Method for recovering valuable metals from copper dross

A technology for valuable metals and copper scum, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of inability to achieve high-efficiency separation, extraction, low comprehensive recovery capacity, waste of resources, etc., and achieve good industrialization promotion value , Improve comprehensive recycling capacity and reduce metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

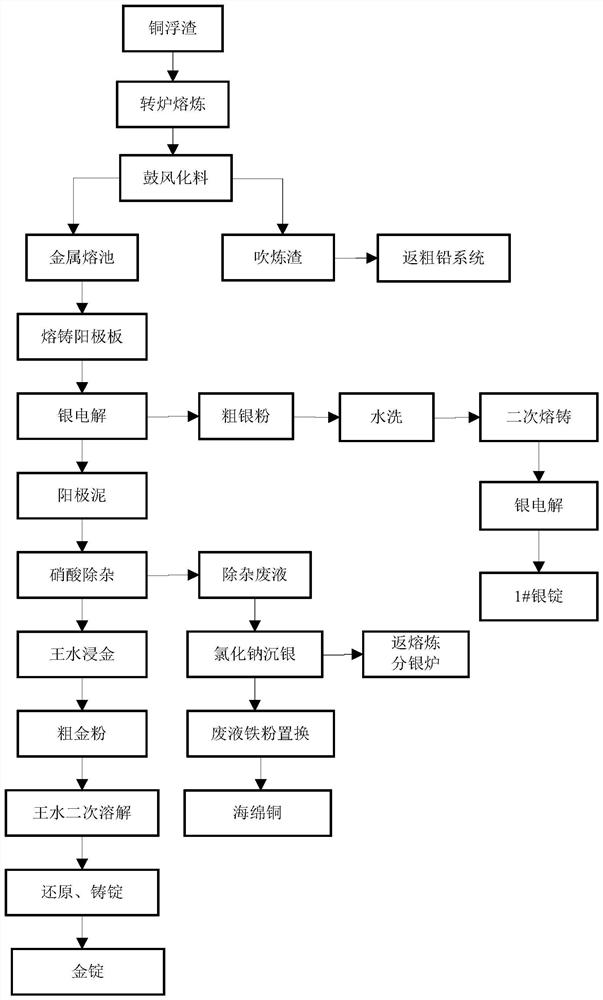

[0027] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

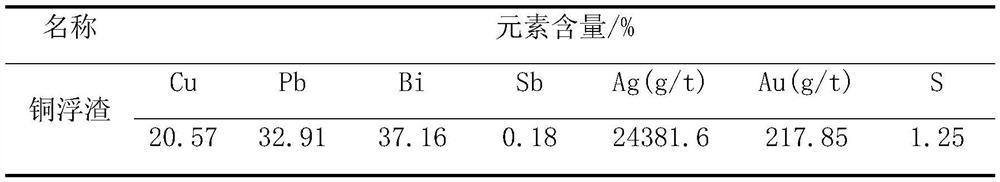

[0028] In the present embodiment: a smelter copper slag floating chemical element analysis result is as shown in table 1 below:

[0029] Table 1 Copper slag floating element analysis result (unit / %)

[0030]

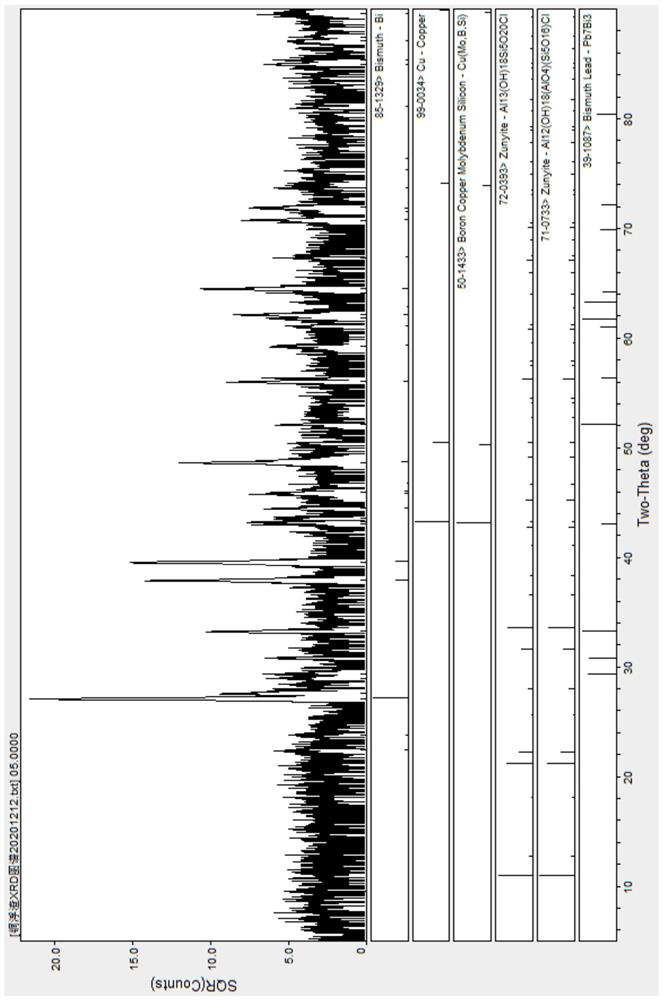

[0031] Through X-ray diffraction analysis of copper scum, it is found that copper and bismuth elements mainly exist in the form of elements, and some copper and bismuth compounds exist in the form of oxides and sulfides, such as figure 2 shown.

[0032] A total of 50t of copper scum was put into the oxidation blowing stage, and the treatment situation was judged by testing the materials in the furnace. Proceed as follows:

[0033] 1. Copper scum fire treatment:

[0034] (1) The converter in the workshop is used to process copper dross, and the converter combustion system uses an oxygen lance to increase the melting rate of materials;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com