Magnetic fluorinated covalent organic framework material as well as preparation method and application thereof

A technology of covalent organic framework and fluorination, applied in material separation, analytical materials, instruments, etc., can solve the problems of insufficient extraction efficiency of nanoparticles, and achieve strong magnetic response, strong adsorption selectivity, and high separation and enrichment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

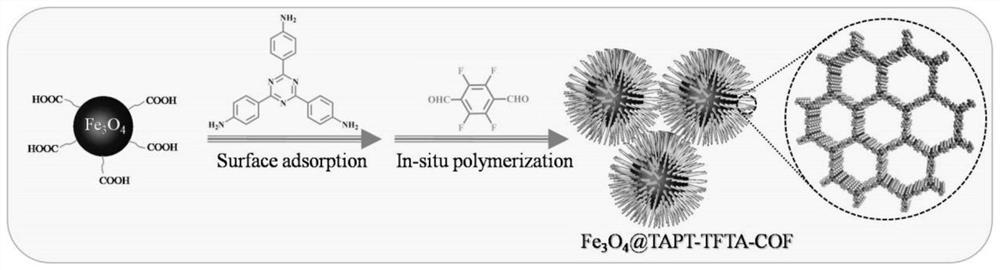

[0038] Example 1 Preparation of Magnetic Fluorinated Covalent Organic Framework Materials:

[0039] Dissolve ferric chloride hexahydrate, trisodium citrate and urea in 30mL of water at a molar ratio of 1:2:3, stir and add 300mg of polyacrylamide, transfer the mixture to a reactor after 1h, react at 200°C for 12h, and react After the end, use an external magnetic field to separate the precipitate from the reaction medium, wash it repeatedly with water and ethanol, and dry to obtain carboxylated Fe 3 o 4 nanoparticles.

