Polyether type heteropolyacid temperature control ionic liquid for removing basic nitrides of gasoline and diesel oil and preparation method thereof

A heteropolyacid anion, ionic liquid technology, applied in the treatment of hydrocarbon oil, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of complex adsorption denitrification operation process, large amount of adsorbent, low degree of automation, etc. The effect of separation, efficient removal and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Synthesis of polyether-type heteropolyacid temperature-controlled ionic liquid

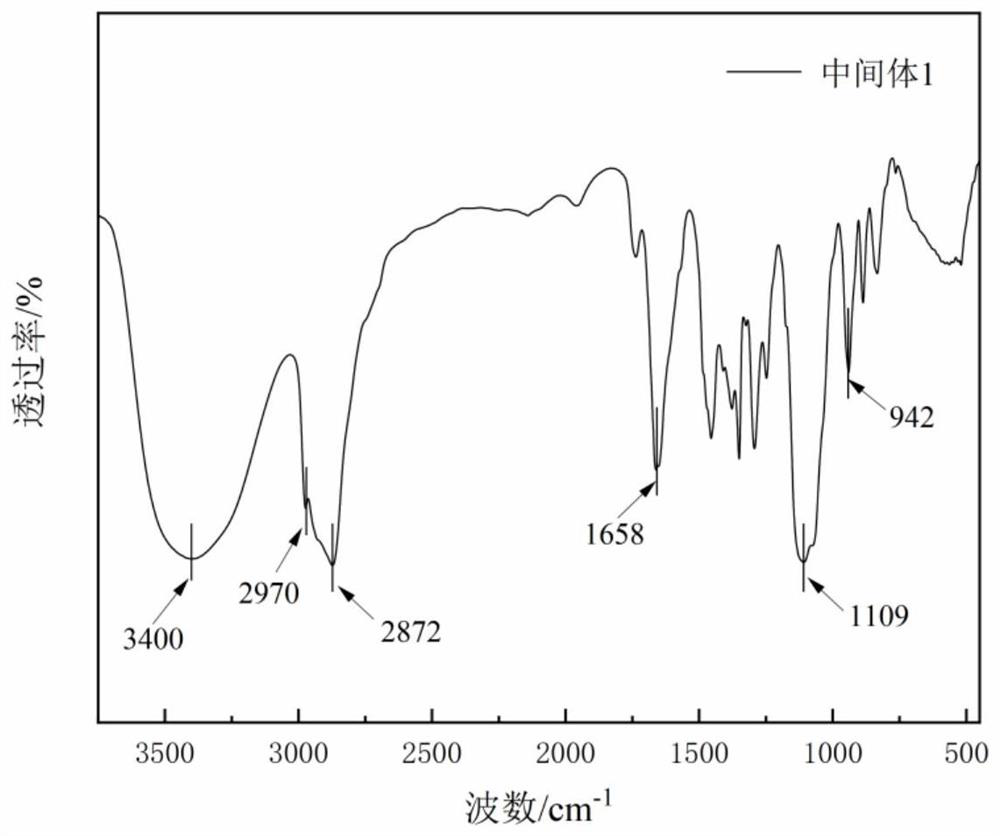

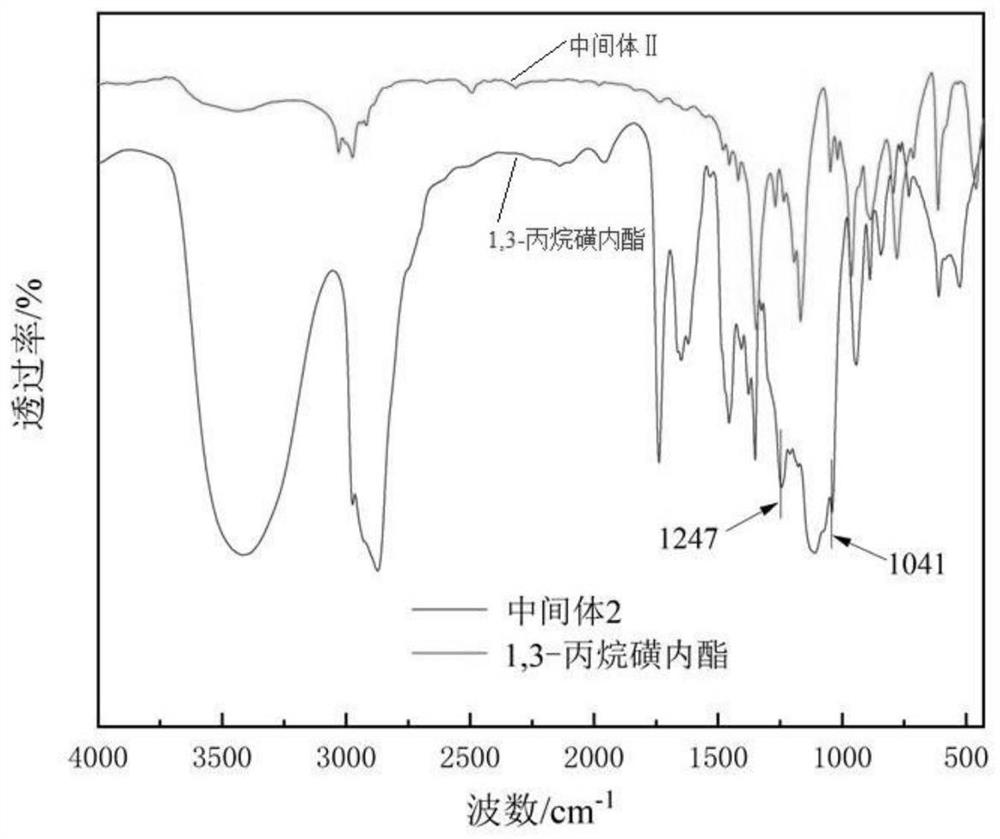

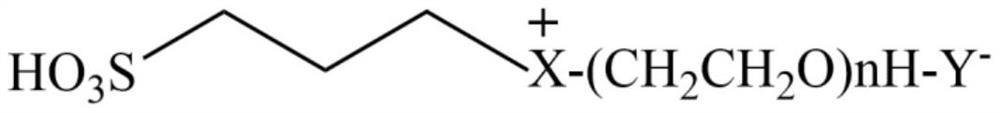

[0035]Add 0.1mol of 1,1,3,3-tetramethylguanidine (cationic liquid) and 20mL of ethanol into the autoclave, place it in the refrigerator for 12 hours, weigh 35mL of ethylene oxide and add it to the autoclave , seal the kettle, and replace the air in the kettle with nitrogen at a pressure of 3.5 MPa for 3 times. Stir and react in a water bath at 30°C for 2 hours, then raise the temperature to 70°C for 6-10 hours, lower the temperature, release the pressure, and open the kettle. The reaction solution was distilled off absolute ethanol in a round-necked flask to constant weight to obtain intermediate I, and the average degree of polymerization n was calculated according to the product weight gain method (see Table 1). Add 0.1mol of 1,3-propane sultone into the autoclave, add 30mL of ethyl acetate to dissolve it completely, add intermediate I dropwise in a water bath at 30°C according to th...

Embodiment 2

[0051] (1) Synthesis of polyether-type heteropolyacid temperature-controlled ionic liquid

[0052] As shown in Table 1, this embodiment is the same as that of Embodiment 1 except for the volume addition of cationic liquid and ethylene oxide. The specific reaction process is:

