Preparation method of super-amphiphobic antifouling transparent coating

A transparent coating and super-amphiphobic technology, applied in the coating and other directions, can solve the problems of coating performance degradation, hindering optical transparency, etc., achieve low cost, good self-cleaning effect, and improve the effect of surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

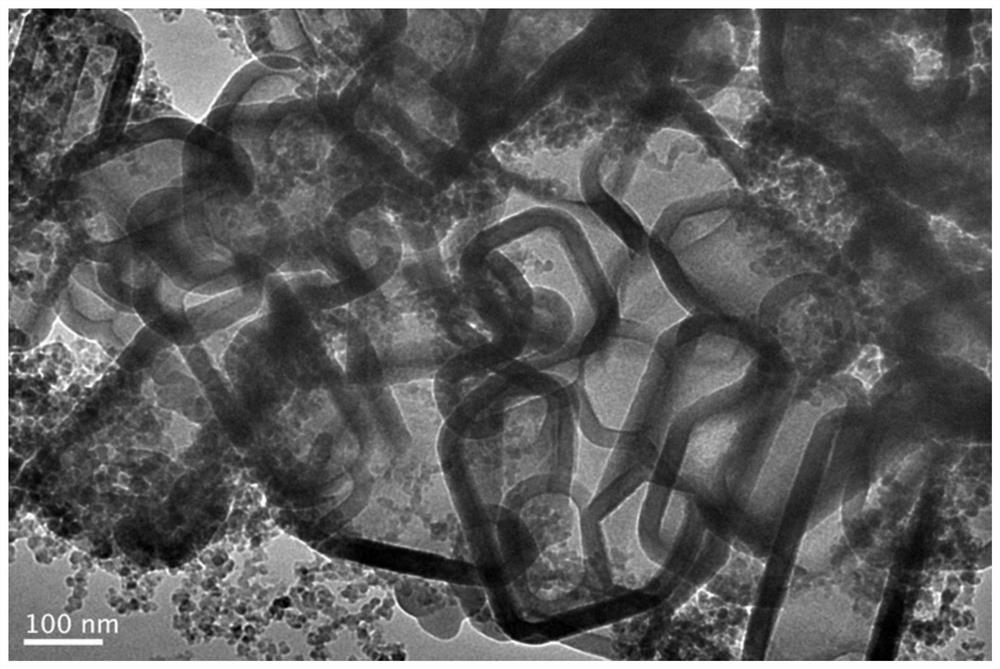

[0025] (1) Disperse ZnO into a mixed solution containing ethanol and ammonia water, stir for 5 minutes, slowly add TEOS dropwise, stir at 51°C for 4 hours, and finally centrifuge the ZnO / SiO 2 The core-shell structure was separated and washed three times with ethanol and distilled water. By controlling the molar ratio of TEOS and ZnO, ZS particles were obtained.

[0026] Among them, EtOH, TEOS and NH 4 The molar ratio of OH is 114:1:10.8, and the molar ratio of TEOS to ZnO is 0.2.

[0027] (2) Add the sample obtained in step (1) to 0.2M hydrochloric acid aqueous solution for etching until the solution turns from milky white to translucent, and then centrifuge the SiO2 with ZnO as template 2 The particles were separated and washed with distilled water and ethanol until the supernatant was neutral to obtain SZS particles.

[0028] (3) Combine the sample obtained in step (2) with gas-phase SiO 2 After mixing in mass ratio, add to 20ml of ethanol, ultrasonically disperse for 10...

Embodiment 2

[0032] (1) The preparation steps of ZS particles are the same as in Example 1. Among them, EtOH, TEOS and NH 4 The molar ratio of OH is 114:1:10.8, and the molar ratio of TEOS to ZnO is 0.2.

[0033] (2) The preparation steps of SZS particles are the same as in Example 1.

[0034] (3) The preparation steps of the coating sol are the same as in Example 1. Among them, SZS particles and gas phase SiO 2 The mass ratio is 1:3 (the total mass is 0.2g) and mixed.