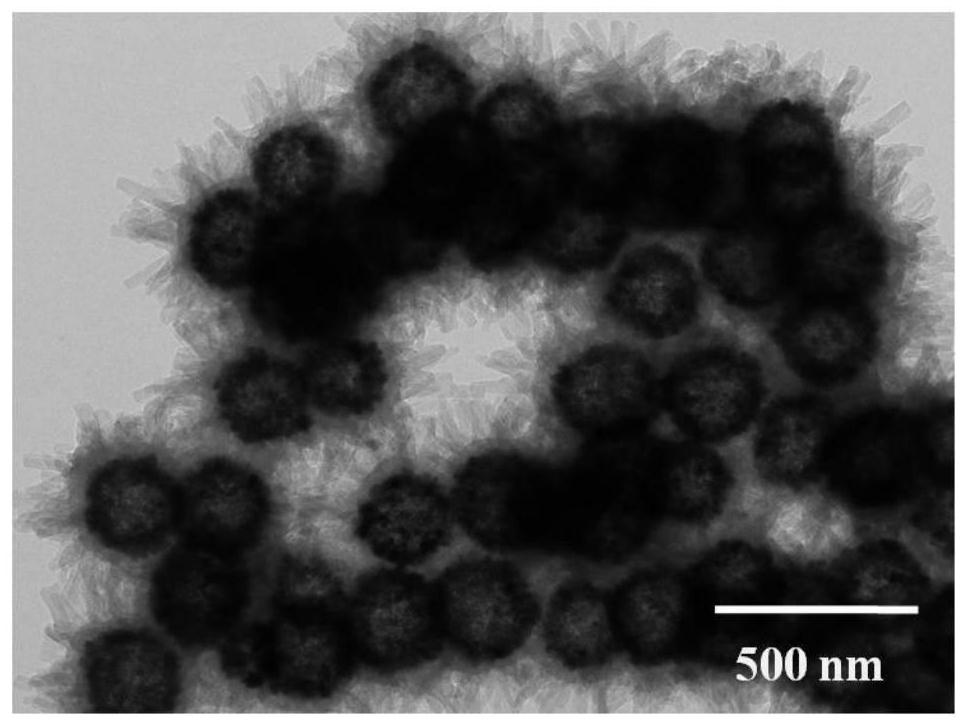

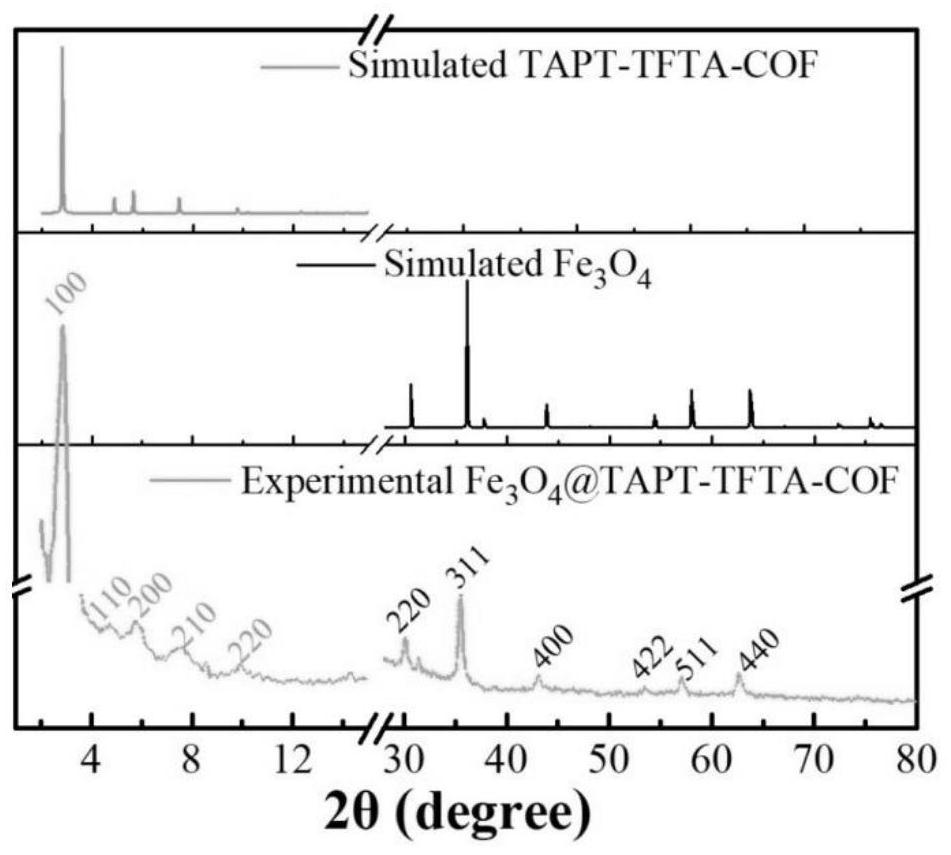

[0040] 30 mg carboxylated Fe 3 o 4 Nanoparticles were ultrasonically dispersed in 30 mL of acetonitrile, 0.24 mmol of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine was added, and after shaking at room temperature for 6 h, 0.36 mmol of 2,3, 5,6-Tetrafluoro-p-benzaldehyde and 6 mL of 12 mmol / L acetic acid were shaken at room temperature for 24 hours, magnetically separated, washed repeatedly with acetonitrile, and dried to obtain a magnetic fluorinated covalent o...

Embodiment 2

[0044] Example 2 Optimization of pretreatment conditions using magnetic fluorinated covalent organic framework materials as magnetic solid phase extraction adsorbents:

[0045] Weigh 5 mg of magnetic fluorinated covalent organic framework material into a 50 mL glass bottle, add 25 mL of water and ultrasonically disperse evenly. Add 0.5mL of benzoylurea pesticides, shake and adsorb for a certain period of time, then magnetically separate, and discard the supernatant. Next, add an appropriate amount of desorbent, after ultrasonic desorption for a certain period of time, magnetically separate and collect the eluate. Finally, nitrogen was blown to dryness and reconstituted, and after filtering with a filter membrane, the samples were injected and analyzed by liquid chromatography-mass spectrometry.

[0046] Among them, the liquid chromatography separation adopts C18 chromatographic column (100mm×2.1mm, 2.6μm), the mobile phase is 5mmol / L ammonium acetate water (C) and acetonitr...

Embodiment 3

[0052] Example 3 Cyclic performance of magnetic fluorinated covalent organic frameworks as adsorbents for magnetic solid phase extraction

[0053] Under the optimal pretreatment conditions, using the operation process of Example 2, the magnetic fluorinated covalent organic framework material that completed the first magnetic solid phase extraction process was mixed with 10 mL of methanol and 10 mL of water in sequence, and after ultrasonication for 10 min, magnetic separation was performed. Complete material regeneration. Execute the operation process of embodiment 2, compare the recovery of benzoylurea pesticides after different adsorption-desorption cycles, the results are shown in Figure 5 . After 8 cycles of use, the recovery rate of benzoylurea pesticides did not fluctuate significantly, and remained at about 90%, which indicated that Fe 3 o 4 @TAPT-TFTA-COF not only has good adsorption for benzoylurea pesticides, but also has good stability and recycling performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com