[0053]

[0054] (2) Removal of basic nitrogen compounds in simulated gasoline and diesel oil

[0055] a) Add 1 g of ionic liquid denitrification agent (n=11) to a reaction flask equipped with magnetic stirring, then add 40 g of the gasoline and diesel simulative oil (1:40) configured in Example 1, seal it, heat it in a water bath and carry out Stir magnetically and react at 50°C for 10 minutes. Stand and separate at room temperature, the upper liquid phase is the gasoline and diesel simulated oil phase after denitrification, the lower layer is the temperature-controlled ionic liquid phase, and the upper simulated oil phase is collected. Quantitative analysis was carried out by gas chromatography, a...

Embodiment 3

[0062] (1) Synthesis of polyether-type heteropolyacid temperature-controlled ionic liquid

[0063] As shown in Table 1, this embodiment is the same as that of Embodiment 1 except for the volume addition of cationic liquid and ethylene oxide.

[0064] (2) Removal of basic nitrogen compounds in simulated gasoline and diesel oil

[0065] a) Add 1 g of ionic liquid denitrification agent (n=49) to a reaction flask equipped with magnetic stirring, then add 30 g of the gasoline and diesel simulant oil (1:30) configured in Example 1, seal it, heat it in a water bath and carry out Stir magnetically and react at 50°C for 20 minutes. Stand and separate at room temperature, the upper liquid phase is the gasoline and diesel simulated oil phase after denitrification, the lower layer is the temperature-controlled ionic liquid phase, and the upper simulated oil phase is collected. Quantitative analysis was carried out by gas chromatography, and the content of basic nitrogen compounds before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com