Homogeneous Fenton cocatalyst as well as preparation method and application thereof

A catalyst-promoting and Fenton-promoting technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex operation, easy deactivation, high energy consumption, etc., and achieve the promotion of circulation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A homogeneous Fenton cocatalyst (MoS 2 ) preparation method, comprising the steps of:

[0039] 30mg MoO 3 and 83 mg of thiourea were dissolved in 30 mL of N,N-dimethylformamide, and the mixture was sonicated for 30 min at room temperature to obtain a homogeneous solution. The solution was then transferred to a 100 mL reaction kettle with a polytetrafluoroethylene liner, and heated in an oven at 200 °C for 20 h. After cooling to room temperature, the sample was washed with deionized water and absolute ethanol, and then heated at 40 °C. Dry in the oven.

Embodiment 2

[0044] A homogeneous Fenton cocatalyst (MoS 2 ) preparation method, comprising the steps of:

[0045] 1.372g(NH4) 2 MoO 4 and 1.1418 g of thiourea were dissolved in 30 mL of deionized water, and the mixture was sonicated for 30 min at room temperature to obtain a homogeneous solution. The solution was then transferred to a 100 mL reaction kettle with a polytetrafluoroethylene liner, and heated in an oven at 200 °C for 24 h. After cooling to room temperature, the sample was washed with deionized water and absolute ethanol, and then heated at 40 °C. Dry in the oven.

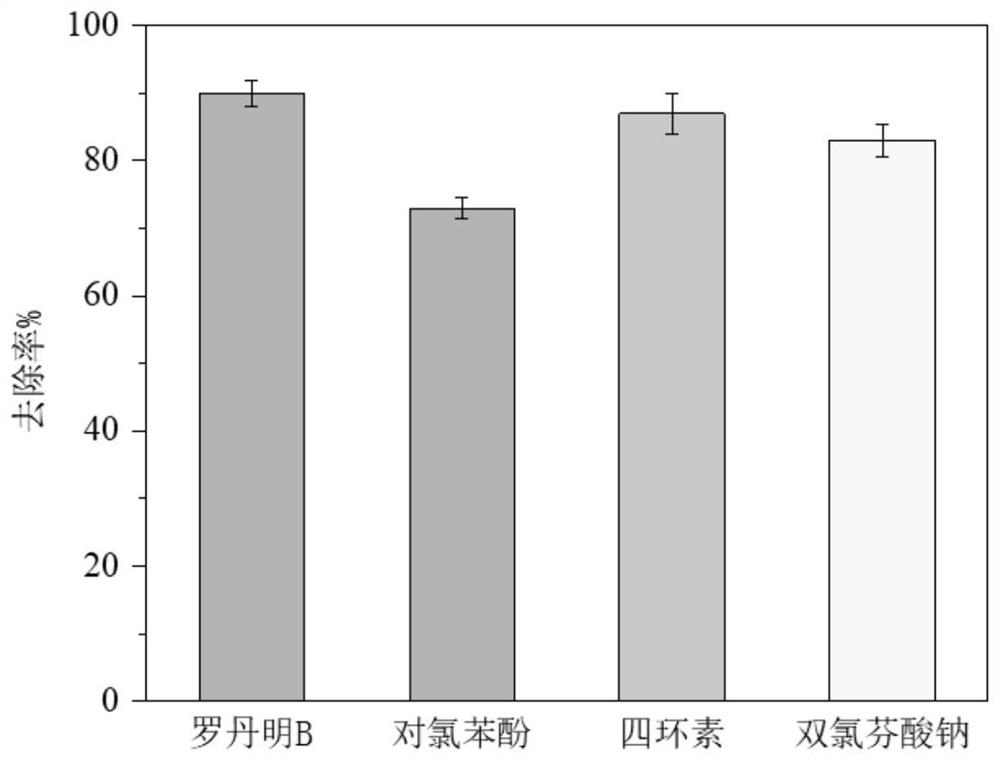

[0046] Application of Example 2: Add 0.02g of the cocatalyst synthesized above into 50mL of 5mg / L rhodamine B solution, adjust the pH value of the solution to 4.5 with 1mol / L of HCl, add 0.05mg of FeSO to the solution 4 (concentration of 1mg / L) and 0.1mmol of H 2 o 2 Then start the reaction, and after 1 hour of reaction, the removal rate of rhodamine B by this system is 70%.

Embodiment 3

[0048] A homogeneous Fenton cocatalyst (MoS 2 ) preparation method, comprising the steps of:

[0049] 0.144g MoO 3 and 2.2836 g of thiourea were dissolved in 30 mL of deionized water, and the mixture was sonicated for 30 min at room temperature to obtain a homogeneous solution. Then the solution was transferred to a 100 mL high reaction kettle with a Teflon liner, and heated in an oven at 200 °C for 24 h. After cooling to room temperature, the sample was washed with deionized water and absolute ethanol, and then heated at 40 Dry in an oven at °C.

[0050] Application of Example 3: Add 0.02 g of the cocatalyst synthesized above into 50 mL of 5 mg / L rhodamine B solution, adjust the pH value of the solution to 4.5 with 1 mol / L of HCl, and add 0.05 mg of FeSO to the solution 4 and 0.1 mmol of H 2 o 2 Then start the reaction, and after 1 hour of reaction, the removal rate of rhodamine B by this system is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com