Multi-optical-performance carbon dot as well as preparation method and application thereof

A technology of optical properties and carbon dots, which is applied in the field of carbon-based nano-luminescent materials preparation, can solve the problems of powder fluorescence quenching, single optical properties of carbon dots, and difficult preparation of carbon dots, so as to expand production and preparation, save energy and time in the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 0.54 g of flaky 1,2-phenylenediamine and 0.08 g of aluminum chloride hexahydrate, place them in an agate mortar, and grind them thoroughly for 15 minutes to obtain a mixed powder.

[0033] Step 2: Transfer the mixed powder to a 25 mL reaction kettle.

[0034] Step 3: Put the hydrothermal reaction kettle in an oven and react at 200°C for 12 h.

[0035] Step 4: Naturally cool to room temperature, take out the reactor, and obtain a light gray solid powder.

[0036] Step 5: The above-mentioned solid carbon dots emit blue fluorescence under a 365 nm ultraviolet lamp, and there is a short yellow afterglow when the light source is turned off. Its fluorescence quantum yield is 3.2%, and its phosphorescent quantum yield is 2.8%.

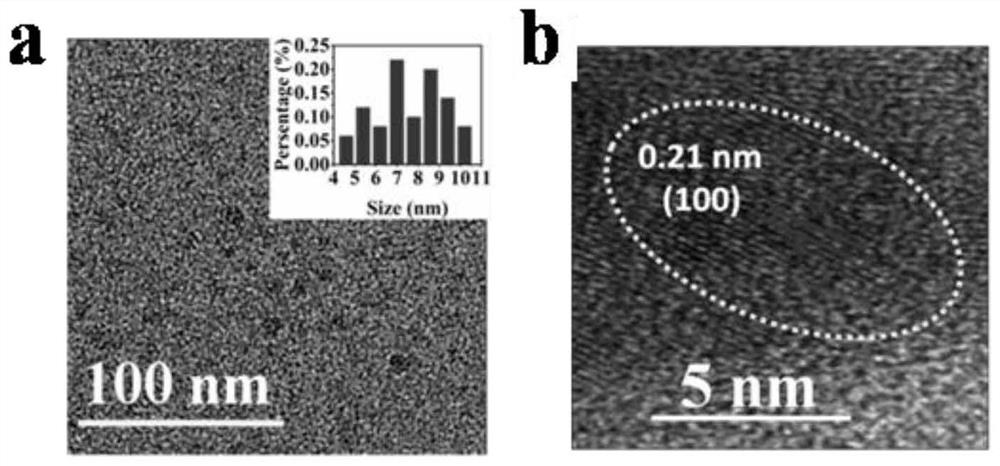

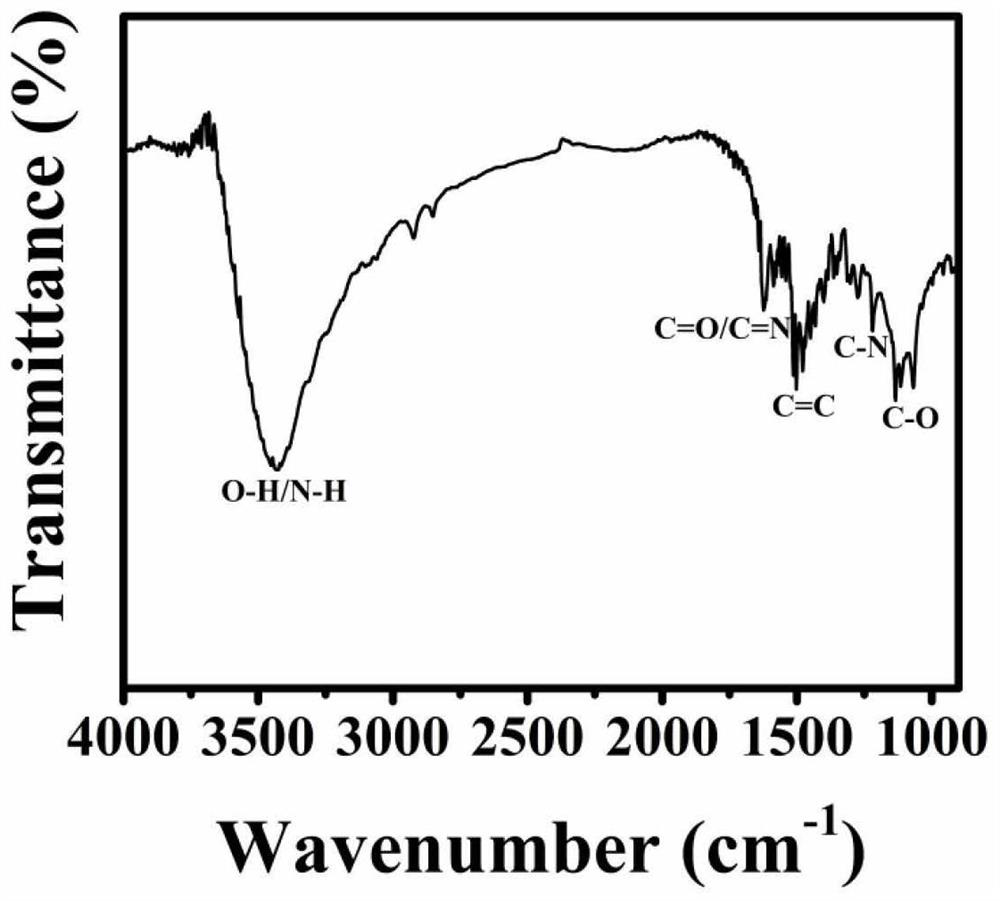

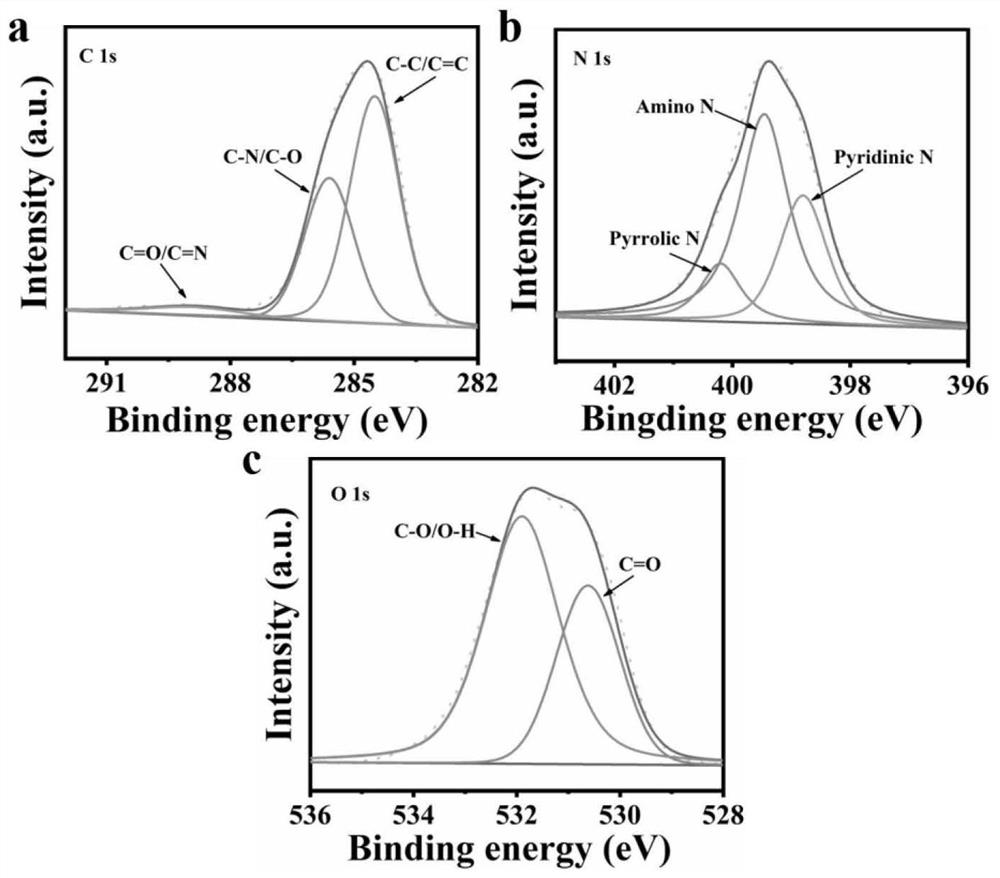

[0037] see figure 1 , the carbon dot structure appears in a, and the particle size distribution is mainly in the range of 4~10nm. The 0.21 nm lattice fringe of carbon dots in b corresponds to the 100 crystal plane of graphene, which p...

