Novel composite electrode as well as preparation method and application thereof

A composite electrode, a new type of technology, applied in chemical instruments and methods, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of high energy consumption and low light utilization rate of polycyclic aromatic hydrocarbons, achieve stable electrode performance, and benefit Regular transmission and transformation, the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

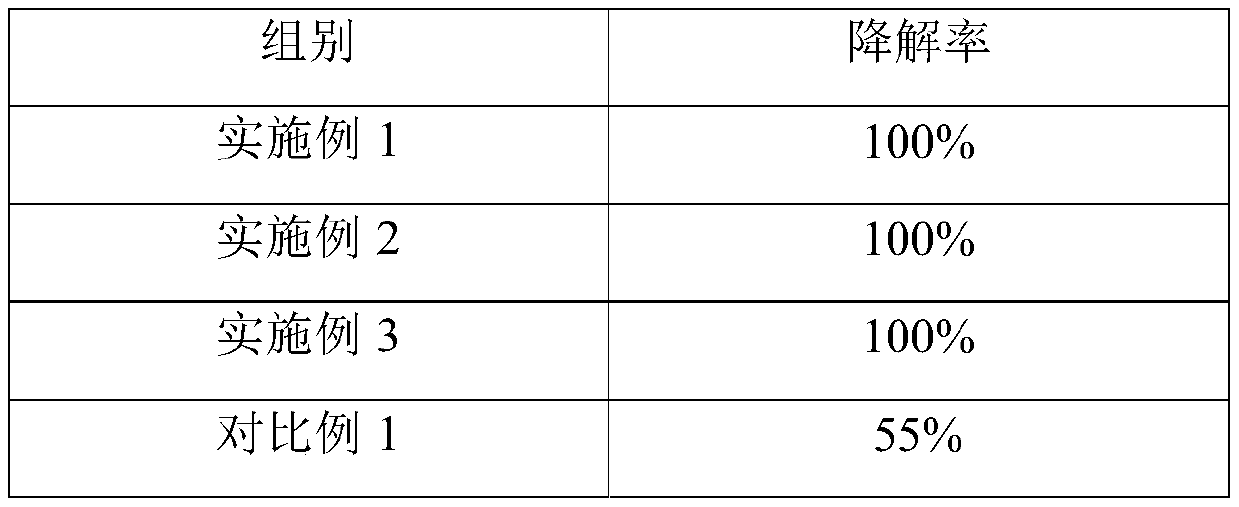

Examples

Embodiment 1

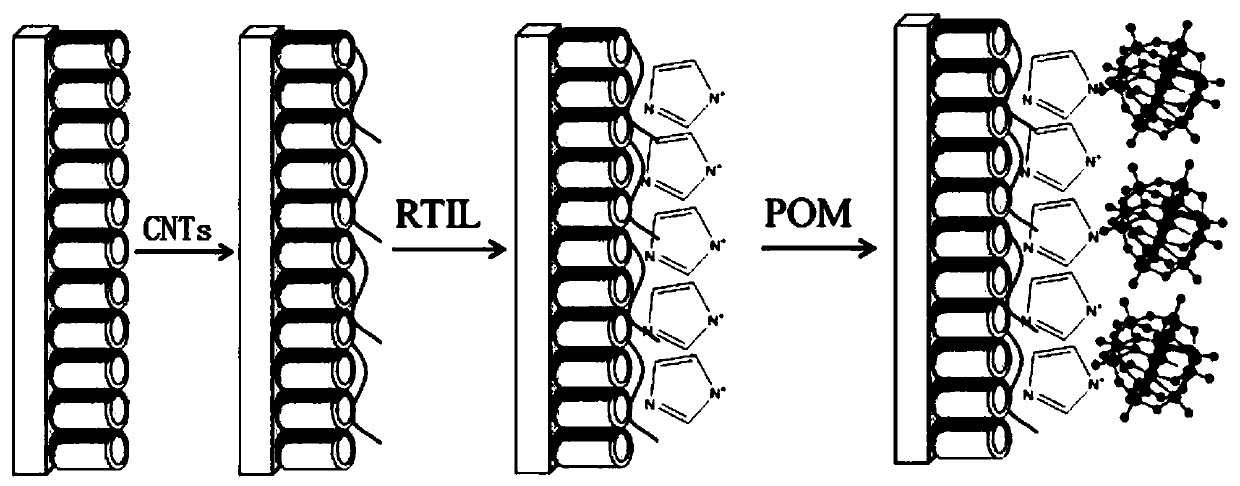

[0031] The composite electrode of this embodiment includes titanium foil, titanium dioxide nanotubes, acidified carbon nanotubes, 1-butyl-3-methylimidazolium bisulfate and phosphomolybdic acid from the inside to the outside.

[0032] The preparation method of this composite electrode is as follows:

[0033] 1. Substrate pretreatment

[0034] Grind the titanium foil with 500-mesh sandpaper to remove impurities on the surface of the titanium foil; place the polished titanium foil in acetone, ethanol, and isopropanol and ultrasonically clean the ultrasonically cleaned titanium foil with deionized water, and dry it naturally at room temperature .

[0035] 2. Preparation of titanium dioxide nanotubes

[0036] (1) Electrolyte preparation: a solution composed of ethylene glycol, deionized water and ammonium fluoride was used as the electrolyte, wherein the concentration of ammonium fluoride was 0.15 mol / L, and the volume fraction of deionized water was 4%.

[0037] (2) Anodizing: ...

Embodiment 2

[0046]The composite electrode of this embodiment comprises titanium foil, titanium dioxide nanotubes, acidified carbon nanotubes, 1-butyl-3-methylimidazole hydrochloride and phosphomolybdic acid in sequence from the inside to the outside.

[0047] The preparation method of this composite electrode is as follows:

[0048] 1. Substrate pretreatment

[0049] Grind the titanium foil with 500-mesh sandpaper to remove impurities on the surface of the titanium foil; place the polished titanium foil in acetone, ethanol, and isopropanol and ultrasonically clean the ultrasonically cleaned titanium foil with deionized water, and dry it naturally at room temperature .

[0050] 2. Preparation of titanium dioxide nanotubes

[0051] (1) Electrolyte preparation: a solution composed of ethylene glycol, deionized water and ammonium fluoride is used as the electrolyte, wherein the concentration of ammonium fluoride is 0.1mol / L, and the volume fraction of deionized water is 5%.

[0052] (2) An...

Embodiment 3

[0061] The composite electrode of this embodiment includes titanium foil, titanium dioxide nanotubes, acidified carbon nanotubes, 1-butyl-3-methylimidazolium bisulfate and phosphomolybdic acid from the inside to the outside.

[0062] The preparation method of this composite electrode is as follows:

[0063] 1. Substrate pretreatment

[0064] Grind the titanium foil with 500-mesh sandpaper to remove impurities on the surface of the titanium foil; place the polished titanium foil in acetone, ethanol, and isopropanol and ultrasonically clean the ultrasonically cleaned titanium foil with deionized water, and dry it naturally at room temperature .

[0065] 2. Preparation of titanium dioxide nanotubes

[0066] (1) Electrolyte preparation: a solution composed of ethylene glycol, deionized water and ammonium fluoride is used as the electrolyte, wherein the concentration of ammonium fluoride is 0.2mol / L, and the volume fraction of deionized water is 3%.

[0067] (2) Anodizing: the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com