A kind of preparation method and its product and application of high permeability antibacterial polyimide/chitosan composite nanofiber air filter membrane

A technology of composite nanofibers and nanofiber membranes, applied in separation methods, semi-permeable membrane separation, climate change adaptation, etc., can solve the problems of reduced effective content of chitosan, affecting antibacterial performance, etc., to reduce usage and improve Antibacterial properties, degradable and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Chitosan modification

[0035] Dissolve 2g of chitosan in 100ml of 0.5mol / L acetic acid solution, adjust the pH of the solution to 7.0, and after the temperature is adjusted to 40°C, add 0.2g of compound enzyme 1 (cellulase and lysozyme according to the mass ratio of 1:1), The reaction was shaken for 2 hours, and finally the solution was subjected to enzyme inactivation treatment to obtain a modified chitosan solution.

[0036] (2) Synthesis of polyimide / chitosan composite nanofibrous membrane

[0037] Take by weighing 36.99g dimethylacetamide (DMAc) and place in the flask, weigh 4,4'-diaminodiphenyl ether (ODA) 3.3375g respectively, pyromellitic dianhydride (PMDA) 3.708g, and ODA was put into a three-neck bottle. Fix the flask containing ODA, start the mechanical stirrer, and stir mechanically for 15 minutes to completely dissolve the monomer. Add PMDA to the flask in 10 times, and the amount added decreases as the number of times increases, and the next time is...

experiment example 1

[0055] Composite enzyme 1 (cellulase and lysozyme according to mass ratio 1:1) in embodiment 1 is replaced with papain, cellulase, lysozyme, pepsin, composite enzyme 2 (cellulase and papain according to quality Ratio 1:1), the amount of enzyme added remains unchanged, and the rest of the operations are the same as in Example 1 to prepare polyimide / chitosan composite nanofiber membranes. Afterwards, the antibacterial test and spinnability test were carried out, and the results are shown in Table 4. It can be seen from Table 4 that the chitosan was modified using the composite enzyme of cellulase and lysozyme, so that its electrospinning can be spun The antibacterial effect of the polyimide / chitosan composite nanofiber membrane prepared by it is the highest.

[0056] Spinnability Test

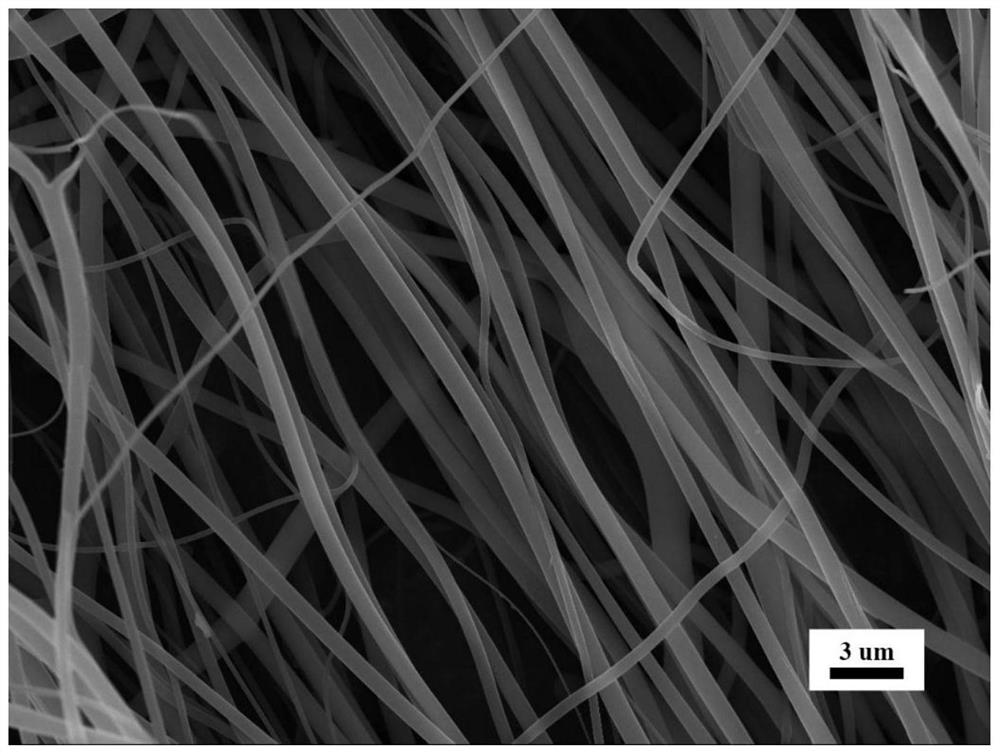

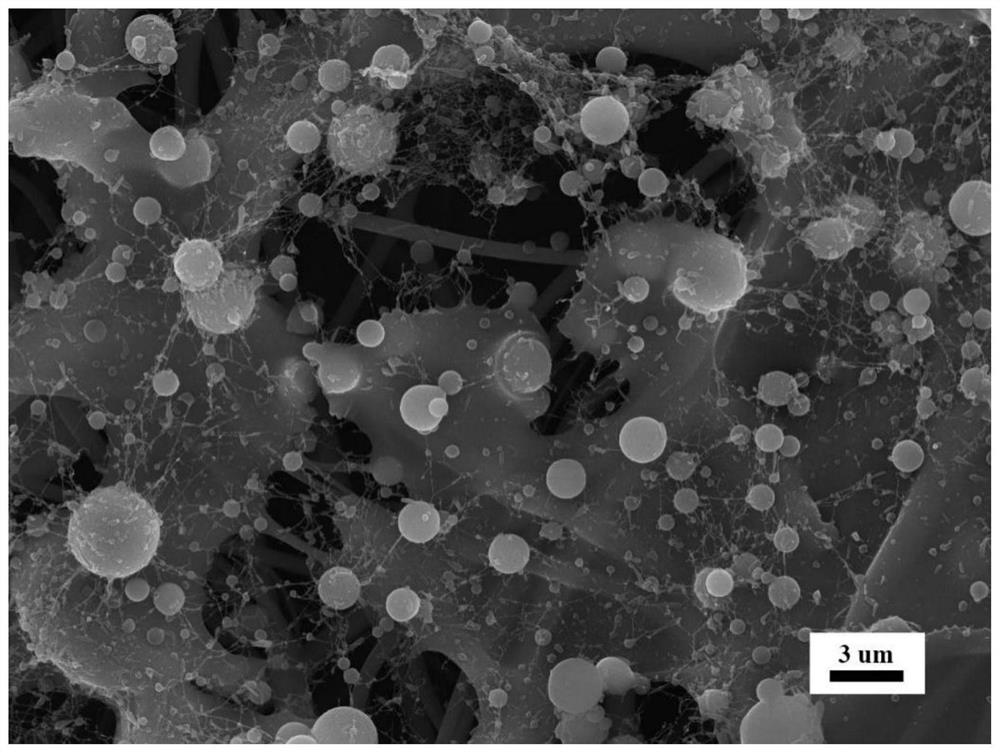

[0057] For the samples produced by electrospinning, the spinnability index can be judged by observing the fiber morphology with the naked eye combined with the SEM image. If a large amount of si...

experiment example 2

[0061] For the (1) chitosan modification step of embodiment 1, according to the orthogonal experiment of four factor three levels of table 5 design, prepare polyimide / chitosan composite nanofiber membrane according to the method for embodiment 1, by detecting Escherichia coli antibacterial rate, optimization of enzyme modification parameters. The final optimal process parameters are: temperature 40℃, time 2h, enzyme substrate mass ratio 1:10, pH 7.0.

[0062] table 5

[0063]

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com