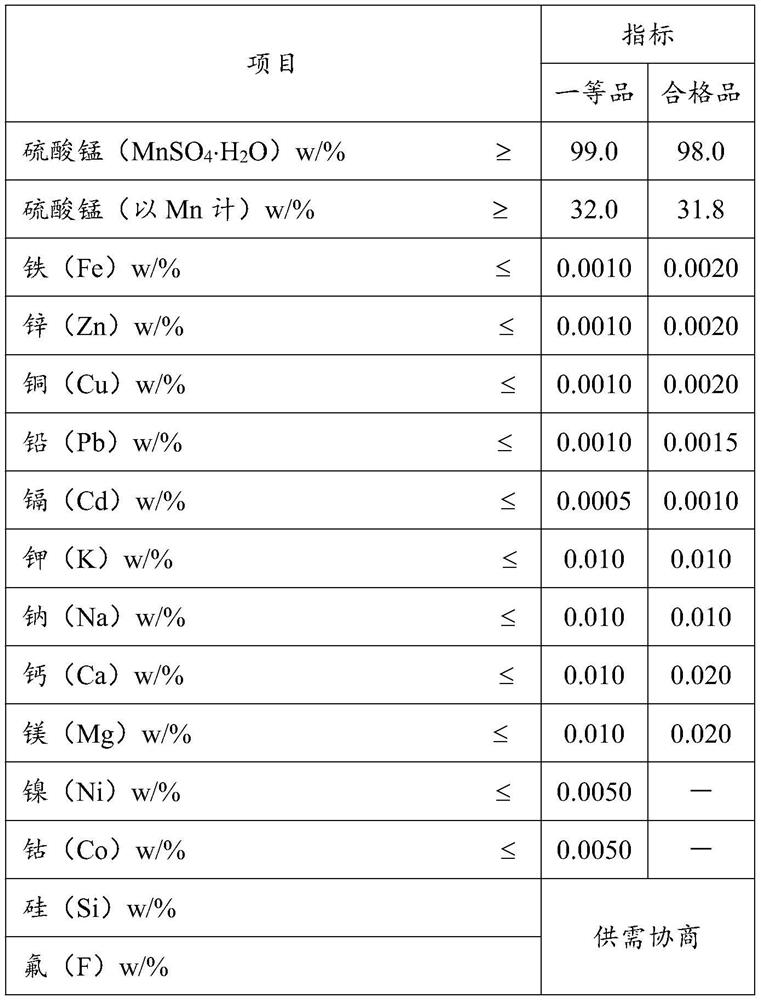

A manganese sulfate, high-purity technology, applied in manganese sulfate and other directions, can solve the problems of limited sources, reduced product purity, difficult removal of calcium and magnesium, etc., to reduce the chance of precipitation, low operating costs, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method of preparing high purity sulfate, and the method provided by the present invention can first remove calcium magnesium ions, and then remove heavy metal ions, and then remove heavy metal ions, then remove calcium magnesium ions, and will remove calcium magnesium first below The method of ion, re-removing heavy metal ions is recorded as a method, and the first removal of heavy metal ions will be removed, and the method of removing calcium magnesium ions is described as a method 2, respectively.

[0035] In the present invention, the method includes the steps of:

[0036] (1) Mix the crude manganese salt solution and pH control agent, adding a solution of ammonium bicarbonate solution to the obtained mixture, and after the addition of ammonium bicarbonate, the reaction mixture is sequentially expanded and solid-liquid separation, to obtain carbonated manganese;

[0037] (2) The manganese carbonate is dissolved in electron-level sulfuric ...

Embodiment 1

[0060] The manganese sulfate (Ca, Mg concentration of) (Ca, Mg concentration is 135 ppm and 406 ppm), and 400 g of ammonium chloride was dissolved in 2L water, and after stirring dissolved, the manganese concentration of the solution was adjusted to 100 g / L. The 1.5L solution was taken in a 10L glass reaction kettle, and heated to 102 ° C with a heat conductive oil interlayer. Under the conditions of retaining the solution temperature ≥ 102 ° C and continuously stirred, a 6 L of 30 ml / L (ammonium hydrogencarbonate: mole ratio 2.2: 1) was added to 30 mL per minute with a peristaltic pump. When necessary, the amount of boiling water is added to supplement the moisture loss due to evaporation. After the carbonate solution was completed, he was kept at 102 ° C for 1 h, and then naturally cooled to room temperature. Filter, the filter cake washed five times with high purity water. The filter cake was transferred to the beaker, slowly added 5 mol / L electron grade sulfuric acid sol...

Embodiment 2

[0062] The operation steps and Example 1 were exactly the same, only ammonium chloride was exchanged with ammonium chloride, and manganese sulfate was dried after vacuum 100 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com