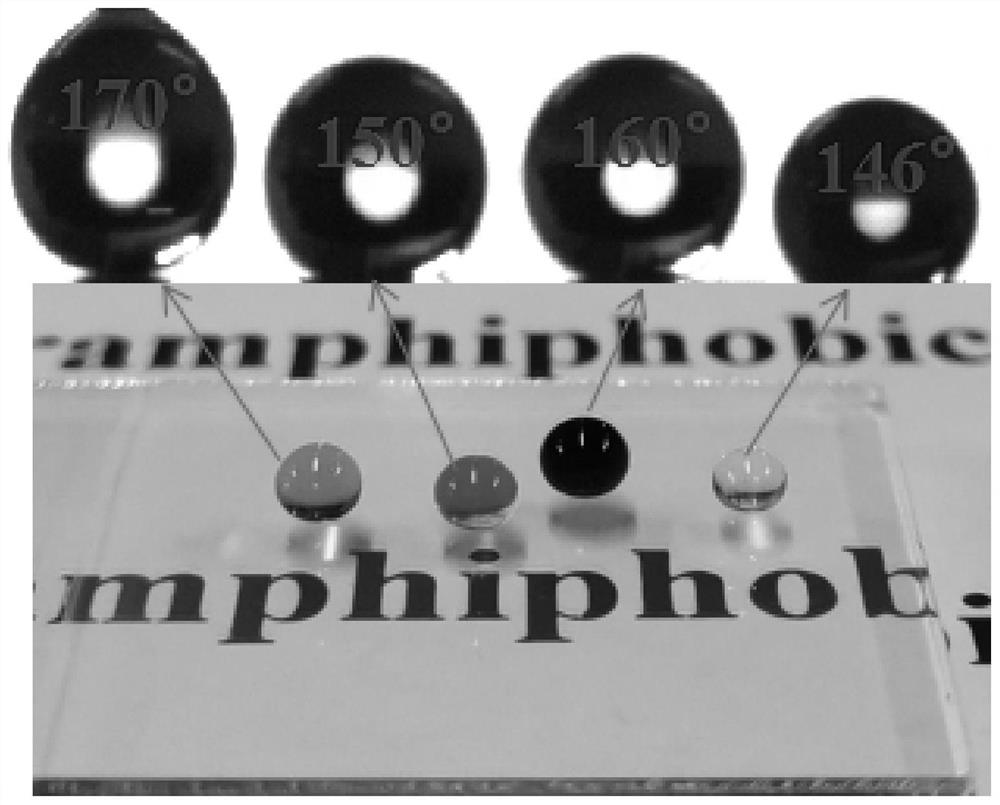

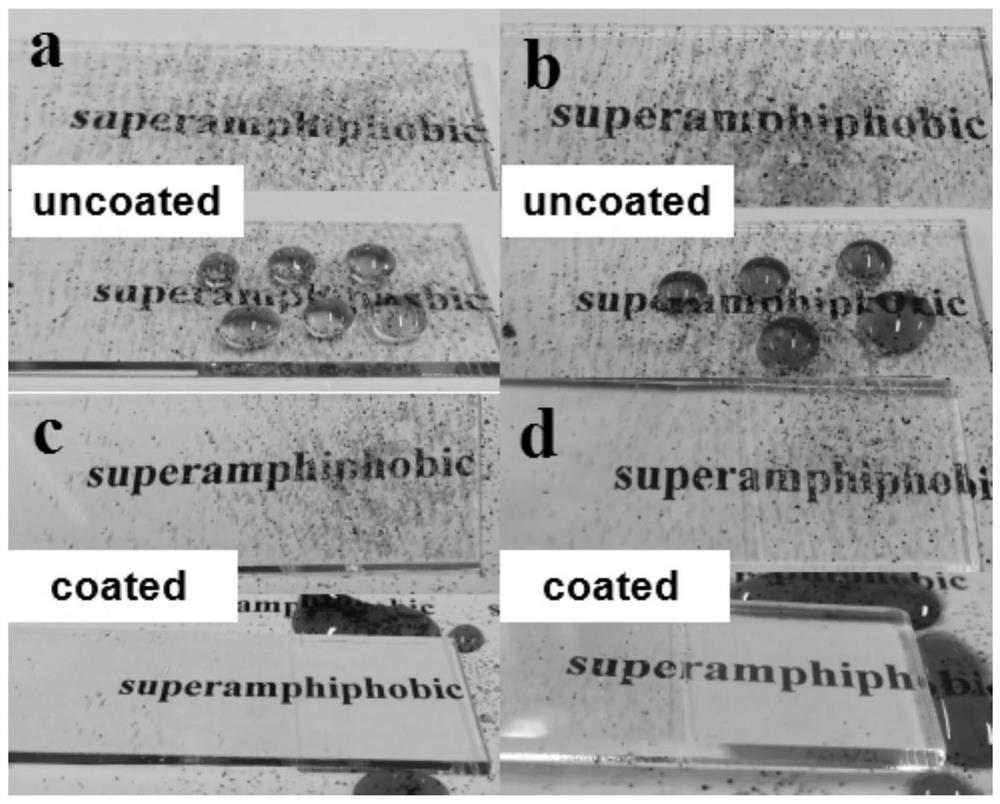

[0035] (4) The dipping-pulling method was used to plate the coating, and the plated sample was dried in an oven at 80°C for 2 hours to obtain the final superamphiphobic antifouling transparent coating. The highest light transmittance of the coating is 90.53%, and the average light transmittance is 89.14%. The measured contact angle of 5 μL water is 160°, and the rolling angle is less than 3°, the contact angle of ethylene glycol is 144°, and the rolling angle is less than 5°, and the contact angle of edible oil is 133...

Embodiment 3

[0037] (1) The preparation steps of ZS particles are the same as in Example 1. Among them, EtOH, TEOS and NH 4 The molar ratio of OH is 114:1:10.8, and the molar ratio of TEOS to ZnO is 0.2.

[0038] (2) The preparation steps of SZS particles are the same as in Example 1.

[0039] (3) The preparation steps of the coating sol are the same as in Example 1. Among them, SZS particles and gas phase SiO 2 The mass ratio is 1:7 (the total mass is 0.2g) and mixed.

[0040] (4) The dipping-pulling method was used to plate the coating, and the plated sample was dried in an oven at 80°C for 2 hours to obtain the final superamphiphobic antifouling transparent coating. The highest light transmittance of the coating is 93.15%, and the average light transmittance is 91.63%. The measured contact angle of 5 μL water is 165°, the contact angle of ethylene glycol is 145°, and the rolling angles of both are less than 3°, and the contact angle of edible oil is 135°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com