Embodiment 2

[0042] Step 1: Weigh 15 g of flaky 1,2-phenylenediamine and 1.6 g of aluminum chloride hexahydrate, place them in an agate mortar, and grind them thoroughly for 20 minutes to obtain a mixed powder.

[0043] Step 2: Transfer the mixed powder to a 100 mL reactor.

[0044] Step 3: Put the hydrothermal reaction kettle in an oven and react at 220°C for 4 h.

[0045] Step 4: Cool naturally to room temperature, and take out the reactor. A light gray solid powder was obtained.

[0046] Step 5: The above-mentioned solid carbon dots emit blue fluorescence under a 365 nm ultraviolet lamp, and there is a short yellow afterglow when the light source is turned off.

Embodiment 3

[0048]Step 1: Weigh 15 g of flaky 1,2-phenylenediamine and 1.6 g of aluminum chloride hexahydrate, place them in an agate mortar, and grind them thoroughly for 20 minutes to obtain a mixed powder.

[0049] Step 2: Transfer the mixed powder to a 100 mL reactor.

[0050] Step 3: Put the hydrothermal reaction kettle in an oven and react at 220°C for 12 h.

[0051] Step 4: Cool naturally to room temperature, and take out the reactor. A light gray solid powder was obtained.

[0052] Step 5: The above-mentioned solid carbon dots emit blue fluorescence under a 365 nm ultraviolet lamp, and there is a short yellow afterglow when the light source is turned off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com